Rockwell Automation VSM500 Integrated Drive/Motor DeviceNet Option Board User Manual

Page 63

Parameters

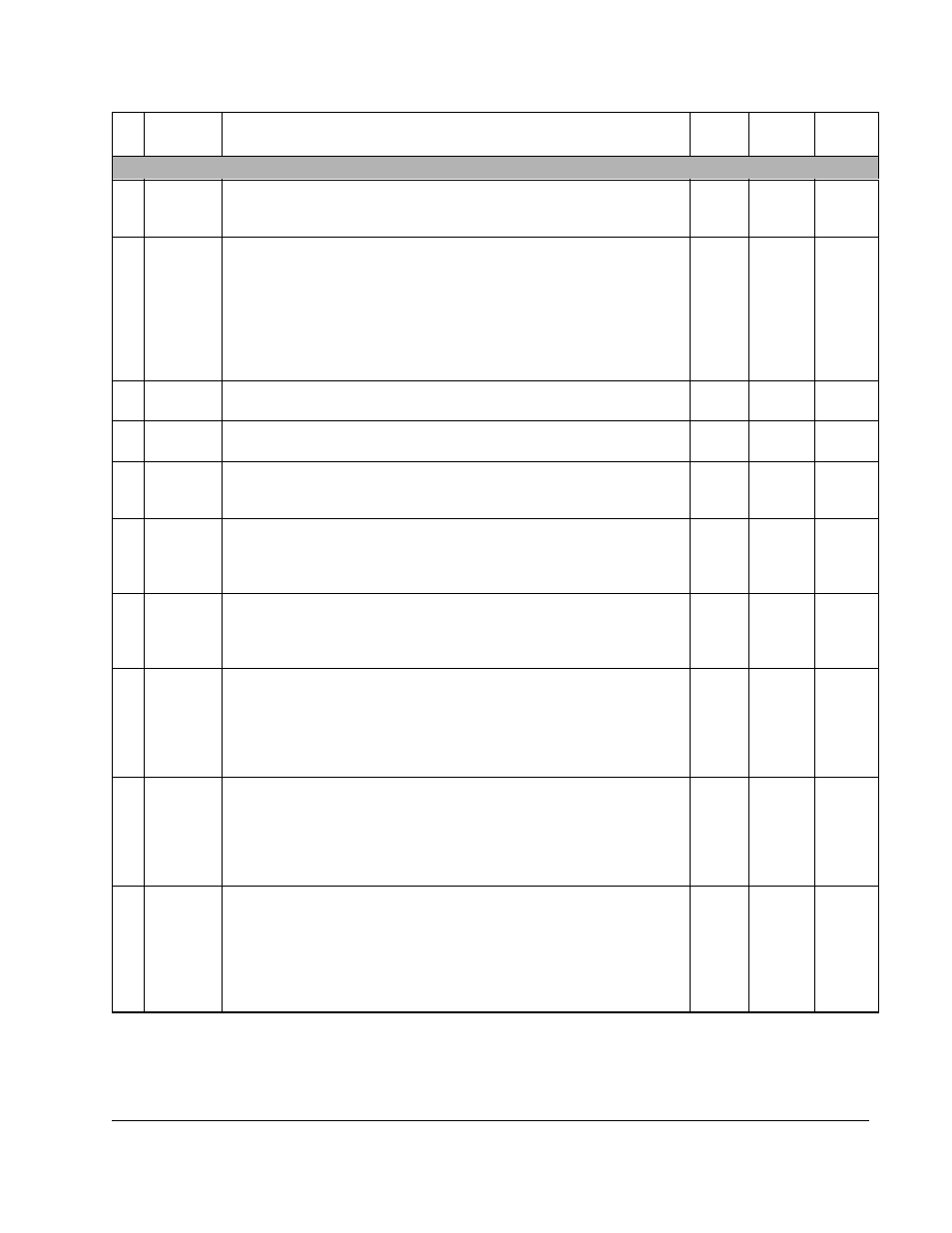

B-5

#

Object

Mapping

Name and Description

Access

Rule

1

Units/

Range

Factory

Default

Drive Program Parameters (continued)

39

0x0F-39-1

Auto Restart Delay

Time between restart attempts.

Get/

Set

1 Sec. to

60 Sec.

5 Sec.

40

0x0F-40-1

Torque Curve

Type of torque curve used by the VSM500 unit. A variable torque curve

provides a squared V/Hz curve, 110% electronic thermal overload, and

110% current limit for one minute. A constant torque curve provides a linear

V/Hz curve, 150% electronic thermal overload, and 150% current limit for

one minute.

0 = Variable Torque

1 = Constant Torque

Get/

Set

0 to 1

0

41

0x0F-41-1

Torque Boost

Commanded voltage when the drive output frequency is 0 Hz.

Get/

Set

0.0% to

250.0%

100.0%

42

0x0F-42-1

Base Frequency

Set value to rated nameplate frequency of the motor.

Get/

Set

10 Hz to

120 Hz

60 Hz

43

0x0F-43-1

Base Voltage

Commanded voltage when the drive output frequency is equal to

parameter 42 [

BASE

FREQUENCY

].

Get/

Set

20 to

Rated

Voltage

Rated

Voltage

44

0x0F-44-1

Stop Select

Stopping mode used by the drive when a stop is initiated.

0 = Coast to stop

1 = Ramp to stop

Get/

Set

0 to 1

0

45

0x0F-45-1

Reverse Disable

Disables reverse rotation of the motor.

0 = Reverse enabled

1 = Reverse disabled

Get/

Set

2

0 to 1

0

46

0x0F-46-1

IR Compensation

Compensation for the voltage drop across the stator resistance in an

induction motor. A voltage is added to the commanded output voltage

based on the load current. The default value of 100% is the factory

determined optimum for the drive. It can be adjusted higher or lower to suit

the needs of the application. A setting of 0% disables this function.

Get/

Set

0% to

150%

100%

47

0x0F-47-1

Slip Compensation

Compensation for the inherent slip in an induction motor. A frequency is

added to the commanded output frequency based on load current. The

default value of 100% is the factory determined optimum for the drive. It

can be adjusted higher or lower to suit the needs of the application. A

setting of 0% disables this function.

Get/

Set

0.0% to

150.0%

100.0%

48

0x0F-48-1

Analog Minimum

The percent of analog input used to represent parameter 30 [

MINIMUM

FREQUENCY

]. If the minimum analog input equals minimum frequency, no

action is needed. If it is desired to adjust the analog input to equal

parameter 30 [

MINIMUM

FREQUENCY

], use parameter 08 -[

ANALOG

INPUT

] to

adjust the analog input to the desired level and then enter the value in

parameter 48.

Get/

Set

2

0.0% to

100.0%

0%

1

Get = Read. Set = Write. Set access is allowed only if DIP switch 10 on the VSM500 Integrated drive/motor is set to On (figure 2.3).

2

The parameter can be set only when the drive is stopped.

3

The parameter can be set only then the VSM500 Integrated drive/motor does not have an active I/O connection.