Rbm wiring requirements, L_a1, L_a2 – Rockwell Automation 2090-XBxxx Resistive Brake Module Installation Instructions User Manual

Page 13

Publication 2090-IN009F-EN-P — November 2004

Resistive Brake Module Installation Instructions

13

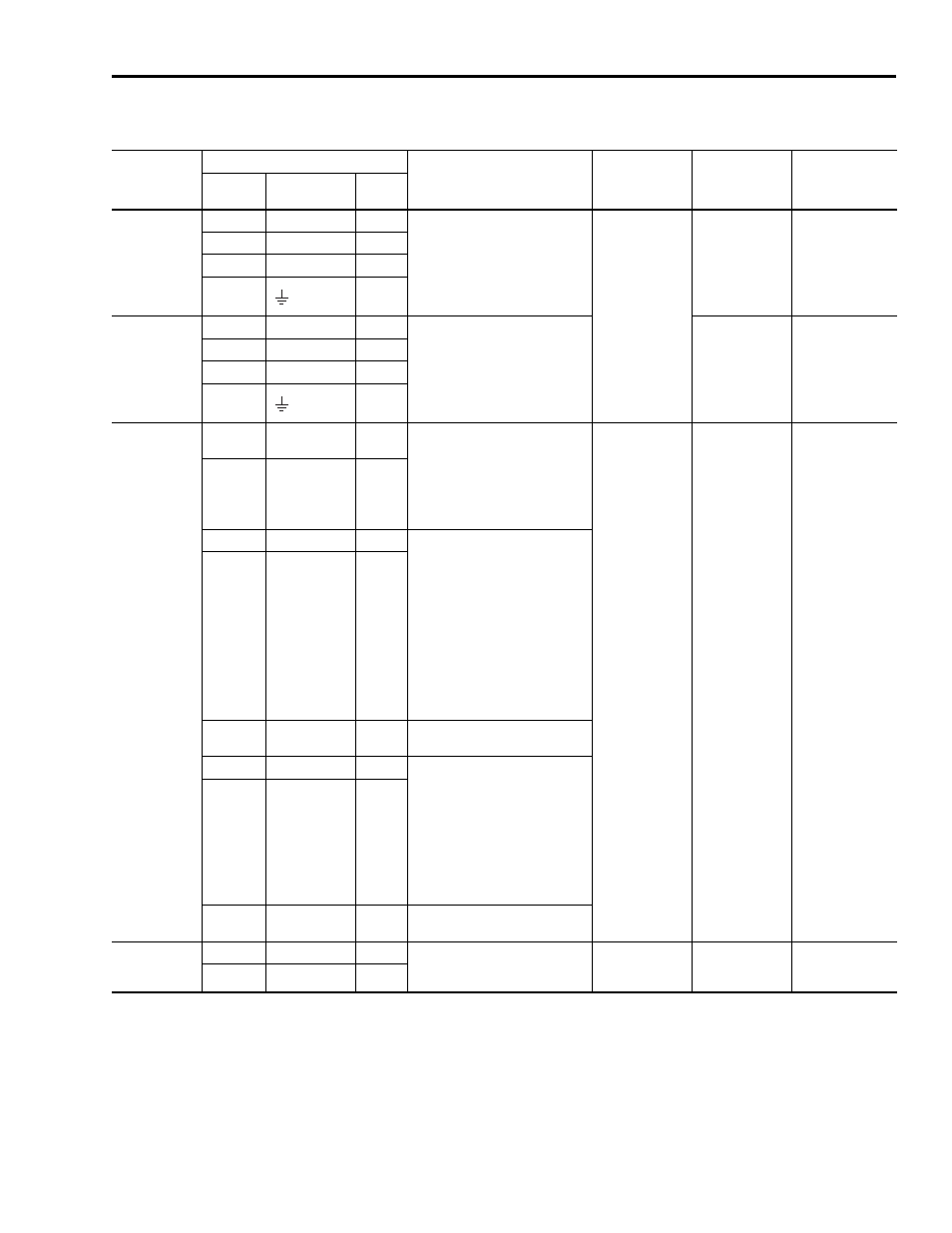

RBM Wiring Requirements

Connector

Connects to:

Description and Usage

Recommended

Wire Size

4

mm

2

(AWG)

Insulation Strip

Length

mm (in.)

Torque Value

Nm (lb-in.)

Terminal

-Pin

Signal

Input/

Output

Drive

Connection

1

TB1-1

U Drive

–

230/460V power input from drive

Minimum gauge

for power cable

is dependent on

the motor/drive

combination,

2090-XB33-xx

6 (10) maximum

2090-XB120-xx:

25 (3) maximum

2090-XB33-xx

10.0

(0.375)

2090-XB120-xx:

16.0

(0.63)

2090-XB33-xx:

0.5 - 0.6

(4.4 - 5.3)

2090-XB120-xx:

2.5 - 2.9

(22.1 - 25.7)

TB1-2

V Drive

–

TB1-3

W Drive

–

TB1-4

2

–

Motor

Connection

1

TB2-1 U

Motor

–

230/460V power output to motor

2090-XB33-xx

10.0

(0.375)

2090-XB120-xx:

16.0

(0.63)

2090-XB33-xx:

0.5 - 0.6

(4.4 - 5.3)

2090-XB120-xx:

2.5 - 2.9

(22.1 - 25.7)

TB2-2 V

Motor

–

TB2-3 W

Motor

–

TB2-4

2

–

I/O Signals

5,6

TB3-1

TS_21

In

RBM output with integral thermal

warning

Customer use of this auxiliary

contact may include:

• PLC or control string input that

RBM is nearing its thermal

limit

1.5 - 0.08

(16 - 28)

6.0

(0.25)

0.22 - 0.25

(1.9 - 2.2)

TB3-2 TS_22

Out

TB3-3

CONSTAT_41

In

RBM output of a normally closed

contact

(Closed = motor disconnected

from drive)

Customer use of this auxiliary

contact may include:

• PLC input connection,

indicating RBM contactor

status

• Safety relay input for safety

string

• Part of RBM safety string for

mechanical redundancy

TB3-4 CONSTAT_42 Out

TB3-5 SHIELD

3

–

I/O Shield internally terminated at

chassis ground

TB3-6

COIL_A1

In

RBM contactor coil with integral

thermal fault. Applying 24V Coil

Power picks-up the contactor,

which connects drive power to

motor leads (i.e., motor rotates).

Customer use may include:

• Control from a safety relay

output or signal relay output

indicating system is clear for

rotation

TB3-7 COIL_A2

Out

TB3-8 SHIELD

3

–

I/O Shield internally terminated at

chassis ground

230V Power

7

(2090-XB120-x

x only)

TB4-1

L1

–

Auxiliary power input from

external 230 VAC power source

(2090-XB120-xx only)

4.0 - 0.2

(10 - 24)

7.0

(0.28)

0.5 - 0.6

(4.4 - 5.3)

TB4-2 L2

–

1 Connectors are keyed to prevent misconnection of power interface cables to and from the RBM.

2 Ground connection for the motor cable passes through the drive and motor connectors.

Cable shielding must be grounded to the chassis via the spring-loaded cable clamps.

3 I/O Shield terminations are connected internally to chassis ground.

4 Wire supplied by user should be stranded copper with 75° C (167° F) minimum rating. An earth ground connection is required for safe and proper operation. Local agency

rules apply.

5 For additional contactor applications, refer to the Allen-Bradley Safety Product Catalog (Publication S114-CA001A-EN-P).

6 I/O is powered by an external 24V (22.4 - 26.4), 0.5A power supply.

7 Provided by an external 230V (207 - 253), 1A power supply.