Viking Pump TSM285: Classic+ Lobe Pump User Manual

Page 13

SECTION TSM 285

ISSUE

A

PAGE 13 OF 36

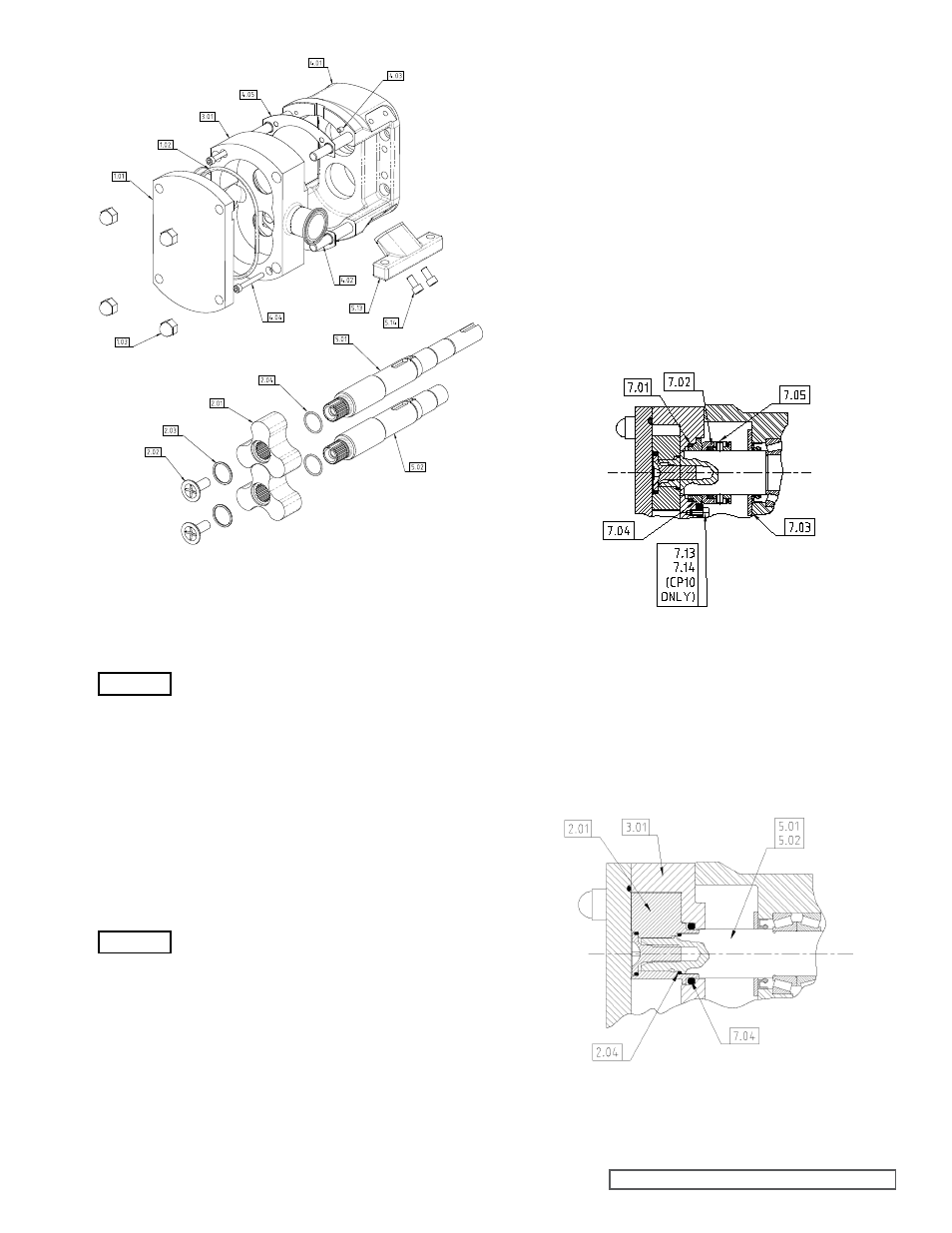

Single O-ring Seal as shown in Figure 18 – see section 6.2.1

for removal and replacement.

- Remove rotor (2.01).

- Remove O-ring seal (7.04) from casing (3.01).

Note: The socket tool should always be

used, the use of other tools may damage the

retainer.

- Remove retainer O-rings (2.03).

- Remove rotors (2.01) from shafts (5.01 and 5.02).

- Remove rotor O-rings (2.04) – Not fitted on O-ring seal

version of CP10.

Note: If the pump is fitted with O-ring Seals (instead of

mechanical seals) then the O-ring seal will now be visible

– Chapter 6.0 for further information.

4.1.2 CP10, CP20 AND CP30

CASING REMOVAL

Note: Ensure all pipe work is disconnected

before commencing casing removal.

4.1.2.1 CP10, CP20 AND CP30

CASING REMOVAL

fOR PUMPS fITTED WITH

SINGLE UN-fLUSHED

MECHANICAL SEALS AND

SINGLE O-RING SEALS

CP10 Pump Only

(After completing section 4.1.1)

- Slide casing (3.01) from bearing housing (4.01), noting

it is located on dowels (4.03), keep arch shims (4.05) in

appropriate sets if they are to be reused.

CP20 and CP30 Pump Only

(After completing section 4.1.1)

- Remove casing retention socket cap head screws (4.04)

with appropriate metric allen key (not supplied).

- Slide casing (3.01) from bearing housing (4.01), noting

it is located on dowels (4.03), keep arch shims (4.05) in

appropriate sets if they are to be reused.

Single Un-Flushed Mechanical Seal as shown in Figure 17.

- See section 5.2.1 for removal and section 5.2.2 for

replacement.

figure 17

Single Un-flushed Mechanical Seal

figure 16

CP20/CP30 Exploded View of Casing

and Rotor Assembly

figure 18

O-ring Seal

WARNING

WARNING