Auxiliary contacts inspection and replacement – Rockwell Automation 1512A MV Controllers, 400A One-High Cabinet, Standard and Arc-Resistant Enclosure User Manual

Page 66

58

Rockwell Automation Publication 1512A-UM100F-EN-P - May 2013

Chapter 5

Maintenance

3. To adjust the distance from the blades to the bar, disconnect the threaded

connecting rod at the handle operating lever.

4. Turn the threaded connecting rod to lengthen or shorten it. This will

adjust the position of the isolation switch blades in the ON and OFF

position.

Auxiliary Contacts Inspection

and Replacement

1. Complete the Power Lockout Procedure (refer to

).

2. Inspect the auxiliary contacts for wear, scorching or heat damage. Replace

any damaged contacts. The contacts have a mean time between failure

(MTBF) rating of 20 million operations if used within the operating

specifications.

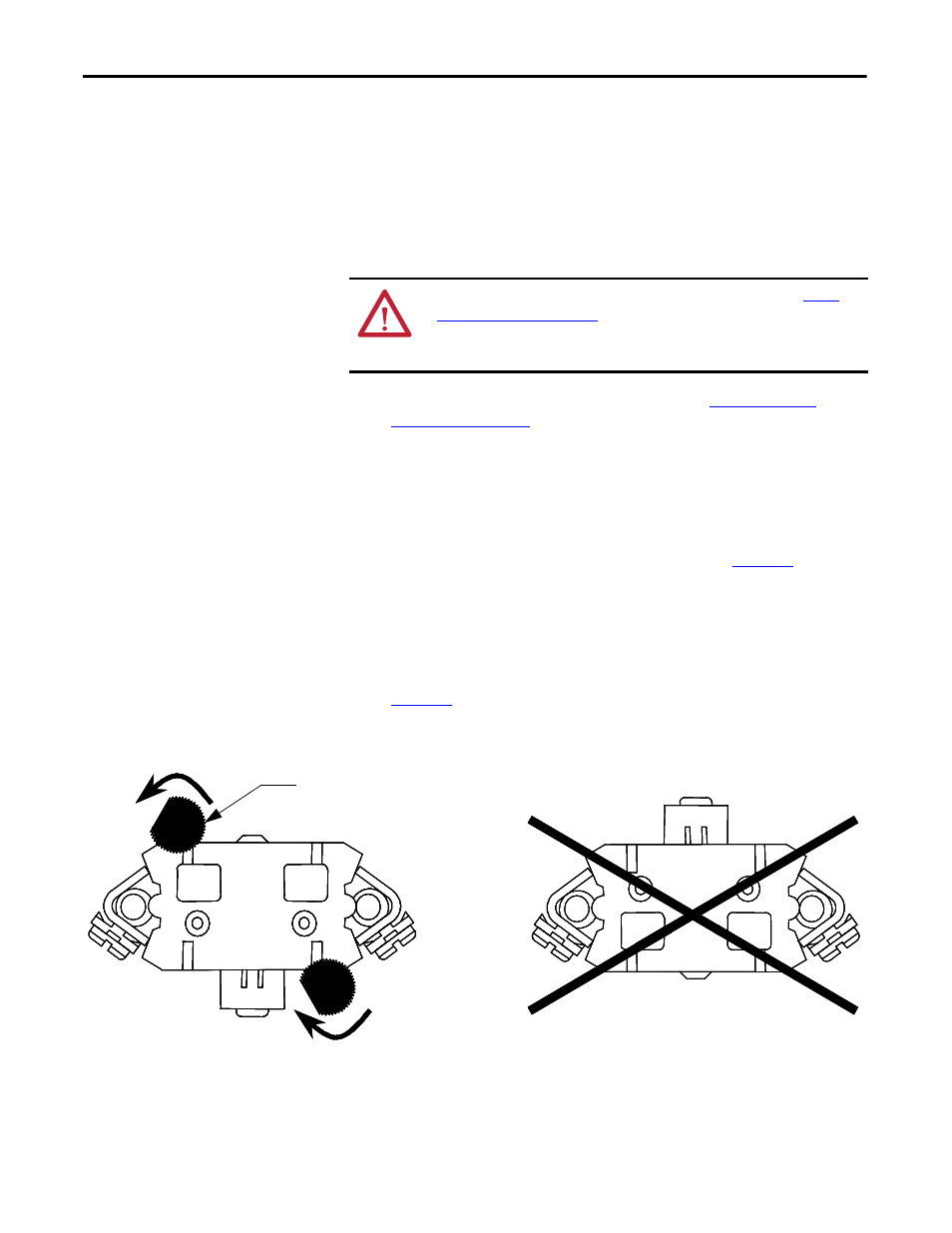

3. To remove the contact, turn both of the D-head fasteners until the flat

sections are aligned with the edge of the contact (See

).

4. Remove the contact from the housing.

5. Disconnect the wires from the auxiliary contact.

6. Reverse the procedure to replace the auxiliary contact.

7. Ensure the contact is correctly positioned into the contact carrier (see

).

Figure 59 - Auxiliary Contact Orientation

ATTENTION: To avoid shock hazard, lock out incoming power (refer to

) before working on the equipment. Verify with a

hot stick or appropriate voltage measuring device that all circuits are voltage

free. Failure to do so may result in severe burns, injury or death.

CATALOG NO.

700-CPM

SER. A

20

AMP

CATA

LOG NO.

700-CPM

SER. A

20

AMP

CATALOG NO.

700-CPM

SER. A

20

AMP

CATALOG NO.

700-CPM

SER. A

20

AMP

CATA

LOG NO.

700-CPM

SER. A

20

AMP

CATA

LOG NO.

700-CPM

SER. A

20

AMP

D-head Fastener

Correct

Incorrect