Viking Pump TSM1470: HI-LO Double Pumps User Manual

Technical service manual, Contents introduction, Repair

VIKING PUMP, INC.

•

A Unit of IDEX Corporation

•

Cedar Falls, IA 50613 USA

VIKING PUMP, INC.

•

A Unit of IDEX Corporation

•

Cedar Falls, IA 50613 USA

TECHNICAL SERVICE MANUAL

SECTION TSM 1470

PAGE

1 Of 8

ISSUE

f

CONTENTS

INTRODUCTION

General

The following items must be considered prior to pump

installation:

1. Location - locate the pump as close as possible to the

supply of the liquid being pumped. If possible, locate

the pump below the liquid supply. Viking pumps are self

priming; but, the better the suction conditions, the better

the pump will perform.

2. Accessibility - the pump must be accessible for

inspection, maintenance and repair.

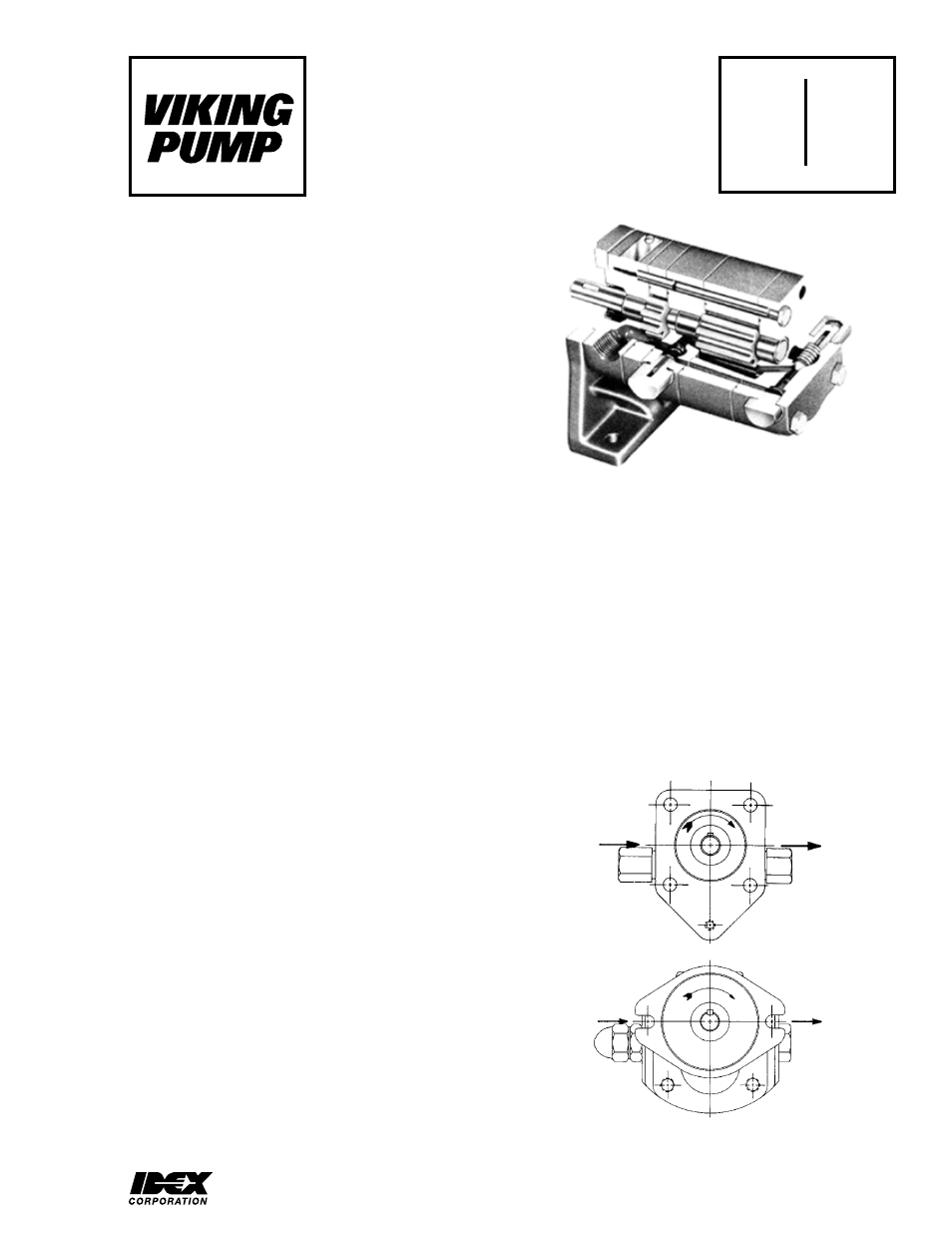

3. Suction/Discharge - Hi-Low Double pumps are

designed for clockwise rotation

only (viewed from shaft

end). Refer to Figure 1.

4. Pump Life - pump life is a factor of many parameters,

mainly pressure, speed and duty cycle. Temperature,

contamination and type of hydraulic oil also have a

definite effect.

5. Hydraulic Oil - Viking recommends using industrial

grade hydraulic oil. Temperature must not exceed 150

ºF for optimum life of hydraulic oil. Operating viscosity

must be between 100 and 300 SSU.

6. Filter / Strainer - on a hydraulic system, use a return

line filter with a maximum 10 micron rating to keep the

system clean and free of contaminating elements. A 100

mesh strainer is recommended in the suction line.

7. Pressure Relief Valve - a pressure relief device must

be installed in the system to provide over-pressure

protection. If a line is blocked or closed, pressure builds

up until the motor stalls, drive equipment fails, a pump

part breaks or piping bursts.

8. Discharge Line - select discharge piping, hoses and

fittings rated for maximum system pressure.

9. Storage - if the pump is to be stored, drain the pump and

apply a light coat of non-detergent SAE 30 weight oil to

all internal pump parts. Apply grease to the pump shaft

extension. Viking suggests rotating the pump shaft by

hand one complete revolution every 30 days to circulate

the oil.

S

D

FIGURE 1

S

D

Introduction . . . . . . . . . . . . . . . . . . . . . . .

1

Repair . . . . . . . . . . . . . . . . . . . . . . . . . .

1

Safety Information. . . . . . . . . . . . . . . . . . . .

2

Installation. . . . . . . . . . . . . . . . . . . . . . . .

3

Start Up . . . . . . . . . . . . . . . . . . . . . . . . .

4

Troubleshooting . . . . . . . . . . . . . . . . . . . . .

4

Miscellaneous. . . . . . . . . . . . . . . . . . . . . .

5

Do’s and Don’ts . . . . . . . . . . . . . . . . . . . . .

6

REPAIR

1. Parts For A Preventative Maintenance Program -

- Mechanical Seal or Lipseal(s) (Not applicable for Mag

Drive pumps)

- O-rings

2. Parts For A Major Overhaul - The Viking Spur Gear

series pumps have very tight clearances and precision

machining tolerances, and wear on any of the parts will

typically indicate that most of the critical parts are worn.

Therefore, if wear is found on any of the pump parts,

Viking recommends replacing the entire pump. Always

supply the serial number from your pump nameplate

when requesting a replacement.

FIGURE 2

GP-05 HI-LO

DOUbLE PUMP

INSTALLATION, START UP, TROUbLESHOOTING,

PREVENTIVE MAINTENANCE, DO’S & DON’TS

GP-04, GP-05 & GP-07 HI-LO DOUbLE PUMPS

Electronic copies of the most current TSM issue can be found on the Viking Pump website at www.vikingpump.com