12 external cable connections, 12 external cable connections -12, A. optional rc 6010 remote control – Tweco 3000 Merlin User Manual

Page 30: B. computer control interface (cnc)

INSTALLATION

3-12

Manual 0-2532

3.12 External Cable Connections

Depending on the options installed there are various

cables to be connected the Power Supply.

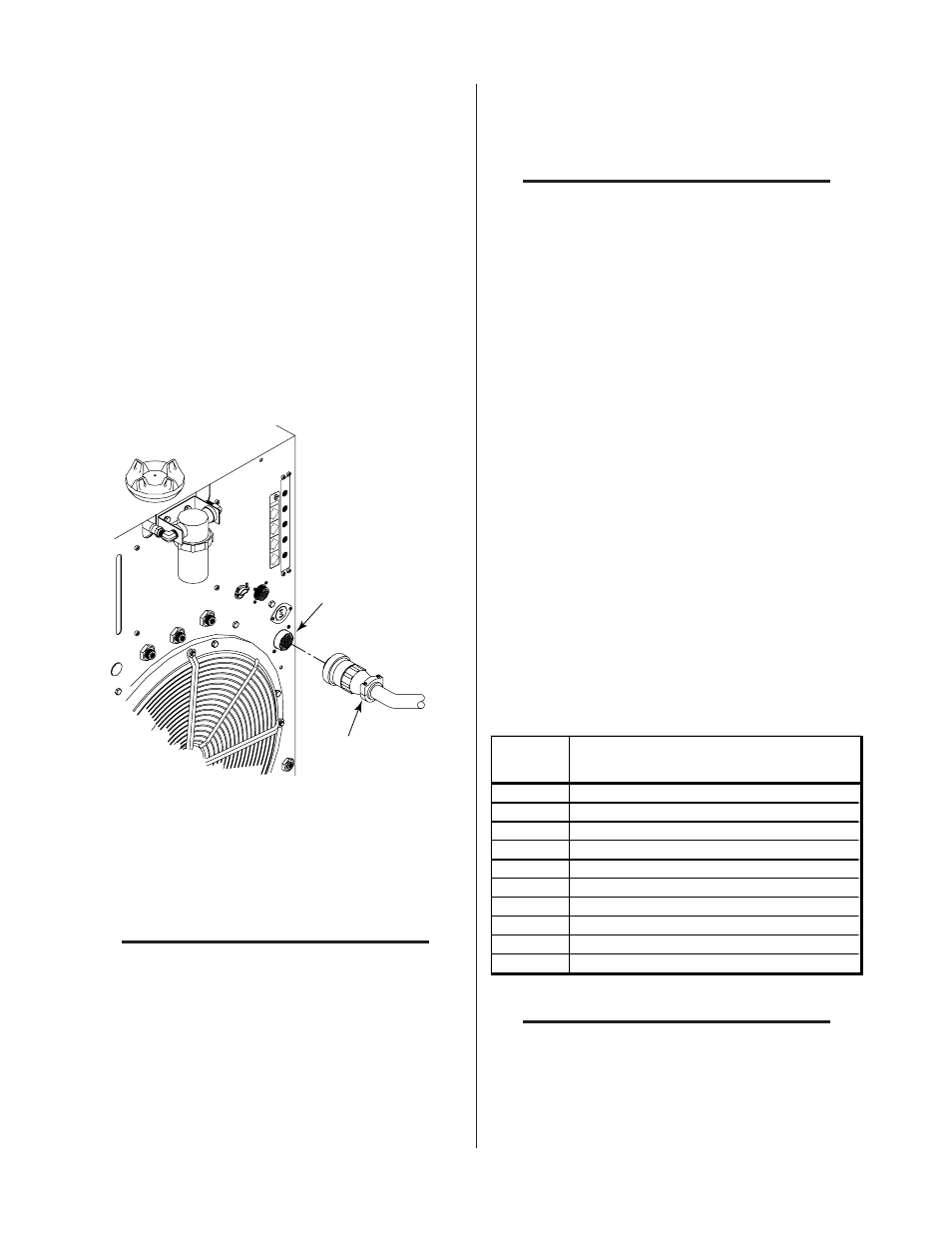

A. Optional RC 6010 Remote Control

For mechanized systems, the optional RC 6010 Remote

Control allows the operator to control all system func-

tions from a remote location. The control cable to inter-

face the RC 6010 to the Power Supply is available in

various lengths (Refer to Section 6.04, Options and Ac-

cessories).

1. Connect the control cable to the receptacle

marked REMOTE CONTROL (J15) on the rear

panel of the Power Supply.

OUTPUT

TO

CONTROL

MODULE

AIR

PLASMA

INPUT

N

2

PLASMA

INPUT

O

2

PLASMA

INPUT

PLASMA GAS

Ar/H

Ar/H

2

PLASMA

INPUT

A-01004

Cable From

Remote Control

REMOTE CONTROL

Connector (J15)

Figure 3-17 Remote Control Interface Connection

2. Connect the other end of the control cable to the

receptacle marked PS (J37) on the rear panel of

the remote control.

NOTE

Refer to the RC 6010 Remote Control Instruc-

tion Manual 0-2478 for more information on

the RC6010 Remote Control including CNC.

B. Computer Control Interface (CNC)

The computer control interface allows a mechanized sys-

tem to interface with a computer or other control device.

NOTE

Refer to Section 4.03-D for more information

on the CNC connections.

CNC cables can be interfaced to the Power Supply using

one of the following methods:

• Connector (J15) at the rear of the Power Supply

• Internal terminal strip in the Power Supply

Depending on the equipment ordered and the cables sup-

plied connect the CNC cable per one of the following:

1. Using supplied CNC cable

Connect the supplied Power Supply/CNC Cable

to the Power Supply rear connector J15 labelled

REMOTE CONTROL.

2. Using customer supplied CNC Cable

a. Remove the Left Side Panel from the Power

Supply as viewed from the front of the unit.

b. Locate the internal terminal strip (TB2) near

the heatsink.

c. Feed the CNC cable through the small strain

relief at the rear of the Power Supply.

d. Connect the CNC cable to the terminal strip

(TB) per the following chart:

TB

Connection

Description

1

One Side of Enable Signal

2

Other Side of Enable Signal

3

One Side of START(Low)/STOP (High) Signal

4

Other Side of START (Low)/STOP (High) Signal

5

Not Used

6

Not Used

7

One Side of Pilot Sensing Relay (PSR)

8

Other Side of Pilot Sensing Relay (PSR)

9

One Side of OK-To-Move Signal

10

Other Side of OK-To-Move Signal

NOTES

Connections to TB positions 1 through 8 are

activated with a switch or contact closure.

If Remote Control is not used the Enable Sig-

nal circuit must be closed.