Installation and alignment, 4 mechanical mounting procedure – Banner EZ-SCREEN Safety Light Curtain Systems User Manual

Page 26

page

26

Installation and Alignment

EZ-SCREEN Grid

Instruction Manual

3.4 Mechanical Mounting Procedure

Short-range emitters and receivers may be mounted up to 20 m (65') apart.

Long-range emitters and receivers may be mounted between 15 m (49') and

70 m (230') apart. If Banner SSM corner mirrors are used, the total range

decreases by approximately 8 percent per mirror, as follows:

Corner

Mirrors

Short-Range

Systems

Long-Range

Systems

1

18.3 m (60') total

64 m (210') total

2

16.8 m (55') total

59.5 m (195') total

3

15.2 m (50') total

55 m (180') total

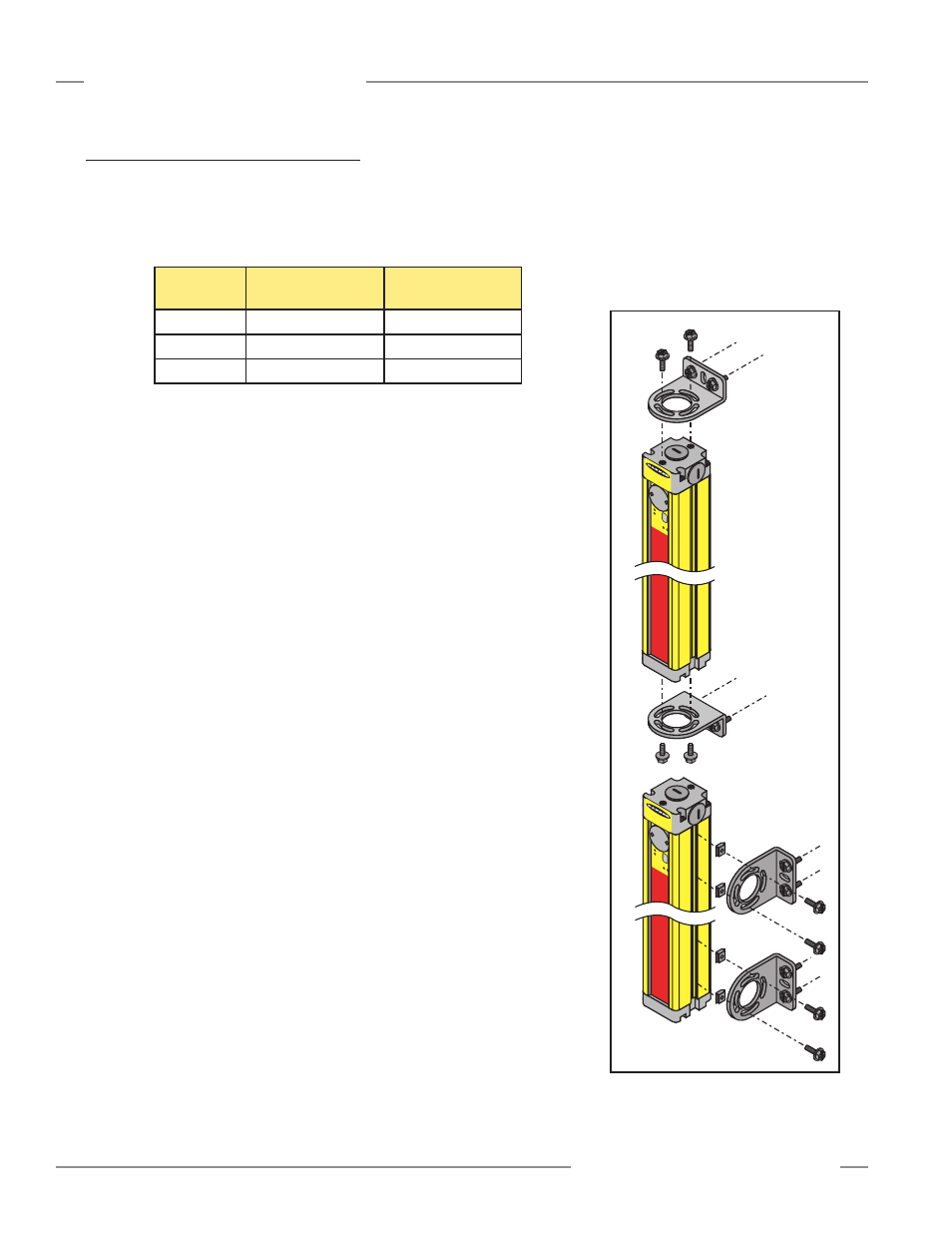

The emitter and the receiver must be mounted parallel to each other, with their

displays either both at the top or both at the bottom; see Figure 3-5. If corner

mirrors are used, they must also be mounted in the same parallel line.

Several mounting bracket options are available; refer to Section 2.2 for more

information. Brackets may attach directly to EZ-SCREEN sensor end caps, or at

any point along the sensor’s length, using the supplied T-nuts in the housing’s

side slots. Bracket dimensions are shown in Figure 2-1.

Standard Brackets

The standard brackets (EZA-MBK-1), included with each sensor, may attach to

the side of the housing or to the top and bottom end caps. If mounting to the end

caps, the beam path may run either parallel or perpendicular to the mounting

surface. The brackets allow ±30° rotation for beam alignment. Insert the two

included M5 screws through the slots in the brackets, into the end cap’s two

threaded holes.

If mounting to the end caps, see Section 3.5 for cable routing instructions prior

to attaching the housing to the bracket.

If side-mounting to the housing, lay the housing on its side and slide four T-nuts

into the slot on one side of the housing. Connect a bracket near the top and near

the bottom of the sensor, using two T-nuts and screws per bracket; see

Figure 3-9. For easier optical alignment, swivel brackets (described below) are

recommended when sensors will be side-mounted.

Stand-Mount Brackets

The accessory stand-mount brackets (EZA-MBK-2) are used in conjunction with

the standard brackets described above for mounting to an MSA Series stand.

They may also be used with a U-bolt for attaching to a round stand, such as

Machine Guard stand MGA-S72-1.

Swivel Brackets

The accessory swivel brackets (EZA-MBK-3) mount to the sides of the housing

using the same T-nuts used for the standard brackets. The two-part brackets

rotate up to 180° for easy alignment. After sensors are aligned (see Section 3.6),

tighten brackets firmly into place.

Adjustable Brackets

The adjustable brackets (EZA-MBK-9) mount to the housing top and bottom and

allow the space between the sensor and its mounting surface to be increased or

decreased. When fixed stands and bases are used, the EZA-MBK-9 brackets may

be used to provide the necessary adjustability for alignment.

1

1

ON

2

3

4

SC

AN

CO

DE

2

1

T

L

1

2

T

L

1

E

D

M

E

D

M

2

S

T

A

T

U

S

BE

AM

S

1

2

R

E

S

E

T

S

T

A

T

U

S

EZ-GUAR

D Grid

BA

NN

ER

EN

GIN

EE

RIN

G C

OR

P., U

SA

888

.37

3.6

767

1

1

ON

2

3

4

SC

AN

CO

DE

2

1

T

L

1

2

T

L

1

E

D

M

E

D

M

2

S

T

A

T

U

S

BE

AM

S

1

2

R

E

S

E

T

S

T

A

T

U

S

EZ-GUARD Grid

BA

NN

ER

EN

GIN

EER

ING

CO

RP.,

US

A

888

.373.

676

7

Figure 3-9. Attaching standard brackets

to the end caps or side of

the EZ-SCREEN

Banner Engineering Corp.

•

Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164