Rockwell Automation 1747-ACNR15 ControlNet Adapter Module User Manual User Manual

Page 132

Publication 1747-UM003A-EN-P

B-40 Understanding Your SLC 500/1746 Control System

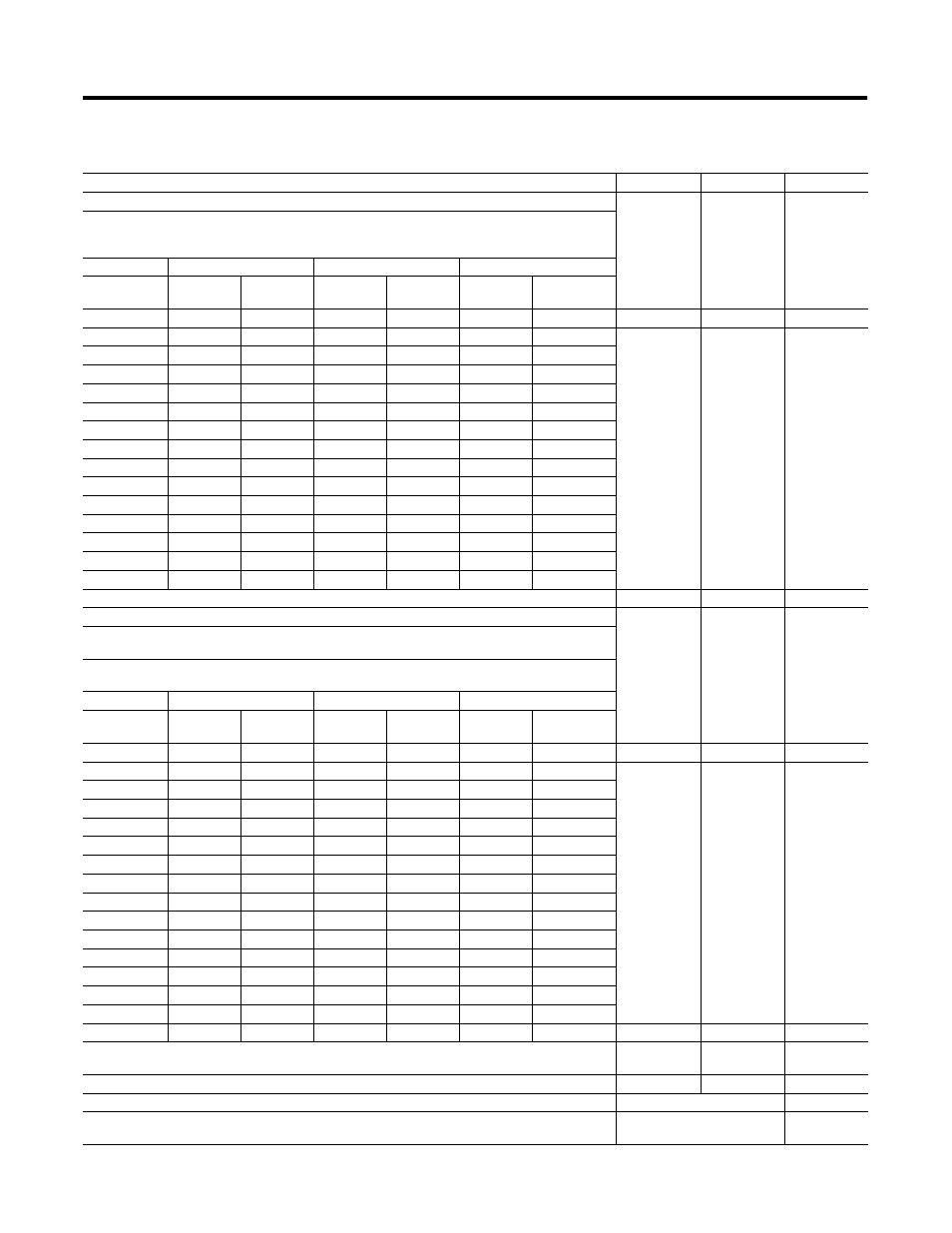

Example - Worksheet for Calculating Heat Dissipation

Procedure:

Chassis 1

Chassis 2

Chassis 3

1. Calculate the heat dissipation for each chassis without the power supply

A. Write in the watts (calculated watts or total watts) dissipated by the processor, I/O and specialty

modules, and any peripheral devices attached to the processor. Then, for each chassis, add these

values together.

Chassis 1

Chassis 2

Chassis 3

Slot

Catalog

Number

Heat

Dissipation

Catalog

Number

Heat

Dissipation

Catalog

Number

Heat

Dissipation

0

L511

1.75

IA16

4.8

1

BAS

3.8

IA16

4.8

2

IA8

2.4

OW16

5.5

3

OV8

6.9

OW16

5.7

4

5

6

7

8

9

10

11

12

peripheral

DTAM

2.5

TOTAL

17.35

20.8

B. Place the heat dissipation for each chassis into the appropriate columns.

2. Calculate the heat dissipation for each power supply

A. Calculate the power supply loading for each chassis (write in the minimum

watts for each device, and then, for each chassis, add these values together.

Important: If you have a device connected to user power, multiply 24V by the

current used. Include user power in the total power supply loading

Chassis 1

Chassis 2

Chassis 3

Slot

Catalog

Number

Min. Heat

Dissipation

Catalog

Number

Min. Heat

Dissipation

Catalog

Number

Min. Heat

Dissipation

0

L511

1.75

IA16

0.425

1

BAS

3.750

IA16

0.425

2

IA8

0.250

OW16

5.17

3

OV8

0.675

OW16

5.17

4

5

6

7

8

9

10

11

12

user power

2.4

peripheral

DTAM

2.5

TOTAL

8.925

13.59

B. Use the power supply loading for each chassis to determine the power supply dissipation. Place the

power supply dissipations into the appropriate columns.

3. Add the chassis dissipation to the power supply dissipation.

4. Add across the columns for the total heat dissipation of your SLC 500 controller.

TOTAL (Watts)

5. Convert to BTUs/hr.

Multiply the total heat dissipation of your SLC 500 controller by 3.414.

TOTAL (BtUs/hour)