Figure 6 operating parameters, Figure 7 npsh – Viking Pump TSM285: Classic+ Lobe Pump User Manual

Page 6

SECTION TSM 285

ISSUE

A

PAGE 6 OF 36

3.3 SySTEM DESIGN

3.3.1 SySTEM DESIGN AND

INSTALLATION

When incorporating any pump into a system it is considered

good practice to minimize piping runs and the number of pipe

fittings (tees, unions, bends etc.) and restrictions. Particular

care should be taken in designing the suction line, which

should be as short and straight as possible with a minimum of

pipe fittings to minimise restricting product flow to the pump.

The following should be considered at the design stage of any

system.

Be sure ample room is provided around the pump

to allow for:

- Access to the pump and drive for routine

inspection and maintenance, i.e. to remove

pump head and rotors.

- Ventilation of the drive to prevent over

heating.

The exterior of the pump unit may exceed 68°C

(154°F); Appropriate measures must be taken to

warn or protect operators.

The pump must not be used to support piping.

All piping to and from the pump unit must be

independently supported. Failure to observe

this may distort the pump head components

or assembly and cause serious consequential

damage to the pump.

Valves should be provided adjacent to the pump suction and

discharge connections to allow the pump to be isolated from

the system for routine inspection and maintenance.

Rotary lobe pumps are of the positive displacement

type and therefore an overload protection device

must be provided. This can take the form of:

- An in-line pressure relief system, i.e. external

to the pump.

- Incorporation of a torque-limiting device in the

drive system.

It is recommended that all piping and associated

equipment from the tank to the discharge point

is thoroughly cleaned before installation of the

pump to avoid the possibility of debris entering

the pump and causing damage.

Pressure gauges should be installed adjacent to

the pump suction and discharge connections such

that system pressures can be monitored. These

gauges will provide a clear indication of changes

in operating conditions and where a relief valve

is incorporated in the system, will be necessary

for setting and checking the functioning of the

valve.

It is imperative that the suction condition at the

pump inlet meets the Net Positive Suction Head

required (NPSHr) by the pump. Failure to observe

this could cause cavitation, resulting in noisy

operation, reduction in flow rate and mechanical

damage to the pump and associated equipment.

The Net Positive Suction Head available

(NPSHa) from the system must always exceed

the Net Positive Suction Head required (NPSHr)

by the pump.

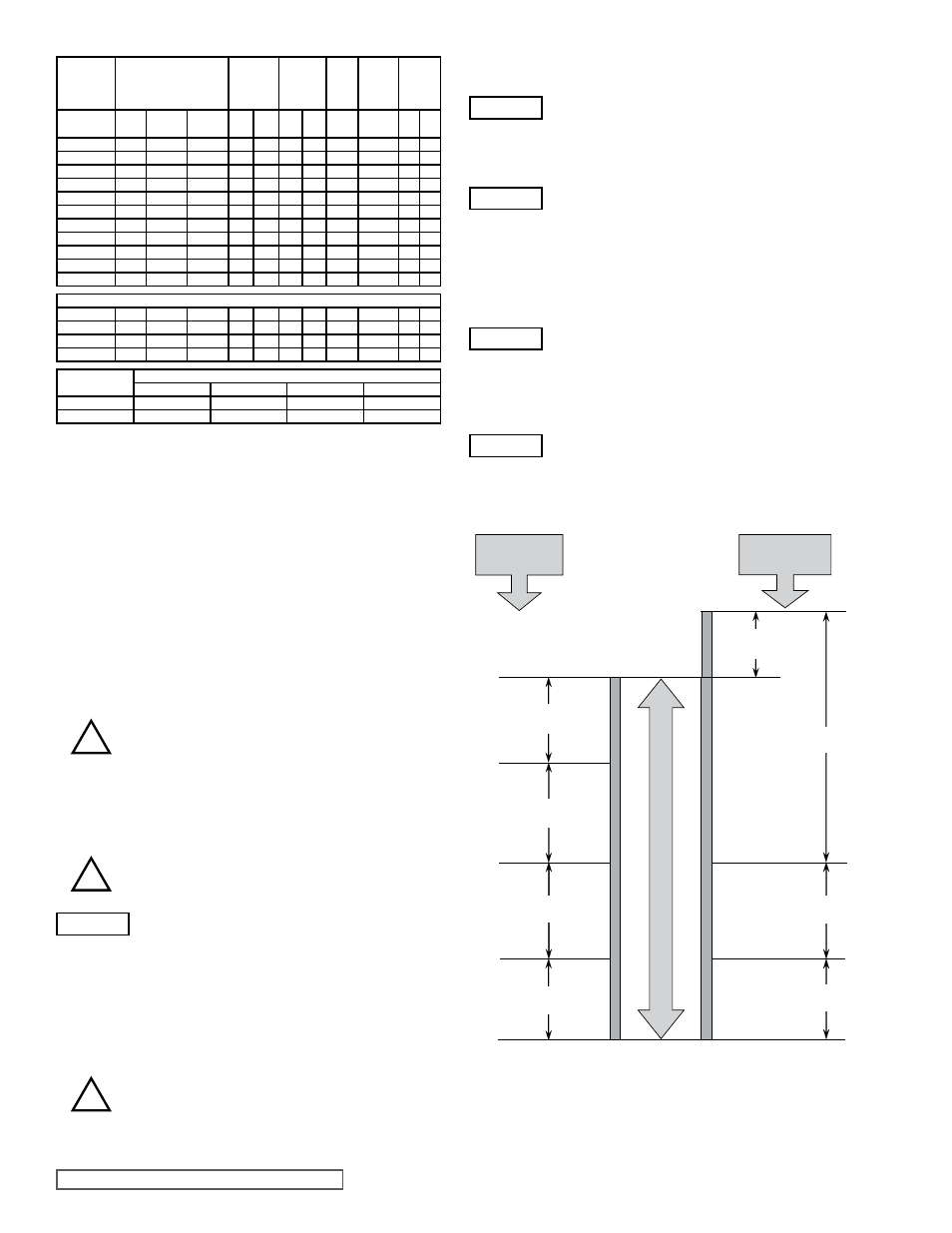

Pump Range

Theoretical Displacement

Nominal

Connection

Size

Max

Differential

Pressure

Max.

Speed

Max

Speed @

Max Diff.

Pressure

Max Diff.

Pressure

@ Max

Speed

ltr/rev Imp.gal

/100 rev

US gal

/100 rev mm

in.

bar psi

rev/

min

rev/min bar psi

CP10S

0.046

1.01

1.22

25

1

12

175

1400

1000

8.5 120

CP10M

0.083

1.83

2.19

38

1.5

8

120

1400

1000

5.5 75

CP10L

0.111

2.44

2.93

38

1.5

5

70

1400

1000

3.5 50

CP20S

0.202

4.44

5.34

38

1.5

12

175

1000

750

8.5 120

CP20L

0.313

6.89

8.27

50

2

7

100

1000

750

5.0 70

CP30S

0.694

15.27

18.34

50

2

12

175

750

550

8.5 120

CP30L

1.125

24.75

29.72

76

3

7

100

750

550

5.0 70

CP40S

1.800

39.60

47.56

76

3

12

175

700

520

8.5 120

CP40L

2.500

55.00

66.05

101

4

7

100

700

520

5.0 70

CP50S

3.514

77.31

92.84

101

4

12

175

650

420

8.5 120

CP50L

5.250

115.50

64.20

152

6

8

115

600

420

5.5 75

CP20/CP30 High Efficiency Operating Parameters.

CP20S

0.202

4.44

5.34

38

1.5

7

100

1000

750

5.0 70

CP20L

0.313

6.89

8.27

50

2

4

55

1000

750

3.0 40

CP30S

0.694

15.27

18.34

50

2

7

100

750

520

5.0 70

CP30L

1.125

24.75

29.72

76

3

4

55

750

520

3.0 40

Classic+ Series

Operating Temperature Limit (°C)

Class A

Class B

Class C

Class D

CP10, 20, 30, 40

70

100

150

N/A

CP50

N/A

100

N/A

180

figure 6

Operating Parameters

10

.0

M

et

er

s

(3

2.

8

Fe

et

)W

at

er

C

ol

um

n

Suction Lift

Or Vacuum

Atmospheric

Pressure

Suction

Head

NPSH

Available

Suction Line

Friction Loss

Vapour

Pressure

NPSH

Available

Suction Line

Friction Loss

Vapour

Pressure

For Suction Lift

Or Vacuum

Conditions.

For Conditions

With Positive

Suction Head.

Atmospheric

Vacuum

figure 7

NPSH

!

WARNING

!

!

WARNING

WARNING

WARNING

WARNING