Section 4: operation, 01 introduction, 02 functional overview – Tweco 3000 Merlin User Manual

Page 33: 03 front and rear panel descriptions, Section 4, Operation -1

Manual 0-2532

4-1

OPERATION

SECTION 4:

OPERATION

4.01 Introduction

This Section provides a description of the Power Supply

operating controls and procedures. Identification of the

Front and Rear Panel Controls is followed by operating

procedures.

4.02 Functional Overview

The system is a high performance plasma cutting sys-

tem which can cut most metals from gauge thickness up

to two inches. With a quick change of torch parts, power

supply can also be used for plasma arc gouging.

In its simplest form, a system consists of one Power Sup-

ply, one Arc Starter Box and one Maximizer 300 Liquid

Cooled Torch and leads connected.

4.03 Front and Rear Panel

Descriptions

This sub-section provides specific functional descriptions

of the Power Supply front and rear panel operating con-

trols, indicators and connections. The Power Supply has

three main front panels and one rear panel. Each panel

is described in this sub-section as to the functions of the

connections, switches, and indicators.

A-00987

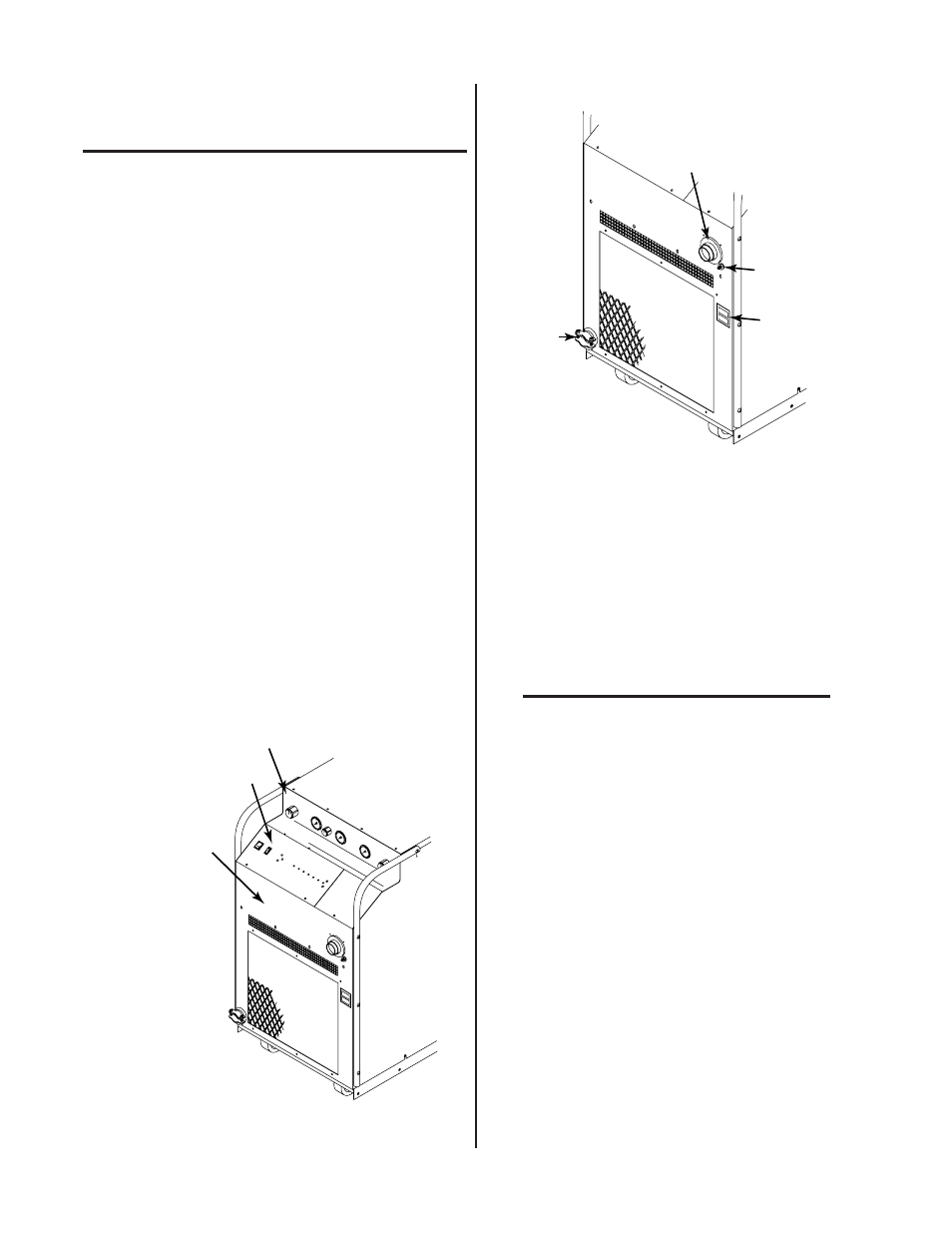

Control Front Panel

Gauge Front Panel

Lower Front Panel

Figure 4-1 Main Front Panels

A. Lower Front Panel

A-00996

1

2

3

4

Figure 4-2 Lower Front Panel

1. Work Cable Strain Relief

Strain relief to secure the factory installed work cable

and clamp to the Power Supply.

2. Grounding Stud

Grounding stud supplied for grounding the system to

a good earth ground.

3. Torch Leads Boot

NOTE

The Torch cannot be connected directly to the

TORCH connector as the HF is generated in

the Arc Starter Box.

Connection for the Torch Leads Extension Assem-

bly. The connector supplies all the required signals,

gases, and coolant to the torch control box.

4. Optional Meters

a. Upper Meter - Hour

The upper meter indicates the total number of

hours that the main cutting arc has been on. The

meter can not be reset and displays a maximum

of 999999 hours.

b. Lower Meter - Counter

The lower meter counts the number of times that

the cutting arc has been started. The meter can

not be reset and displays a maximum of 999999

starts.