09 work cable and ground connections, 09 work cable and ground connections -5 – Tweco 3000 Merlin User Manual

Page 23

Manual 0-2532

3-5

INSTALLATION

Input Voltage

Terminal Board

L1

L2

L3

Primary Power

Cable

Strain Relief

Fitting

Ground

Connection

Busbars

A-00893

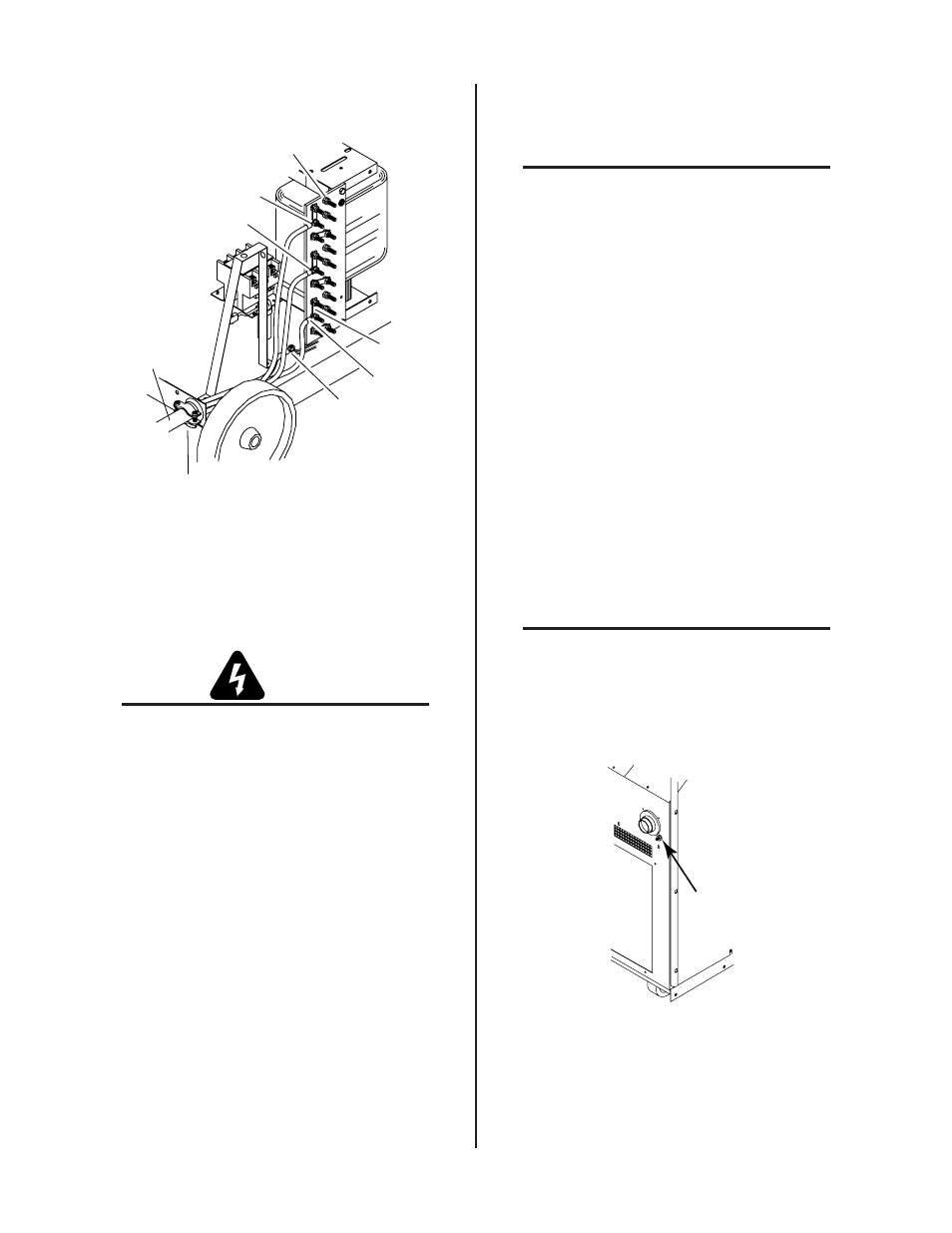

Figure 3-6 Input Voltage Connections

2. Connect the electrical ground wire to the ground

lug on the base of the unit.

WARNING

The electrical ground wire must be connected

to the ground lug in the base of the unit for

proper grounding.

3. Connect the three line leads to the input voltage

terminal board per the following:

• Line 1 to terminal L1.

• Line 2 to terminal L2.

• Line 3 to terminal L3.

4. Tighten all nuts.

3.09 Work Cable And Ground

Connections

NOTE

Refer to Appendix III for a block diagram of a

typical mechanized system work and ground

cable connections.

A. Electromagnetic Interference (EMI)

Pilot arc initiation generates a certain amount of electro-

magnetic interference (EMI), commonly called RF noise.

This RF noise may interfere with other electronic equip-

ment such as CNC controllers, remote controls, height

controllers, etc. To minimize RF interference, follow these

grounding procedures when installing mechanized sys-

tems:

B. Grounding

1. The preferred grounding arrangement is a single point

or “Star” ground. The single point, usually on the cut-

ting table, is connected with 1/0 AWG (European 50

mm

2

) or larger wire to a good earth ground (refer to

paragraph ‘C’, Creating An Earth Ground). The ground

rod must be placed as close as possible to the cutting

table, ideally less than 10 ft (3.0 m), but no more than

20 ft (6.1 m).

NOTE

All ground wires should be as short as pos-

sible. Long wires will have increased resis-

tance to RF frequencies. Smaller diameter

wire has increased resistance to RF frequen-

cies, so using a larger diameter wire is better.

A-00986

Grounding

Stud

Figure 3-7 Power Supply Earth Grounding Stud

Location