System introduction, 3 control reliability, 4 ez-screen grid operating features – Banner EZ-SCREEN Safety Light Curtain Systems User Manual

Page 8: Receiver emitter, Ez-screen grid

page

8

Banner Engineering Corp.

•

Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

System Introduction

EZ-SCREEN Grid

Instruction Manual

1.3 Control Reliability

In addition to physical location requirements, safety standards require a safety

system such as the EZ-SCREEN Grid to fulfill some internal requirements. For

example, for an optical safety system to be used in a Safety Category 4

application (per ISO 13849-1/EN954-1), it must be third-party certified to the

type 4 requirements of IEC 61496-1 and -2.

EZ-SCREEN Grid’s microprocessor-based circuitry features a “diverse-redundant”

design, in which two microprocessors of different design, running from different

instruction sets, constantly check all system components, including each other.

In addition, EZ-SCREEN Grid is extensively FMEA (Failure Mode and Effects

Analysis) tested to establish an extremely high probability that no system

component will ever (even if it does fail) cause a failure to danger.

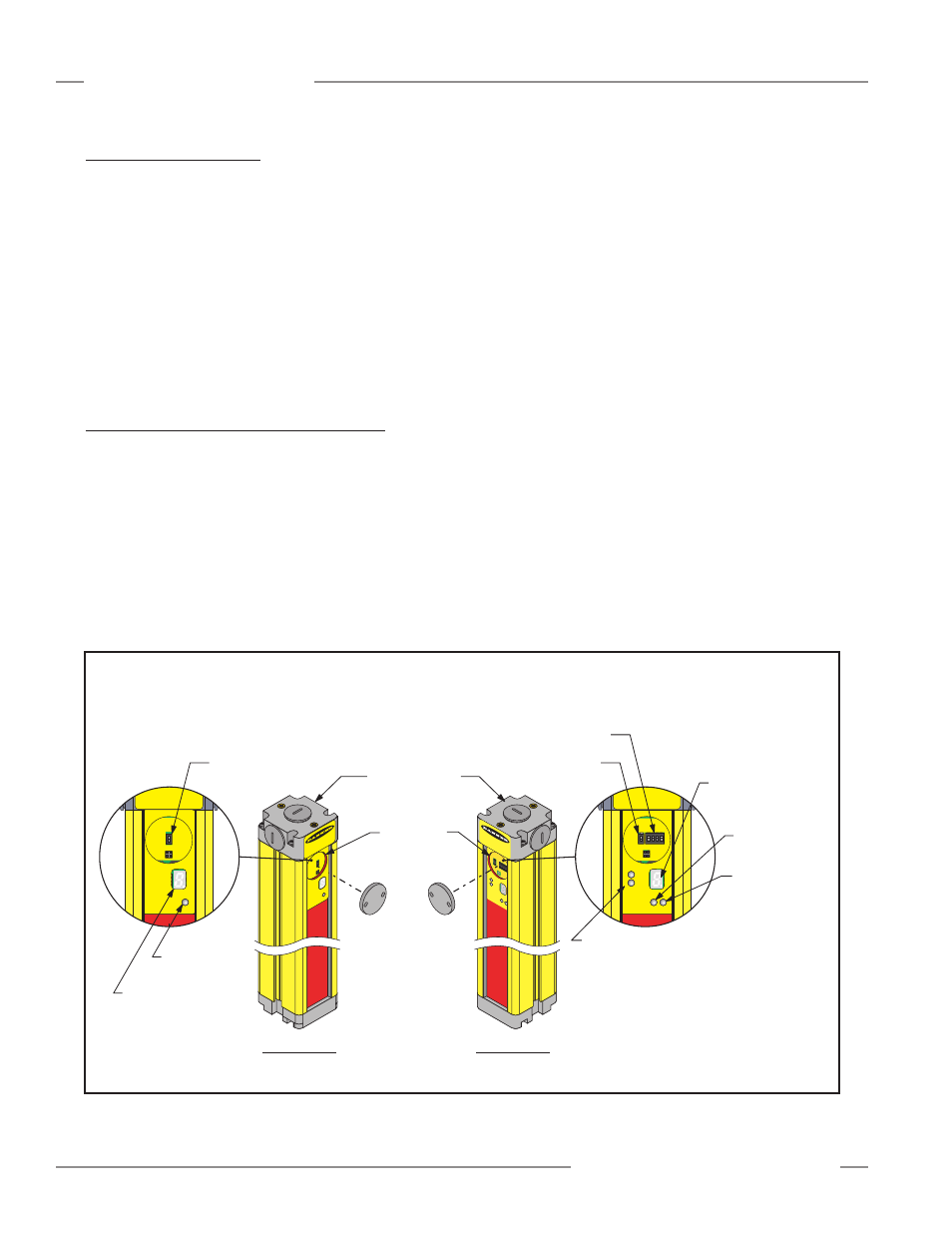

1.4 EZ-SCREEN Grid Operating Features

The Banner EZ-SCREEN Grid System features several selectable functions: trip or

latch output, external device monitoring (EDM), and scan code setting. These

settings are configured within the sensors, behind the threaded access port on

the front of each sensor and in the sensor wiring configuration; see Section 4.1

for more information.

Selectable Trip/Latch Output

The setting for latch or trip output also determines whether the System will enter

Run mode automatically or require a manual reset (see Section 4.1). If the

system is set for trip output, other measures must be taken to prevent a pass-

through hazard; see Section 3.3.2 for more information.

BE

AM

S

1

2

R

E

S

E

T

S

T

A

T

U

S

SC

AN

CO

DE

2

1

BEAMS

1

2

R

E

S

E

T

S

T

A

T

U

S

EZ-SCREEN Grid

BANNER ENGINEERING CORP., USA

888.373.6767

STATUS

SCAN

CODE

2

1

1

1

ON

2

3

4

SC

AN

CO

DE

2

1

T

L

1

2

T

L

1

E

D

M

E

D

M

2

S

T

A

T

U

S

BE

AM

S

1

2

R

E

S

E

T

S

T

A

T

U

S

EZ

-SC

RE

EN

Gri

d

BA

NN

ER

EN

GI

NE

ER

ING

CO

RP

., US

A

888

.37

3.6

767

E

D

M

E

D

M

2

T 1 T 1

1

L 2 L 2

SCAN

CODE

BEAMS

1

2

R

E

S

E

T

S

T

A

T

U

S

EZ-SCREEN Grid

BANNER ENGINEERING CORP., USA

888.373.6767

Receiver

Emitter

ST

ATUS

EZ

-S

CRE

EN

G

rid

BA

NN

ER

E

NG

IN

EE

RIN

G

CO

RP

., US

A

88

8.3

73

.67

67

Scan Code

Select Switch

Scan Code

Select Switch

Beam Status Indicators

(One for Each Beam) –

Bi-color Red/Green

Trip/Latch and EDM

Select DIP Switches

7-Segment

Diagnostic Display

7-Segment

Diagnostic Display

Reset Indicator –

Yellow

Status Indicator –

Bi-color Red/Green

Status Indicator –

Bi-color Red/Green

Wiring Chamber

End Cap

Configuration

Access Port

Figure 1-5. EZ-SCREEN features