5 cp50 double flushed mechanical seal removal, 6 cp50 double flushed mechanical seal replacement – Viking Pump TSM285: Classic+ Lobe Pump User Manual

Page 29

SECTION TSM 285

ISSUE

A

PAGE 29 OF 36

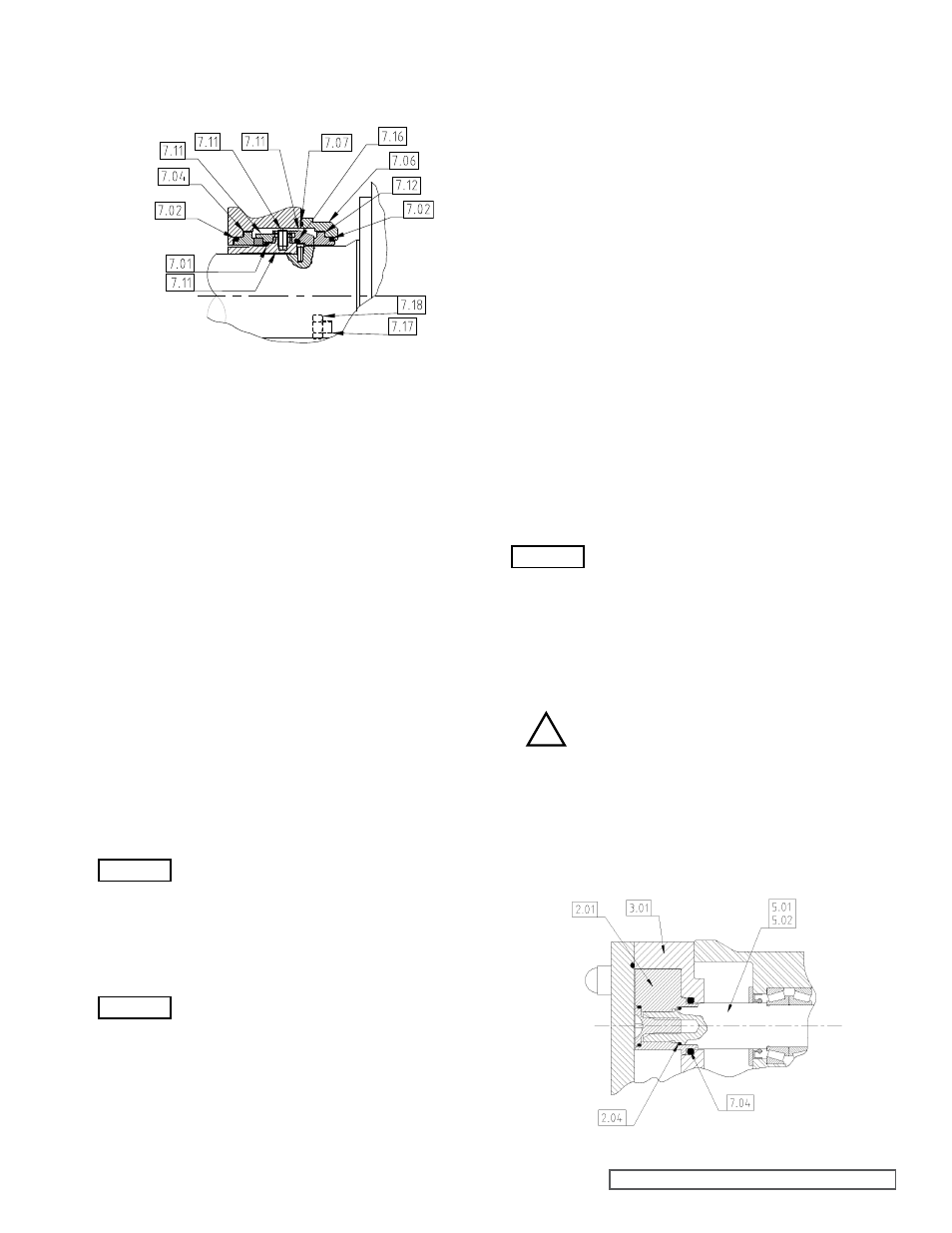

5.3.5 CP50 DOUbLE fLUSHED

MECHANICAL SEAL REMOVAL

- Remove head (1.01), rotor caps (2.02), O-rings (2.03),

retainers (2.05), rotors (2.01), Orings (2.04) and casing

(3.01), refer to sections 4.3.1 and 4.3.2.

- Remove rotary seal cartridge assemblies (7.11) with O-rings

(7.01) and (7.16) from shafts (5.01 and 5.02) by simply sliding

off. Do not loosen screws in rotary seal cartridge assemblies

(7.11).

- Remove housings (7.06) from shafts (5.01 and 5.02)

complete with stationary seal seats (7.04), O-rings (7.02)

and O-rings (7.07).

- Remove stationary seal seats (7.04), and O-rings (7.07) from

housings (7.06).

- Remove stationary seal seats (7.04) and O-rings (7.02) from

casing (3.01).

5.3.6 CP50 DOUbLE fLUSHED

MECHANICAL SEAL

REPLACEMENT

Refer to Figure 56.

- Install O-rings (7.02) to stationary seal seats (7.04).

- Install stationary seal seats (7.04) to casing (3.01) ensuring

correct location of O-rings (7.02).

Note: The stationary seal seat (7.04) has a

triangular shape, which must locate fully into

the casing (3.01), bore.

- Install O-rings (7.02) to stationary seal seat (7.04).

- Install stationary seal seats (7.04) to housings (7.06) ensuring

correct locations of O-rings (7.02) and stationary seal seats

(7.04) in housings (7.06).

Note: The stationary seal seat (7.04) has a

triangular shape, which must locate fully into

the housing (7.06), bore.

- Install housings (7.06) to shafts (5.01 and 5.02).

- Clean faces of outboard seal (7.11 and 7.04) use a soft tissue

and a suitable solvent based cleaner for best results.

- Install rotary seal cartridge assemblies (7.11) with O-ring (7.01)

and (7.16) to shafts (5.01 and 5.02) ensuring engagement

of drive slots with pins (5.23) in shafts (5.01 and 5.02).

- Install casing (3.01), O-rings (2.04), rotors (2.01), retainers

(2.05), O-rings (2.03), rotor caps (2.02) and head (1.01),

refer to section 4.3.5.

- Secure housings (7.06) to casing (3.01) with nuts (7.18).

6.0 CLASSIC+ SINGLE O-RING

SEALS

6.1 GENERAL PROCEDURES

fOR fITTING SINGLE O-RING

SEALS

“Quick Summary” of O-Ring seal installation.

- O-ring seals are a simple but effective means of shaft sealing.

They will provide optimum performance only if installed

carefully in accordance to the following instructions below

and sections 6.2 and 6.3.

- Remove any sharp corners and burrs that could damage

O-rings.

- Always inspect for wear, the diameter on the rotor where the

O-ring seal is located.

- Be sure that all seal component fitting bores, housings,

followers, sleeves etc. are thoroughly cleaned before

installation.

- All O-rings should be lightly lubricated with an appropriate

lubricant (suitable for application) before installation.

Note: Do not run an O-ring seal dry.

6.2 O-RING SEALS fOR CP10,

CP20, CP30 AND CP40 PUMPS

6.2.1 CP10, CP20, CP30 AND CP40

O-RING SEAL ASSEMbLy

AND REMOVAL

- Before assembly or disassembly of the seals,

ensure pump is fully shutdown, refer to section

3.5.

- Install O-ring (7.04) into the casing (3.01).

- Install O-ring (2.04) onto shaft (5.01 and 5.02).

Note: During installing of the rotors to shafts care must

be taken not to damage or unseat the O-ring seal when

inserting the rotor (2.01) into O-ring (7.04).

- To disassemble reverse the above procedure.

figure 56

Double flushed mechanical seal CP50

figure 57

O-Ring Seal for a CP10, CP20, CP30 and CP40

WARNING

!

WARNING

WARNING