Viking Pump TSM000: General Information User Manual

Viking Pump Pumps

SECTION TSM 000

PAGE

1 Of 8

ISSUE

I

VIKING PUMP, INC.

•

A Unit of IDEX Corporation

•

Cedar Falls, IA 50613 USA

TECHNICAL SERVICE MANUAL

CONTENTS

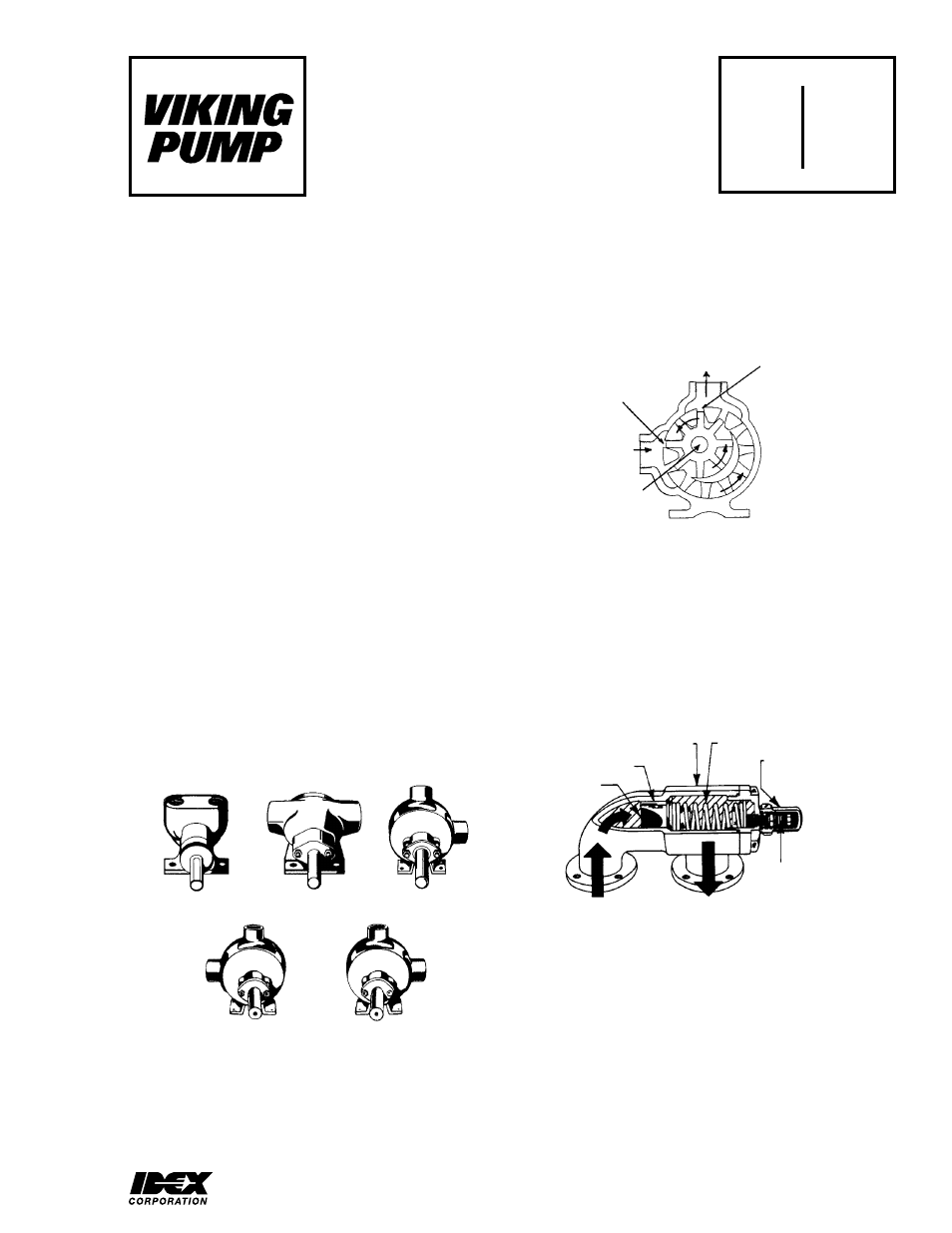

figurE 1

Installation, General Comments

1

Safety Information and Instructions

2

Foundation

3

Alignment

3

Piping

4

Start Up

5

Rapid Wear

6

Troubleshooting

6

Preventative Maintenance

7

Do’s and Don’ts

8

Before installation is started, a few items of a general nature should

be considered

1. Location - always locate the pump as close as possible to the

supply of liquid to be pumped Locate it below the liquid supply

if at all practical Viking pumps are self priming but the better the

suction conditions the better the performance

2. Accessibility - the pump should be located where it is accessible

for inspection, maintenance, and repair For large pumps, allow

room to remove the rotor and shaft without removing the pump

from the base

3. Port Arrangement - since the pumps have different port

arrangements depending on the model, port location should

be checked before starting the installation The ports may be

upright, opposite or at right angles to each other,

see figure

1. The right angle ports are normally right-hand, see figure

2; some models are available with left-hand arrangements; still

other models are available with the right angle ports located in

any one of eight positions including right-hand and left-hand

4. Suction/Discharge - shaft rotation will determine which port is

suction and which is discharge A look at

figure 3 will show

how rotation determines which port is which; as the pumping

elements (gears) come out of mesh, point

“A” on figure 3,

liquid is drawn into the suction port; as the gears come into

iNSTALLATiON

gENErAL COMMENTS

figurE 2

figurE 3

5. Pressure Protection - Viking pumps are positive displacement

This means that when the pump is rotated, liquid will be delivered

to the discharge side of the pump If there is no place for this

liquid to go - discharge line is blocked or closed - pressure can

build up until the motor stalls, the drive equipment fails, a pump

part breaks or ruptures, or the piping bursts Because of this,

some form of pressure protection must be used with a positive

displacement pump This may be a relief valve mounted directly

on the pump, an inline relief valve, a torque limiting device or a

rupture disk

figurE 4

CuTAwAy Of vikiNg iNTErNAL prESSurE rELiEf vALvE

CAp

SpriNg (A)

vALvE bOdy (C)

pOppET (b)

Liquid OuTLET

Liquid iNLET

pOiNT (E)

AdjuSTiNg

SCrEw (d)

(ShOuLd ALwAyS

pOiNT TOwArd

SuCTiON pOrT)

The pressure relief valve mounted on Viking pumps and most in-line

valves are of the spring loaded poppet design

See figure 4. The

spring

(A) holds poppet (b) against the seat in the valve body (C)

with a given force determined by the spring size and by how tightly

it is compressed by the adjusting screw

(d). The pump discharge

pressure pushes against the underside of the poppet at point

(E).

When the force exerted by the liquid under the poppet exceeds that

exerted by the spring, the poppet lifts and liquid starts to flow through

the valve As the discharge pressure builds up, more and more of

the liquid flows through until a pressure is reached at which all of the

liquid being pumped is going through the valve This pressure is the

relief valve setting

mesh, point

“b”, the liquid is forced out the discharge port

Reversing the rotation reverses the flow through the pump

When determining shaft rotation, always look from the shaft end

of the pump Unless otherwise specified, rotation is assumed to

be clockwise (CW), which makes the suction port on the right

side of the pump The idler pin, which is offset in the pump head,

should be properly positioned toward and an equal distance

between the port connections

Electronic copies of the most current TSM issue can be found on the Viking Pump website at www.vikingpump.com

diSChArgE

idLEr piN

SuCTiON

a

b

LEfT

hANd

puMp

righT

hANd

puMp

iNSTALLATiON, STArT up, TrOubLEShOOTiNg,

prEvENTATivE MAiNTENANCE, dO’S & dON’TS