Understanding rbm connectors – Rockwell Automation 2090-XBxxx Resistive Brake Module Installation Instructions User Manual

Page 9

Publication 2090-IN009F-EN-P — November 2004

Resistive Brake Module Installation Instructions

9

Ensure all fasteners are properly bonded to the subpanel. Refer to the

System Design for Control of Electrical Noise Reference Manual (publication

GMC-RM001x-EN-P) for HF bonding techniques.

3. Tighten all mounting fasteners. The minimum recommended torque for

M6 (1/4 in. - 20) bolts is 1 Nm (9 in-lb).

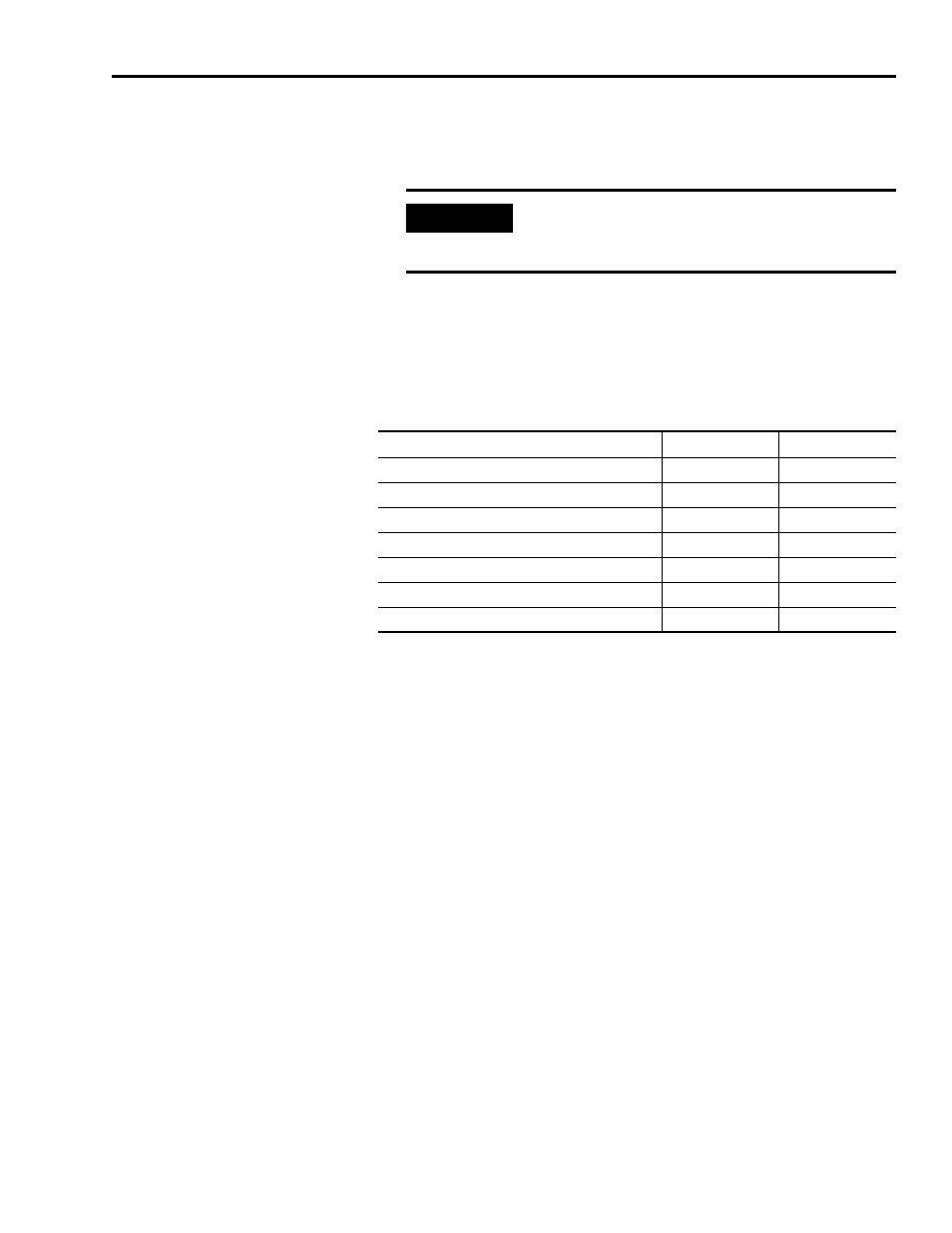

Understanding RBM

Connectors

RBMs have connectors and status indicators as listed in the following table:

• Connectors and indicators locations are shown in Figure 6 on page 10 for

the 2090-XB33-xx, and Figure 7 on page 10 for the 2090-XB120-xx.

• Block diagrams of electrical functions are provided as Figure 8 on page 11

for the 2090-XB33-xx, and Figure 9 on page 12 for the 2090-XB120-xx.

• Connector functions for the 2090-XB33-xx, and the 2090-XB120-xx are

described in RBM Wiring Requirements on page 13.

IMPORTANT

To improve the bond between the RBM and subpanel,

construct your subpanel out of zinc plated (paint-free)

steel.

RBM Connectors or Indicators

2090-XB33-xx

2090-XB120-xx

X

X

X

X

X

X

TB4 - 230VAC Aux Power Connection

–

X

X

–

–

X

–

X