5 cp50 casing, rotor and head assembly – Viking Pump TSM285: Classic+ Lobe Pump User Manual

Page 24

SECTION TSM 285

ISSUE

A

PAGE 24 OF 36

- Be sure faces of spacers’ (5.24) are parallel after

machining.

- After any machining of spacers’ (5.24), check front clearances

for both rotors, refer to section 8.1, Clearance Chart.

- Install spacers (5.24) to shafts (5.01 and 5.02) ensuring they

are correctly located.

- Install pins (5.23) to shafts (5.01 and 5.02) using a liquid

retainer (Loctite 648 or similar).

- Install product seals; refer to section 5.3 and 6.3.

- Install casing (3.01) to gearbox (4.01) locating onto dowels

(4.03) and securing with dome nuts (4.08) tightened to

correct torque, refer to section 8.2.

- Install O-rings (2.05) and rotors (2.01) to shafts (5.01 and

5.02).

- Lubricate retainers’ (53) with oil and install to shafts (5.01

and 5.02).

- Clamp one rotor (2.01) to shaft (5.01 or 5.02) using tool and

associated stud and nut, see Figure 48, ensuring that two

of the screws in retainer (2.05) are visible through holes in

tool.

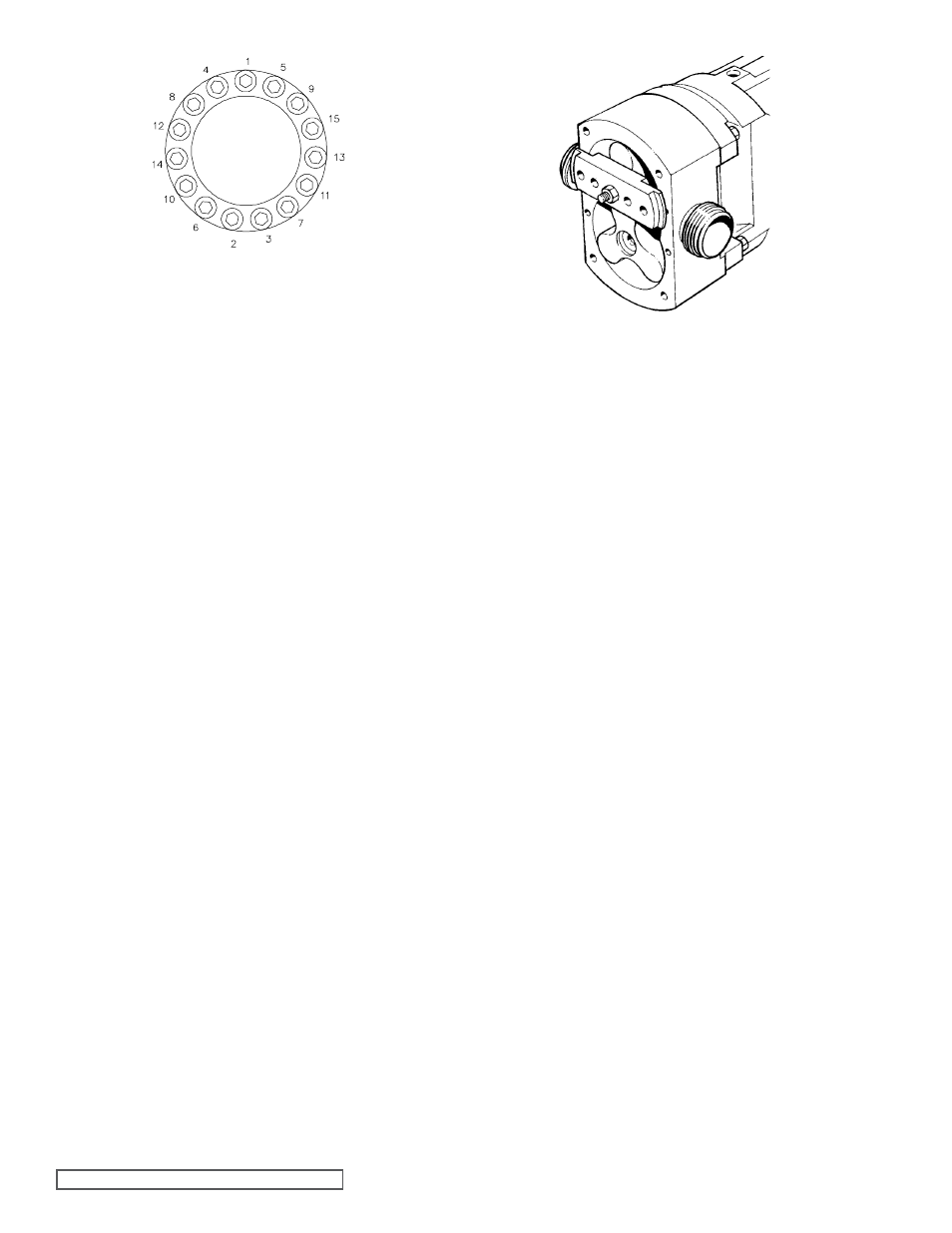

- Moderately tighten visible screws in retainer (2.05) in clamped

rotor to lock rotor in position. Remove tool and associated

stud and nut, tighten fully screws in retainer (2.05) to correct

torque, refer to section 8.2, taking note of typical tightening

sequence, see Figure 47.

- Repeat clamping and retainer (2.05) tightening procedure for

other rotor.

- Remove tool and associated stud and nut.

- Install O-rings (2.03) and retainers (2.02) tightening to correct

torque refer to section 8.2, using tool.

- Check all rotor clearances, front, rear, top/bottom, sides’ and

mesh, refer to section 8.1, Clearance Chart.

- Install head (1.01) with O-ring (1.02) and secure with nuts

(1.03) tightened to correct torque, refer to section 8.2.

- Install oil seal (6.03) to gearbox cover (6.00).

- Apply liquid sealant (Loctite 573 or similar) to sealing area of

gearbox cover (6.00) and install to gearbox (4.01), locating

on dowels (6.06) and securing with screws (6.11), tightened

to correct torque, refer to section 8.2.

- Install drive key (6.12).

- Install drain plugs (6.09) and breather plugs (6.10).

- Remove rotor retainers (2.02) using tool, rotors (2.01) and

spacers (5.24)

4.3.5 CP50 CASING, ROTOR AND

HEAD ASSEMbLy

Referring to Figure 33 and Figure 44.

- Install spacers’ (5.24) and product seal sleeves (7.15) to

shafts (5.01 and 5.02).

Note: Pins (5.23) should not be installed at this stage.

- Install casing (3.01) to gearbox (4.01) locating on dowels

(4.03) and secure with dome nuts (4.08) tightened to correct

torque, refer to section 8.2.

- Install rotors (2.01) to shafts (5.01 and 5.02).

- Clamp one rotor (2.01) to shaft (5.01 or 5.02) using tool and

associated stud and nut see Figure 48.

- Using a depth micrometer or similar device, measure front

clearance; refer to section 8.1, Clearance Chart, between

the casing and clamped rotors front face and check that this

corresponds to the appropriate clearance as indicated on the

Clearance Chart. Note any discrepancy in front clearance.

- Remove tool and associated stud and nut (shown above).

- Repeat clamping and front clearance measurement for other

rotor (again note any discrepancy in front clearance.

- Remove tool and associated stud and nut.

- Remove rotors (2.01), casing (3.01) and product seal sleeves

(7.15).

- If any discrepancies were noted in front clearances, between

rotors and front face of casing, then spacers (5.24) will

require machining to shorten them to achieve the correct

front clearance, refer to section 8.1.

Note: If it is found that the measured front clearance is

greater than that shown in the Clearance Chart, refer

to section 8.1, then new spacers (5.24) will need to be

obtained and machined to the correct lengths to achieve

correct front clearance.

figure 48

Rotor Clamping Tool fitment

figure 47

Retainer Tightening Sequence