Powers 595 Series 11 Self-Operating Temperature Regulators - Type CD Composition Disc User Manual

Page 3

3

Caution:

Do not exceed maxi-

mum pressure differentials for

given valve sizes. The maximum

differential is the pressure the

valve has against it at shutoff. Too

large a differential can cause valve

chatter and/or prevent shutoff.

Sizing and Selection

■

Proper sizing of the Regulator is essential for correct system

operation. An undersized regulator will not allow suffi cient fl ow

at maximum load. An oversized regulator may cycle and will not

utilize the full valve stroke for effi cient modulation of fl ow. This

results in poor control and shortened valve life (quicker deterio-

ration of valve disc and seat). For these resasons, the correct

sizing of the regulator for actual expected conditions is consid-

ered essential for good control.

NOTE: Select a bulb (see page 12) that has the desired set point

in the upper third of the temperature range for best valve perfor-

mance.

Size the #11 Regulator for actual rather than maximum condi-

tions. Do not size according to pipe size; piping systems are

designed for different criteria than process controls. Refer to

Powers Form #AE-1, Valve Selection and Sizing for further rec-

ommendations.

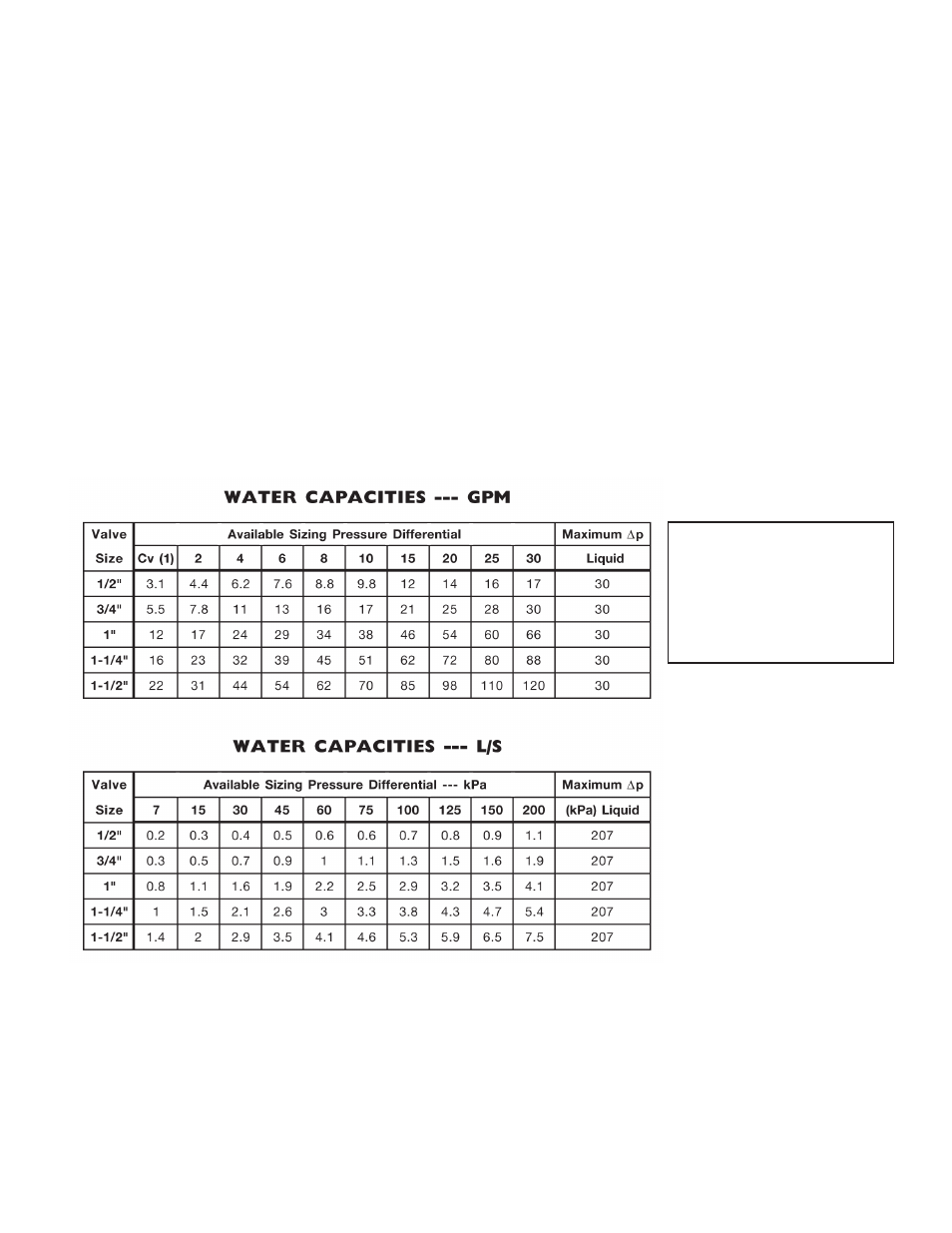

Maximum Operating Pressure Differential (differential for fl uid

fl ow): In order for the process medium to fl ow, a pressure drop

must exist across the valve. “Pressure differential” is the differ-

ence in valve pressure between the inlet and outlet under fl ow

conditions. The greater the differential, the greater the fl ow at

any given plug position.

Though the regulator should be sized for actual conditions, you

need to know the available differential at maximum fl ow. For

optimum control, take as much differential as possible across

the valve.

Water Capacities

■

Use a pressure drop of at least 25% of inlet pressure when sizing valves for water applications.