3 cp50 gearbox disassembly – Viking Pump TSM285: Classic+ Lobe Pump User Manual

Page 22

SECTION TSM 285

ISSUE

A

PAGE 22 OF 36

- Remove screws (6.11) and gearbox cover (6.00). The

gearbox cover (6.00) is located on dowels (6.06) and sealed

with suitable liquid sealant.

- Remove oil seal (6.03) from gearbox cover (6.00).

- Loosen by two full turns all screws in retainer (5.16) on the

lay shaft (5.02). Once this is done the retainer may release

its grip. If it does not become free identify and remove the

three screws which differ in color (these may also have a

washer under the head). Once these screws are removed

tapped holes will be revealed. Insert three jackscrews (M10

x 40 setscrews), into the tapped holes and tighten until the

retainer’s grip is broken. Remove the retainer.

- Remove lock nut (5.12) and tab washer (5.11), then remove

timing gears (5.09), gear key (5.10), spacer (5.18), O-ring

(5.22) and lipseal (83).

4.3.3 CP50 GEARbOX

DISASSEMbLy

(After completing 4.3.1 and 4.3.2)

Before proceeding with disassembly of the gearbox remove

product seals; refer to section 5.3 for Mechanical Seals and

6.3 for O-ring Seals.

The following procedure describes complete disassembly of

the gearbox, refer to Figure 44.

- Remove guard (4.06) and shaft slingers (7.03) if fitted.

- Remove drive key (6.12).

- Remove oil drain plugs (6.09) and breather plugs (6.10),

drain oil into suitable container and retain (inspection may

later be required).

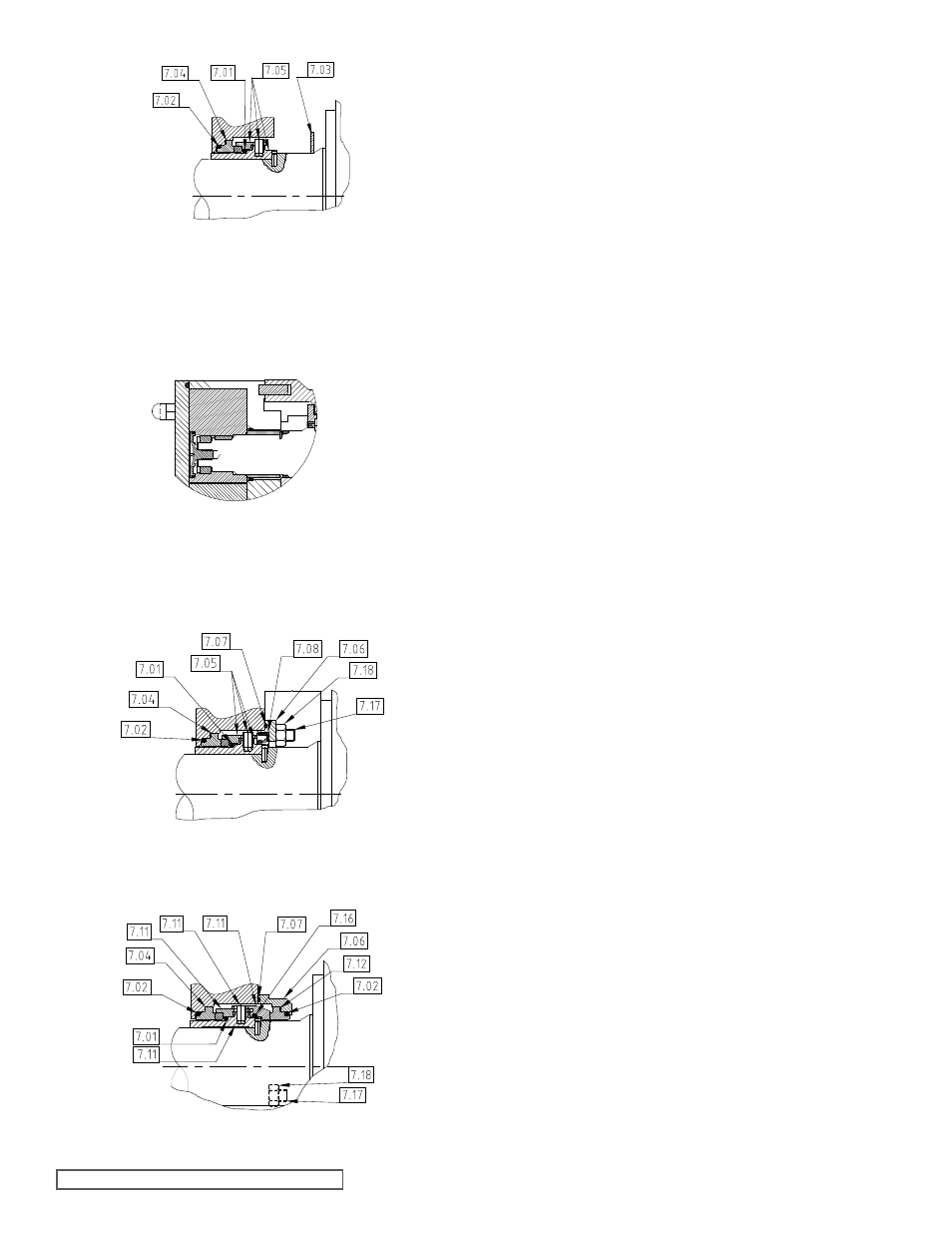

figure 42

Single flushed Mechanical Seal for CP50

figure 43

Double flushed Mechanical Seal for CP50

figure 40

Single Un-flushed Mechanical Seal – CP50

figure 41

Single O-ring Seal CP50