Viking Pump TSM285: Classic+ Lobe Pump User Manual

Page 25

SECTION TSM 285

ISSUE

A

PAGE 25 OF 36

5.0 CLASSIC+ MECHANICAL SEAL

REMOVAL & REPLACEMENT

5.1 GENERAL PROCEDURES fOR

INSTALLING MECHANICAL

SEALS

“Quick summary” of mechanical seal installation

- Mechanical seals are precision-engineered assemblies

incorporating finely lapped seal faces and seats. They must

be handled with care and will not give optimum performance

unless installed carefully and according to instructions.

- When mechanical seals are to be reused, ensure seal

components are kept in their appropriate sets. Do not mix

old and new seal faces on the same seal.

- Remove any sharp corners and burrs that may damage any

elastomers such as O-rings or lipseals.

- Be sure that all seal component fitting bores and housings

are thoroughly cleaned before installation.

- The seal faces and seats must be handled with care and

cleaned thoroughly before installation.

- Be sure that seal faces are undamaged and the O-rings are

not cut, swollen or cracked.

- All O-rings should be lightly lubricated with a suitable

lubricant (silicon grease, soap etc.) before installation but

ensure there is no excessive amount of lubricant especially

around the seal face area.

- Ensure when installing seals with brittle faces and seats

such as silicon carbide that extra care is taken.

- Do not use any excessive force to install a mechanical

seal. If it is difficult to position and assemble the seal then

something is wrong.

- If you drop or damage a seal, do not install it before an

inspection has been carried out.

- Do not run a mechanical seal dry.

5.2 CP10, CP20, CP30 AND CP40

MECHANICAL SEALS

5.2.1 CP10, CP20, CP30 AND CP40

SINGLE MECHANICAL SEAL

REMOVAL

- Remove head (1.01), rotor retainers (2.02), O-rings (2.04)

and casing (3.01), refer to section 4.1.2.1 (CP10, CP20 and

CP30) or section 4.2.2.1 (CP40).

- Loosen but do not remove screws in rotary cartridge assembly

(7.05) which secure rotary seal cartridges to shafts (5.01 and

5.02).

- Remove rotary seal cartridges (7.05) with O-ring (7.02) from

shafts (5.01 and 5.02).

- Remove stationary seal seats (7.04) and O-rings (7.01) from

casing (3.01).

5.2.2 CP10, CP20, CP30 AND CP40

SINGLE MECHANICAL SEAL

REPLACEMENT

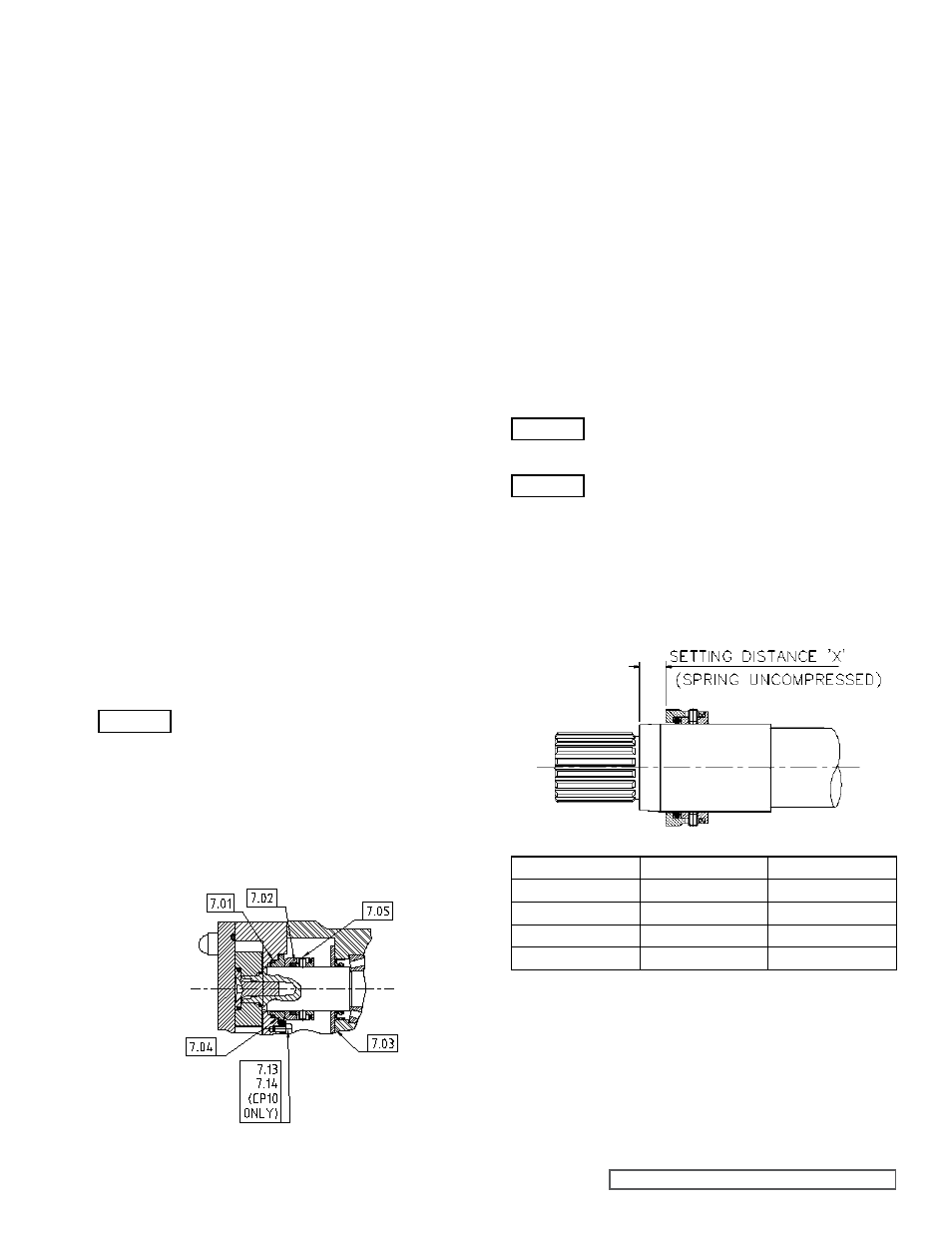

Refer to Figure 50 for CP10, CP20, CP30 and CP40

- Install O-rings (7.01) to stationary seal seat (7.04).

- Install stationary seal seats (7.04) to casing (3.01) ensuring

correct location of O-rings (7.01).

Note: On CP10 models the stationary seal

seat (7.04) has a location recess which fits

over the anti-rotation washer (7.13).

Note: On CP20, CP30 and CP40 models the

stationary seal seat (7.04) has a triangular

shape, which must locate fully into the casing

(3.01) bore.

- Install rotary seal cartridges (7.05) with O-ring (7.02) to

shafts (5.01 and 5.02) positioning to correct setting distance,

see Figure 50 and tighten screws (7.05) to correct torque,

refer to section 8.2.

- Install casing (3.01), O-rings (2.04), rotors (2.01), O-rings

(2.03), rotor retainers (2.02) and head (1.01), refer to sections

4.1.4 (CP10, CP20 and CP30) or 4.2.5 (CP40).

figure 49

Single Un-flushed Mechanical Seal

Pump Model

X (mm)

X (inches)

CP10

14.3

0.5630

CP20

10.8

0.4252

CP30

13.4

0.5276

CP40

17.5

0.6890

figure 50

Setting Distance for Seals

WARNING

WARNING

WARNING