B. control front panel, C. gauge front panel, Figure 4-3 front control panel – Tweco 3000 Merlin User Manual

Page 34

OPERATION

4-2

Manual 0-2532

B. Control Front Panel

NOTE

This hinged panel is the access cover to the

Logic Control PC Board.

1. ON/OFF Switch

ON position activates all system control circuits when

remote or CNC enable is ON.

OFF position deactivates control circuits.

2. RUN/SET/PURGE Switch

RUN position is used for torch operation.

SET position is used for setting gas pressures.

PURGE position is for purging the plasma gas line.

3. Current Control

Selects output current from 50 to 150 amps for ap-

plications on various materials and thicknesses. Cur-

rent control is disabled when Remote Control is used.

4. AC Power Indicator

Green light indicates AC power is being supplied to

the system when the ON/OFF switch is in ON posi-

tion.

OFF

ON

RUN

PURGE

SET

A-00887

AMPS

50

75

150

125

100

AC

TEMP

GAS

PRES.

COOLANT

COND.

DC

PILOT

1

2

3

4

5

6

7

8

9

10

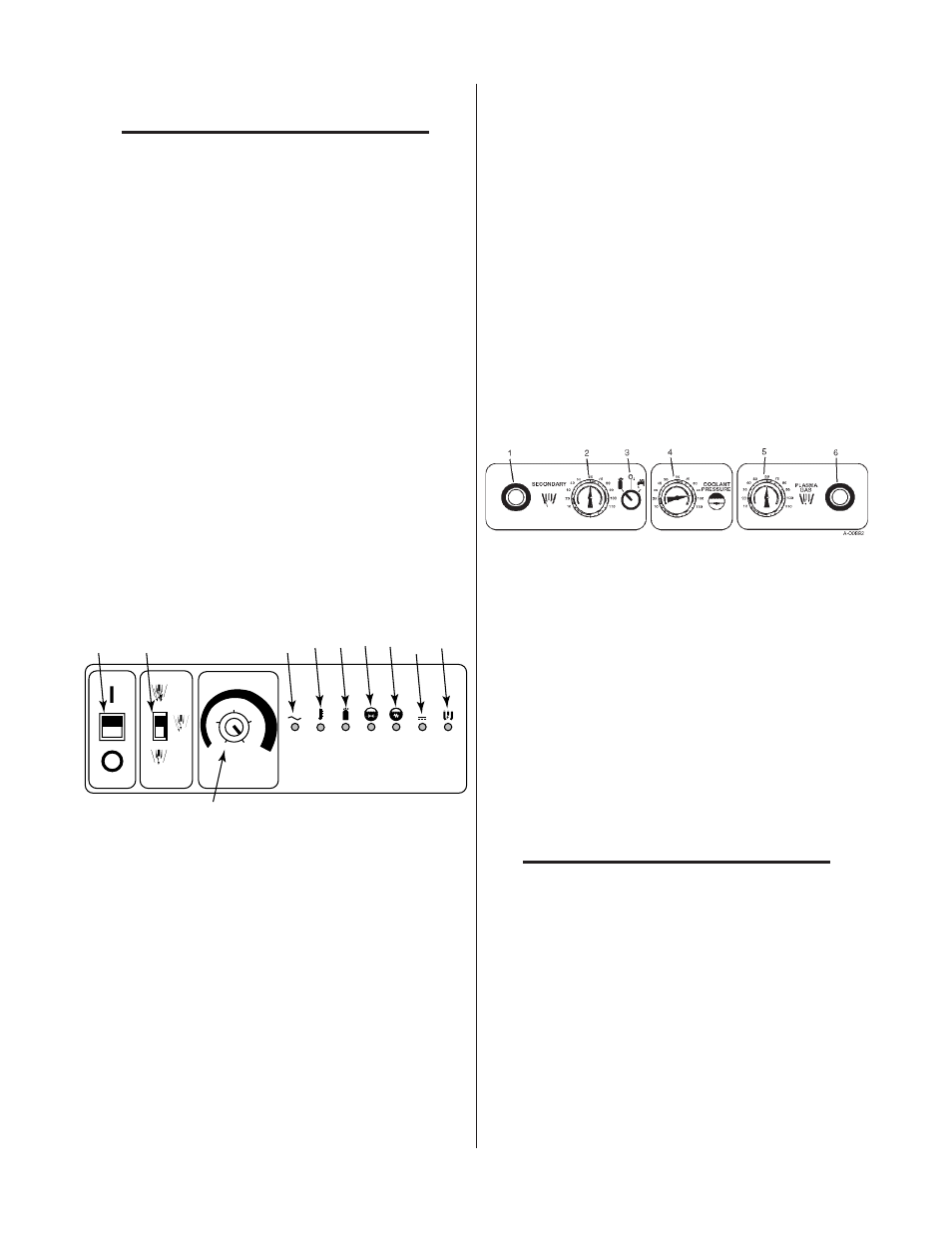

Figure 4-3 Front Control Panel

5. TEMP Indicator

Green light indicates proper operating temperature.

Red light indicates overheating. Unit must be allowed

to cool.

6. GAS Indicator

In SET position, yellow light in SET mode indicates

gas pressure switches are satisfied when gas is flow-

ing to the torch. Light goes out in PURGE or RUN

mode.

7. Coolant Pressure Indicator

Yellow light indicates adequate coolant flow.

8. Coolant Conductivity Indicator

Yellow light indicates proper coolant conductivity.

Light out indicates excessive coolant conductivity (re-

sistivity less than 0.1 MW). Replace coolant and de-

ionizer cartridge.

9. DC Indicator

Yellow light indicates main contactor closure supply-

ing voltage to the power supply output and cutting

current is available. Start signal must be applied.

10. PILOT Indicator

Yellow light indicates pilot arc contactor closure. Light

goes out when cutting arc is established and comes

back on if cutting arc is interrupted. Refer to Section

4.07-A and -B, Auto Restart Function.

C. Gauge Front Panel

Figure 4-4 Merlin 3000 Upper Gauge Panel

1. Secondary Pressure Control

Adjusts secondary gas pressure. Pull knob out and

turn clockwise to increase secondary pressure to de-

sired level.

2. Secondary Pressure Gauge

Displays secondary pressure from 0 - 100 psi (0 - 6.9

bar).

3. Secondary Mode Selector

Selects secondary mode to gas, oxygen (no second-

ary), or water.

NOTE

This switch must be in the gas (cylinder sym-

bol) mode for all secondary gases when the

Gas Control Option is installed.

4. Coolant Pressure Gauge

Displays coolant pressure from 0 - 160 psi (0 - 11.0

bar).

5. Plasma Pressure Gauge

Displays plasma gas pressure from 0 - 100 psi

(0 - 6.9 bar).