Rockwell Automation LDC Iron Core Linear Servo Motors User Manual

Page 65

Rockwell Automation Publication LDC-UM001B-EN-P - March 2011

65

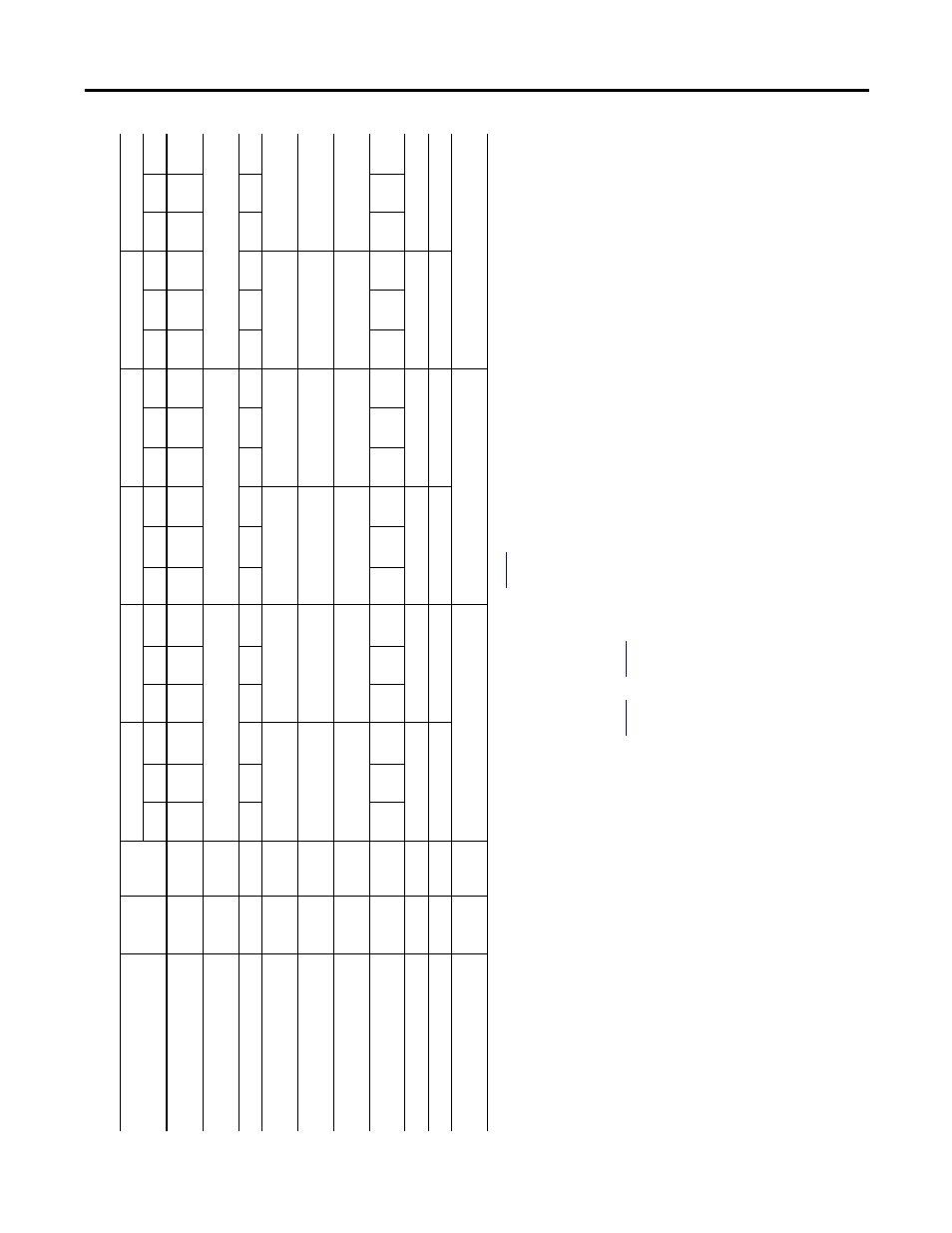

Specifications and Dimensions Appendix A

Tabl

e 10 - LDC-Series Iron Core Lin

ear Mo

tors (75 mm

fra

m

e size

)

Attrib

ute

U

nits

Symbol

LDC-

C0752

00-D

x

T

xx

LDC

-C075

200-E

x

T

xx

LD

C-C0

75300-

D

x

T

xx

LD

C-C

075300

-E

x

T

xx

LDC

-C075

400-D

x

T

xx

LD

C-C07

5400-

E

x

T

xx

NC

AC

WC

NC

AC

WC

NC

AC

WC

NC

AC

WC

NC

AC

WC

NC

AC

WC

Force, con

tinu

ous

(1)

(2

)

(3

)

N

(lbf)

F

c

348

(78

)

435

(98

)

523

(117

)

348

(7

8)

435

(98

)

523

(117

)

52

3

(117)

65

3

(147)

784

(1

76)

52

3

(117

)

653

(14

7)

784

(17

6)

697

(1

57)

87

1

(196)

1045

(23

5)

697

(157)

871

(1

96)

1045

(23

5)

Force, p

eak

(4)

N

(lbf)

F

p

882

(19

8)

13

68

(308)

1824

(4

10)

Th

ermal resis

tance

°C/W

R

th

0.5

8

0.3

7

0.26

0.58

0.3

7

0.26

0.39

0.

25

0.17

0.

39

0.2

5

0.1

7

0.29

0.19

0.1

3

0.29

0.19

0.1

3

Force constant

(5)

(6)

(7)

N/A

pk

(lbf/

A

pk

)

K

f

45.5

(10

.2)

91.0

(2

0.5

)

45

.5

(10.2)

136.5

(30.7)

45.5

(1

0.2

)

91.0

(20.5)

Back

EMF c

onstant p-p

(5

)

(6

)

(7)

V

p

/m/s

(V

p

/i

n/

s)

K

e

53.7

(1.37)

107.5

(2

.73

)

53

.7

(1.37)

161.2

(4.10)

53.7

(1

.37

)

107

.5

(2.

73)

Current, peak

(4

)

(6

)

A

pk

(A

rms

)

I

p

22.9

(16

.2)

11.5

(8

.1)

35

.6

(25.1)

11

.9

(8.4)

47.4

(3

3.5

)

23.7

(16.8)

Current, c

ontin

uous

(1

)

(2

)

(3)

(6)

A

pk

(A

rms

)

I

c

7.7

(5.

4)

9.6

(6.

8)

11.5

(8.

1)

3.8

(2

.7)

4.8

(3.

4)

5.7

(4.

1)

11

.5

(8.1)

14

.4

(10.2)

17.2

(1

2.2

)

3.

8

(2.7)

4.8

(3.

4)

5.7

(4.

1)

15.3

(1

0.8

)

19

.1

(13.5)

23.0

(16

.2)

7.7

(5.

4)

9.6

(6

.8)

11.5

(8.

1)

Resistan

ce

p-p

@ 2

0 °

C

(6

8 °

F)

(5

)

(7)

Ohms

R

20

2.4

7

9.88

1.65

14

.8

2

1.24

4.94

Inductan

ce

p-p

(5)

(7)

mH

L

24

95

16

142

12

47

Magne

tic attraction

(8)

N

(lbf)

F

a

2000

(45

0)

29

99

(674)

3999

(8

99)

(1)

C

oils

at maximum temperatu

re, 130

°C (26

6

°F

),

moun

ted

to a

n aluminiu

m hea

t sink who

se

area

is no

ted

in

table

on

, a

nd a

t 40

°C

(10

4 °

F)

ambie

nt.

(2)

C

on

tinuo

us for

ce

and

curren

t ba

se

d o

n coil

moving with

all phases s

harin

g

th

e

same load in sin

usoid

al commutation.

(3)

Fo

r

stand

st

ill conditio

ns, multiply

cont

inuo

us

force and continuou

s current by 0.9

.

(4)

C

alculated at

20

% duty cyc

le for 1.0

second max.

Some applicat

ions

may pro

duce significan

tly

hig

her peak forces. Ca

ll

Ap

plic

ations E

ngin

eering

(631

.34

4.66

00) for

deta

ils.

(5)

W

inding

para

m

et

ers liste

d are

m

easur

ed line-to-lin

e (phase-

to-phase).

(6)

C

urre

nts

an

d

voltage

s listed are measured

0-pe

ak

of the sin

e

wave unless

no

ted as

rms.

(7)

S

pe

ci

fic

ation

s

are

±10%. Ph

ase-to-pha

se

inductan

ce

is ±3

0%.

(8)

A

ll

spe

cific

at

ion

s are at the standard

refe

rence air gap as s

hown

in the drawing on

page

73

and

page

75

.