Rockwell Automation LDC Iron Core Linear Servo Motors User Manual

Page 64

64

Rockwell Automation Publication LDC-UM001B-EN-P - March 2011

Appendix A Specifications and Dimensions

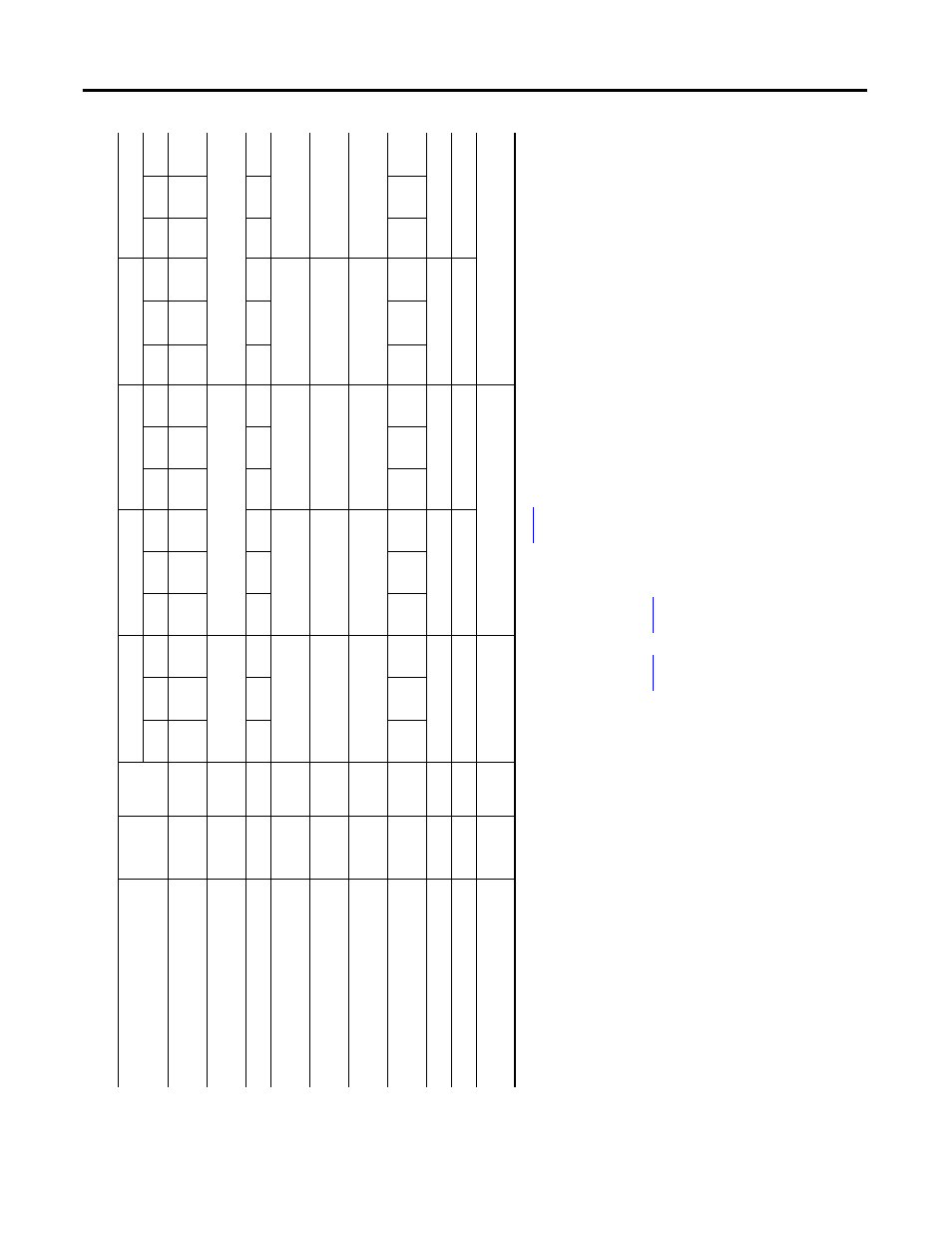

Ta

ble 9 - LDC-Se

rie

s Iro

n

Core

Linear Motors (50 mm frame size)

Attribute

U

nits

Sym

bol

LD

C-C

050

10

0-D

x

T

xx

LD

C-C

050

20

0-D

x

T

xx

LD

C-C

050

20

0-E

x

T

xx

LD

C-C0

50

30

0-D

x

T

xx

LD

C-C0

50

30

0-E

x

T

xx

NC

AC

WC

NC

AC

WC

NC

AC

WC

NC

AC

WC

N

C

AC

WC

For

ce

, co

ntin

uo

us

(1

)

(2

)

(3)

N

(lb

f)

F

c

11

9

(2

7)

14

9

(3

4)

17

9

(4

0)

24

0

(5

4)

29

9

(6

7)

35

9

(8

1)

24

0

(5

4)

29

9

(67)

35

9

(8

1)

36

3

(82)

45

3

(102)

54

4

(122)

36

3

(82)

45

3

(102)

54

4

(122)

Fo

rc

e, pe

ak

(4)

N

(lb

f)

F

p

30

2

(6

8)

60

0

(1

35

)

94

1

(212)

Th

er

mal

r

esi

st

an

ce

°C/W

R

th

1.44

0.92

0.64

0.71

0.46

0.

32

0.

71

0.

46

0.

32

0.

48

0.

31

0.

21

0.4

8

0.3

1

0.

21

For

ce

co

nsta

nt

(5

)

(6

)

(7)

N/A

pk

(lbf/A

pk

)

K

f

30

.3

(6

.8

)

30

.3

(6

.8

)

60

.7

(1

3.

6)

30

.8

(6.9)

92

.4

(2

0.8)

Ba

ck EM

F

co

nsta

nt p

-p

(5)

(6

)

(7

)

V

p

/m/s

(V

p

/in/s)

K

e

35

.8

(0

.9

1)

35

.8

(0

.9

1)

71

.7

(1

.8

2)

36

.4

(0.92)

10

9.1

(2.

77)

Cur

re

nt

, pe

ak

(4

)

(6

)

A

pk

(A

rms

)

I

p

11

.7

(8

.3

)

23

.3

(1

6.

5)

11

.6

(8

.2

)

35

.9

(25.4)

12

.0

(8.

5)

Cu

rre

nt

, con

tin

uo

us

(1

)

(2

)

(3

)

(6

)

A

pk

(A

rms

)

I

c

3.9

(2

.8

)

4.9

(3

.5

)

5.9

(4

.2

)

7.9

(5

.6

)

9.9

(7

.0

)

11

.8

(8

.4

)

3.9

(2

.8

)

4.

9

(3.5)

5.9

(4

.2

)

11

.8

(8.3)

14

.7

(1

0.

4)

17

.7

(12.5)

3.9

(2.

8)

4.9

(3.

5)

5.

9

(4.2)

Res

ist

an

ce

p-

p

@ 20

°C (6

8

°F)

(5

)

(7

)

Oh

ms

R

20

3.76

1.88

7.52

1.

25

11

.2

8

In

du

ct

an

ce p-

p

(5)

(7

)

m

H

L

361

87

2

12

10

8

Ma

gn

et

ic

at

tr

ac

ti

on

(8

)

N

(lb

f)

F

a

69

0

(1

55

)

13

79

(3

10

)

20

69

(465)

(1)

C

oils at

maximum

te

mperature

, 130 °C

(266 °F), mounted

to an alumin

ium heat sin

k whose area is noted

in table

on

, and at 40 °C

(104 °F)

amb

ient

.

(2)

C

ontinuous force and current based on coil moving

with

al

l p

hases

shar

ing the same loa

d

in sinusoidal c

ommut

atio

n.

(3)

For

standstill con

ditions, multiply

continuous force and continuous c

urrent by

0.9.

(4)

C

alc

ulate

d

at

20% duty c

ycle

fo

r

1.0 second max. So

me

ap

plicat

ions may

produ

ce

signif

icantly h

ighe

r pe

ak forces. Call

Applic

at

ion

s Eng

inee

ring

(631.344.6600

) for details.

(5)

W

inding parameter

s listed are meas

ured

line

-to-line

(phase-to-p

hase).

(6)

C

urrents and voltages listed are me

asured 0-peak of the sine wave unless

note

d

as

rms.

(7)

S

pecifications are ±10%. Phas

e-

to-phase in

ductance is ±30%.

(8)

A

ll specifications are at

the

stan

dard re

feren

ce

air

gap

as shown

in t

he d

rawing

on

pag

e

73

a

nd

page

75

.