Rockwell Automation LDC Iron Core Linear Servo Motors User Manual

Page 66

66

Rockwell Automation Publication LDC-UM001B-EN-P - March 2011

Appendix A Specifications and Dimensions

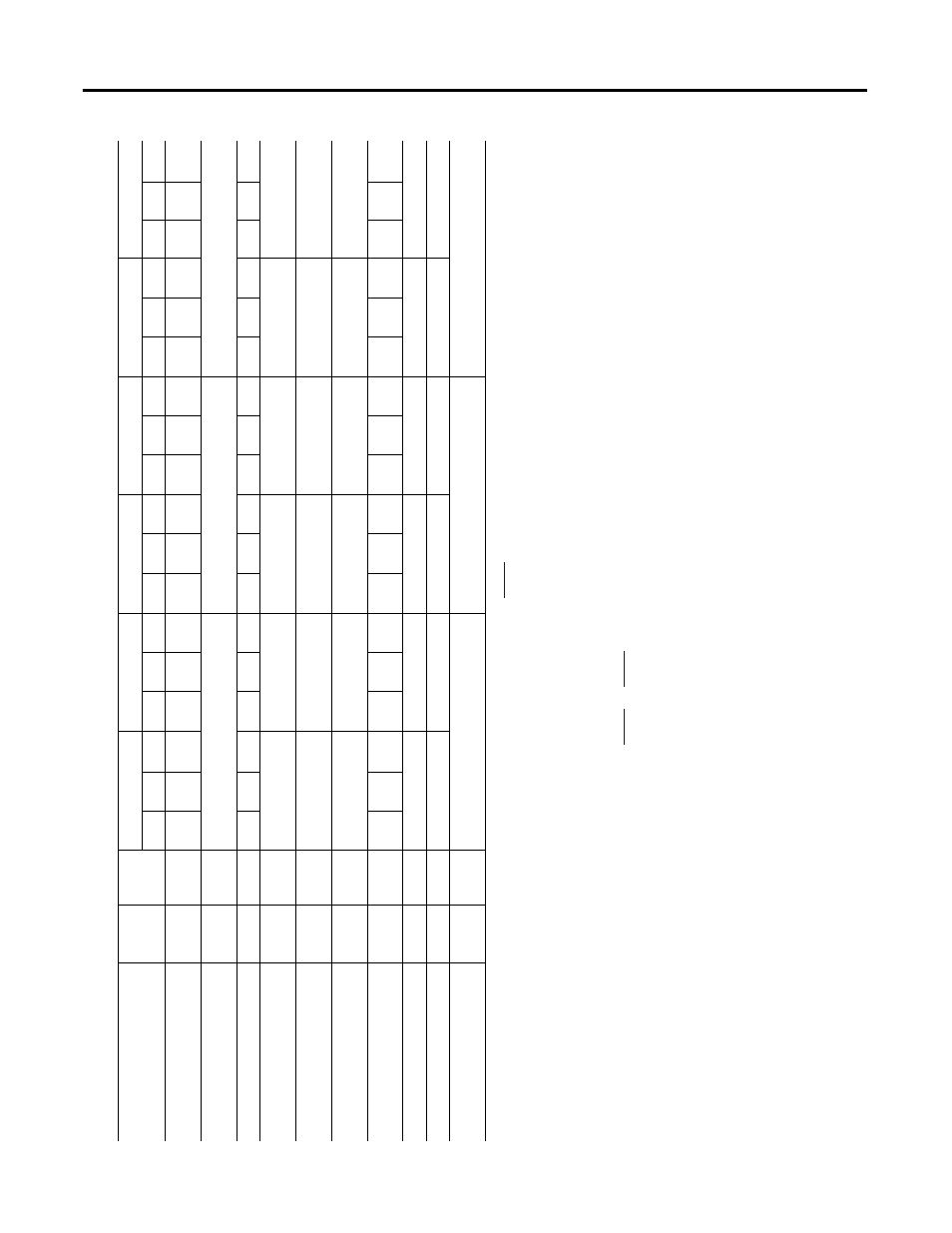

Ta

ble 11 - LDC-Se

rie

s Iro

n

Core

Linea

r Mot

o

rs (

100 m

m

frame

size)

Attribute

U

nits

Symbol

LD

C-C100

300-

D

x

T

xx

LD

C-C10

0300-

E

x

T

xx

LD

C-C1

00400

-D

x

T

xx

LD

C-C

100400

-E

x

T

xx

LDC-

C1006

00-D

x

T

xx

LDC-

C1006

00-E

x

T

xx

NC

AC

WC

NC

AC

WC

NC

AC

WC

NC

AC

WC

NC

AC

WC

NC

AC

WC

Force, continuou

s

(1)

(2)

(3)

N

(lbf)

F

c

674

(152)

843

(190)

1012

(227)

674

(152)

84

3

(190

)

1012

(2

27)

89

9

(202)

112

4

(253)

1349

(30

3)

89

9

(202)

1124

(2

53)

13

49

(303)

1349

(30

3)

1686

(379

)

202

3

(455)

1349

(3

03)

1686

(3

79)

202

3

(455)

Force, pea

k

(4)

N

(lbf)

F

p

1767

(397)

2356

(530)

3534

(79

4)

Therma

l resistan

ce

°C

/W

R

th

0.33

0.21

0.

15

0.33

0.

21

0.15

0.

25

0.16

0.1

1

0.

25

0.16

0.11

0.1

7

0.

11

0.07

0.17

0.11

0.07

Force c

onstant

(5

)

(6

)

(7)

N/

A

pk

(lbf/A

pk

)

K

f

60.7

(13.6

)

182

.0

(40.9)

60

.7

(13.6)

121.3

(27.3)

60.7

(13

.6)

121.3

(2

7.3)

Back

EMF constan

t p-

p

(5)

(6)

(7

)

V

p

/m/

s

(V

p

/i

n/s)

K

e

71.7

(1.

82)

215

.0

(5.

46)

71

.7

(1.82)

143.3

(3.64)

71.7

(1.82)

143.3

(3

.64)

Current, p

eak

(4)

(6)

A

pk

(A

rm

s

)

I

p

34.3

(24.2

)

11.4

(8.

1)

45

.7

(32.3)

22

.8

(16.1)

68.5

(48

.4)

34.3

(2

4.2)

Current, con

tinu

ous

(1)

(2)

(3

)

(6)

A

pk

(A

rms

)

I

c

11.1

(7.

9)

13.9

(9.

8)

16

.7

(11.8)

3.7

(2.

6)

4.

6

(3.3)

5.6

(3

.9)

14

.8

(10.5)

18.5

(13.1)

22.2

(15

.7)

7.

4

(5.2)

9.3

(6

.5)

11

.1

(7.9)

22.2

(15

.7)

27

.8

(19.7)

33.3

(23.6)

11.1

(7

.9)

13.9

(9

.8)

16.7

(11.8)

Resistance p-p @

20 °C (68 °F)

(5)

(7

)

Oh

ms

R

20

2.04

18.36

1.

53

6.

12

1.0

2

4.08

In

ductance p-p

(5

)

(7)

mH

L

20

184

15

61

10

41

Magnetic at

traction

(8)

N

(lbf)

F

a

3930

(883)

5240

(1178

)

7860

(17

67)

(1)

C

oils at

maximum

te

mperature

, 130 °C

(266 °F), mounte

d

to

an alumin

ium heat sin

k whose area is

note

d

in table

on

, and

at 40 °C

(104 °F)

am

bi

en

t.

(2)

C

ontinuou

s force and current based

on coil moving

with

al

l p

hases

sha

ring the same loa

d

in sinusoidal c

ommu

tatio

n.

(3)

For standstill c

onditions,

multiply cont

inuous force and continuous current by

0.

9.

(4)

C

alc

ulate

d

at

20

% duty c

ycle

fo

r

1.0 second max. So

me

ap

plicat

ions may

produ

ce

significantly h

ighe

r pe

ak forces. Call

Applic

at

ion

s Eng

ine

ering

(631.344.660

0) for details.

(5)

W

inding paramete

rs

listed are meas

ured

line

-to-line

(phase-to-p

hase).

(6)

C

urrent

s and voltages listed are me

asured 0-pea

k of the sine wave unless

note

d

as

rms.

(7)

S

pecifications are ±10%. Pha

se

-to-phase inductance is ±30%.

(8)

A

ll

specifications are at the

sta

ndard refere

nce

air gap as

sho

w

n

in the

dr

awin

g

on

pa

ge

73

a

nd

page

75

.