Wiring the rbm to a drive system, 2090-xb33-xx block diagram, Attention – Rockwell Automation 2090-XBxxx Resistive Brake Module Installation Instructions User Manual

Page 11

Publication 2090-IN009F-EN-P — November 2004

Resistive Brake Module Installation Instructions

11

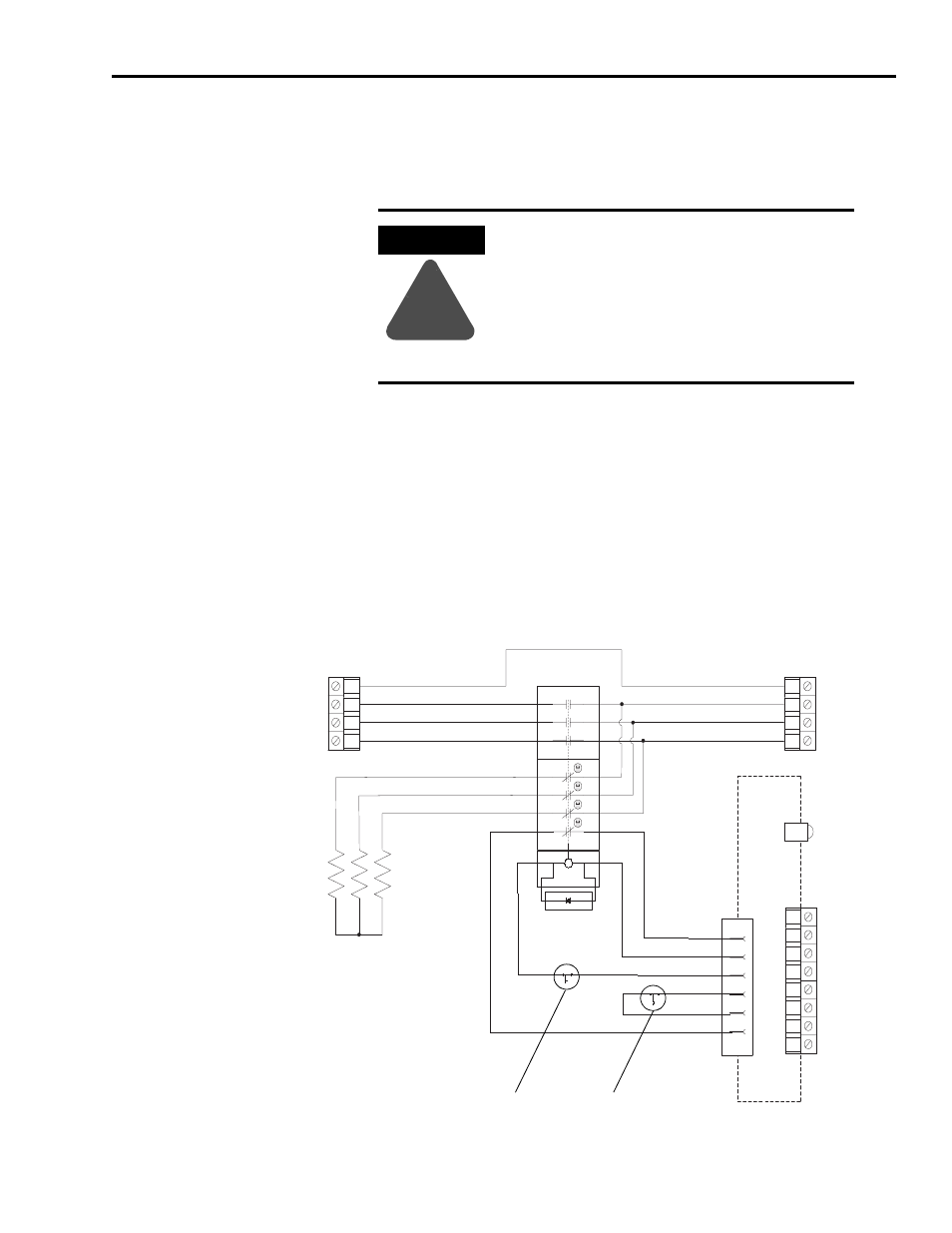

Wiring the RBM to a Drive

System

This section provides wiring instructions for the Resistive Brake Module

within a general drive system. Refer to Related Documentation on page 24 for

installation and integration instructions containing wiring information specific

to a drive system. In addition:

• Figure 1 on page 5 depicts suggested routing of RBM wiring within the

dirty noise zone.

• Figure 6 and Figure 7 on page 10 show connector locations and provides

pinouts for each RBM connector.

• Recommended wire sizes and torque values for I/O signal wires and

power wires are provided in RBM Wiring Requirements on page 13 and in

Specifications.

Figure 8

2090-XB33-xx Resistive Brake Module Block Diagram

ATTENTION

!

To comply with UL 508C, a Resistive Brake Module

must be protected upstream by a 2.5 kV overvoltage

control device.

Kinetix and Ultra servo drives from Rockwell

Automation meet this requirement. For additional

drive applicability, please consult your Allen-Bradley

representative.

1

2

3

4

5

6

11

12

21

22

31

32

41

42

A1

A2

D1

1

2

3

4

1

2

3

4

1

2

3

4

5

6

7

8

Ground

TB1 - Drive

Connection

W Drive

V Drive

U Drive

Ground

TB2 - Motor

Connection

W Motor

V Motor

U Motor

TS_21

TB3 - I/O

TS_22

CONSTAT_41

CONSTAT_42

SHIELD

COIL_A1

COIL_A2

SHIELD

Status LED

T2 (Warning)

T1 (Fault)

Printed

Circuit

Board

100S-C23

CR1