06 system operation, 06 system operation -8, A. operational suggestions – Tweco 3000 Merlin User Manual

Page 40: B. using corner slowdown for mechanized cutting, C. setting csd output, D. drag mode feature, Figure 4-7 corner slowdown (csd) adjustment

OPERATION

4-8

Manual 0-2532

4.06 System Operation

NOTE

Frequently review the safety precautions at

the front of this manual.

This section contains operating information which is spe-

cific to the power supply. Detailed operating information

for torches can be found in the appropriate Torch

Instruc-

tion Manual.

WARNINGS

Disconnect primary power at the source be-

fore assembling or disassembling power sup-

ply, torch parts, or torch and leads assemblies,

or adding coolant.

It is not enough to simply move the ON/OFF

switch on the unit to OFF position when cut-

ting operations have been completed. Always

open the power supply disconnect switch five

minutes after the last cut is made.

A. Operational Suggestions

The suggestions below should be followed in all cutting

and gouging operations:

1. Wait five minutes before setting the ON/OFF switch

to OFF after operation. This allows the cooling fan to

run to dissipate operating heat from the power sup-

ply.

2. For maximum parts life, do not operate the pilot arc

any longer than necessary.

3. Use care in handling torch leads and protect them

from damage.

4. In continuous cutting applications using CO2, it is of-

ten necessary to manifold four to six cylinders together

to maintain adequate flow at operating pressures.

B. Using Corner Slowdown for Mechanized

Cutting

The corner slowdown (CSD) function provides a re-

duction in output current which corresponds with the

reduced travel speed of a mechanized torch as it

changes direction at a sharp corner. When activated

(by CNC or other control device) corner slowdown

eliminates excessive metal removal in corners.

Normally open (NO) contacts (supplied by the con-

trol device) close when the torch travel speed de-

creases through a corner. When the contacts close,

power supply output drops to a preset current level.

C. Setting CSD Output

NOTE

Corner Slowdown (CSD) is set at the RC6010

Remote Control.

OUTPUT AMPS

PLASMA

ENABLE

ON

START

REMOTE POWER SUPPLY CONTROL

CSD

(%)

0

25

75

100

50

TRAVEL

SPEED

125+

IPM

0-125

IPM

RUN

PURGE

SET

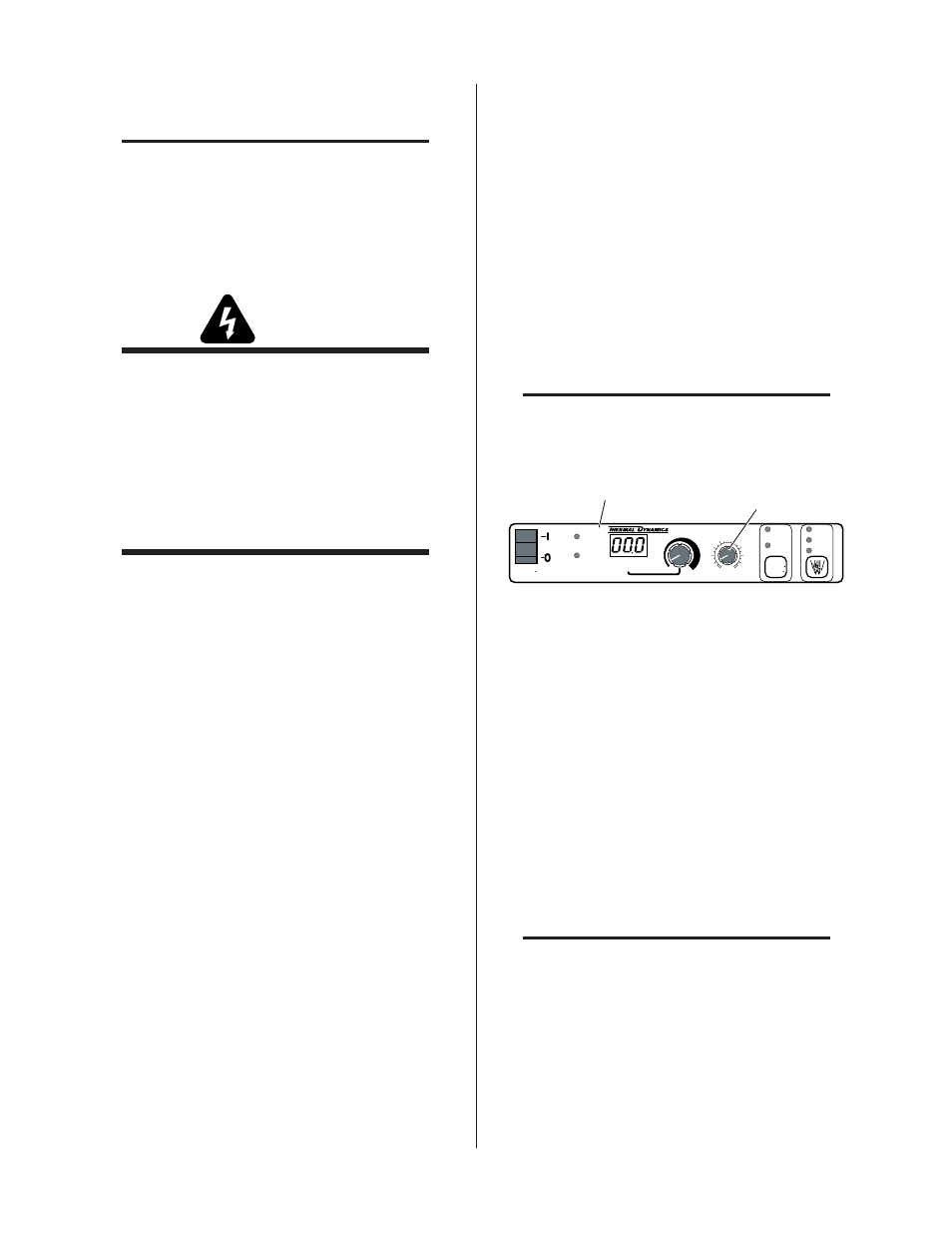

Front Panel of

RC6010 Remote Control

CSD (%)

Adjustment

A-00997

Figure 4-7 Corner Slowdown (CSD) Adjustment

The corner slowdown adjustment is located on the front

panel of the RC6010 Remote Control. The control sets

corner slowdown output to any current level from the

minimum (50 amps) to the maximum (150 amps) level

of the system. The corner slowdown output level is a

percentage of the main output level. Typically the CSD

output level should not be set lower than 70% of the main

current level to insure full arc penetration during corner

slowdown.

If the cutting machine controller activates CSD (three

decimals on the display) during pierce starts it may not

be desirable to set CSD below 100% as starting current

will be reduced requiring longer pierce times.

NOTE

For electrical connections, refer to Appendix

VI, CNC Interface Schematic

D. Drag Mode Feature

Should the torch tip contacts the workpiece the out-

put current will immediately drop to between 40 to

50 amps to minimize potential tip damage.