Joining the wing panels – E-flite Advance 25e User Manual

Page 9

9

E-flite Advance 25e ARF Assembly Manual

Drawing not to scale

Attach clevis

to outer hole

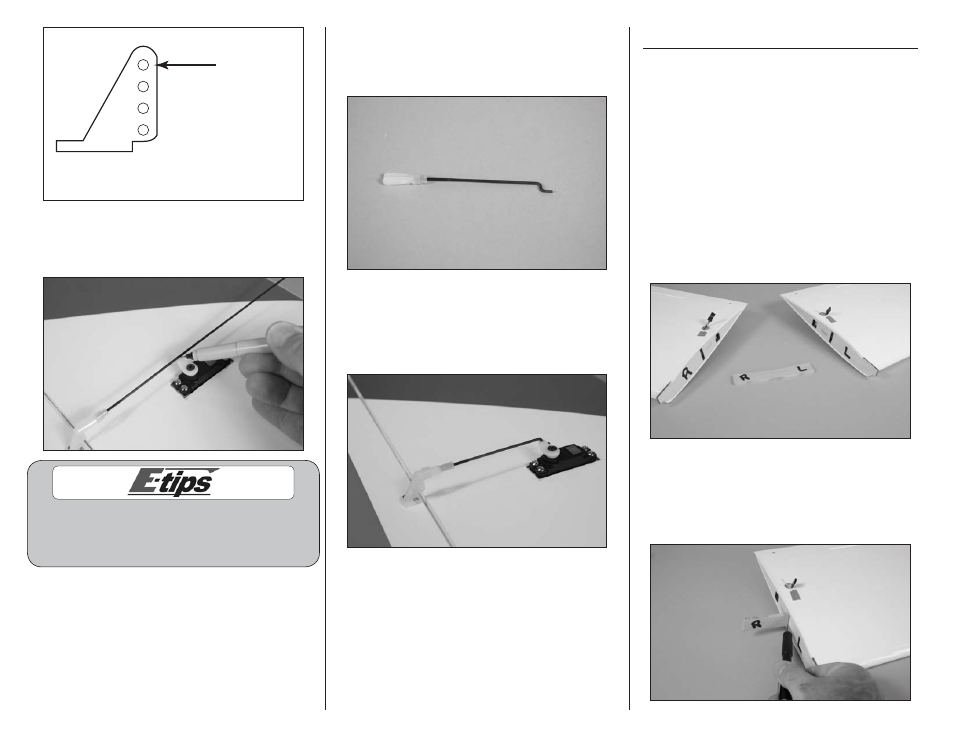

16. Use a felt-tipped pen to mark the pushrod

where it crosses the hole in the servo horn that was

enlarged in Step 6.

Making a Z-bend takes some skill. There is

plenty of excess wire to experiment with. We

recommend using Z-bend pliers (HAN119) to

make the perfect Z-bend in your pushrod wire.

17. Disconnect the clevis from the control horn.

Make a Z-bend in the pushrod wire using a pair

of pliers. Use side cutters to trim the excess wire to

match the photo below.

18. Insert the bend in the hole of the servo

horn. Reconnect the clevis to the outer hole of

the control horn. Slide the silicone tube over

the forks of the clevis to prevent it from opening

accidentally in flight.

19. Repeat Steps 1 through 19 to install the

remaining aileron servo and linkage. Remove the

low-tack tape securing the aileron before joining the

wing panels.

Joining the Wing panels

Required parts

Wing panel with aileron (left and right)

Hardwood wing joiner

Required Tools and Adhesives

30-minute epoxy

Pencil

Low-tack tape

Paper towel

Mixing stick

Mixing cup

Epoxy brush

Rubbing alcohol

Medium grit sandpaper

1. Locate the hardwood wing joiner. Mark the joiner

and wing panels with an “R” and “L” so the joiner

can be associated with a particular wing panel for

test fitting.

2. Slide the wing joiner into one of the wing panels.

Use a pencil to draw a line on the joiner against the

wing as shown. The joiner should easily slide into

the wing panel. If not, use medium grit sandpaper

to lightly sand the joiner so it slides in easily.