Rockwell Automation 1512A MV Controllers, 400A One-High Cabinet, Standard and Arc-Resistant Enclosure User Manual

Page 44

36

Rockwell Automation Publication 1512A-UM100F-EN-P - May 2013

Chapter 4

Common Installation

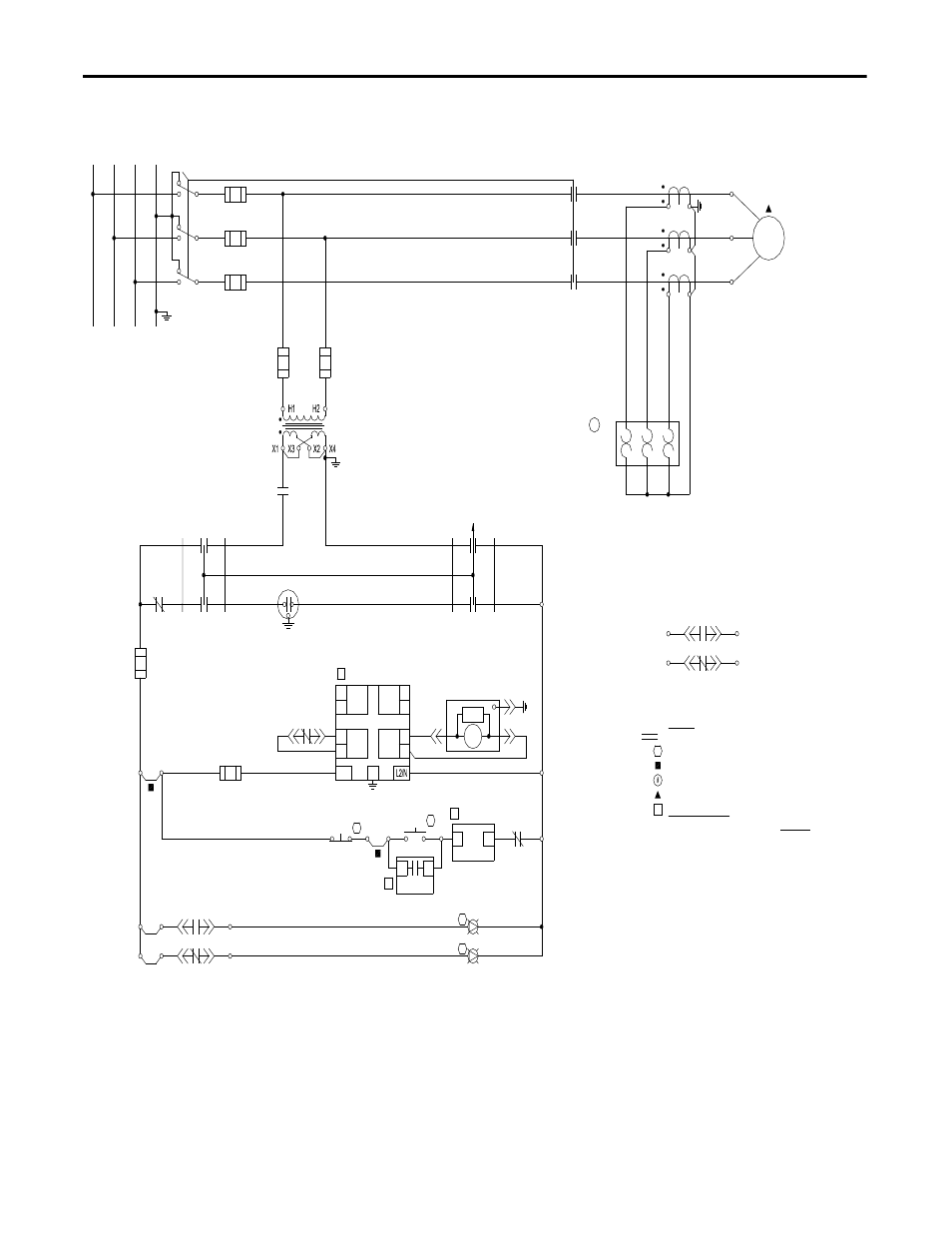

Figure 39 - Typical Wiring Diagram: Electrically Held Vacuum Contactor (with IntelliVAC Control)

Typical Wiring Diagram: Electrically Held Vacuum Contactor (Relay Control)

L1

L3

L2

GRD

MTR

ISOLATING SWITCH

DOOR INTERLOCK

CURRENT LIMITING

POWER FUSES

TEST SUPPLY POINT

X

X

PRIMARY FUSES

CURRENT LIMITING

V

VA

V

OVERLOAD

592

REMOTE EQUIPMENT

"IEEE" NUMBER FOR PROTECTIVE DEVICE

LOW VOLTAGE DOOR MOUNTED DEVICE

D

CUSTOMER WIRING

LEGEND

2400V-6900V,3Ø, 50/60Hz

INTELLIVAC TO BE PROGRAMMED/CONFIGURED BY THE

POWER APPLIED. THE FOLLOWING FACTORY INSTALLED

OUTPUT RELAY CONTACTS SHOWN WITHOUT CONTROL

MODULE STATUS - FAIL SAFE

CONTACTOR STATUS - FAIL SAFE

CUSTOMER BEFORE START-UP.

CONFIGURATION/POWER-UP STATES ARE IN EFFECT:

INTELLIVAC NOTES:

V

- INTELLIVAC MODULE VACUUM CONTACTOR AUXILIARY INPUT

AUX

- INTELLIVAC MODULE EXTERNAL CAPACITOR INPUT

EC

- INTELLIVAC MODULE CLOSING COIL OUTPUT

CCO

- MAIN CONTACTOR INTELLIVAC MODULE

M-IV

- INTELLIVAC MODULE TRIP COIL OUTPUT

TCO

REMOVE JUMPER WHEN CONNECTING REMOTE EQUIPMENT

EXTRA AUXILIARY

CONTACTS

MOV

3

2

1

EC

-

+

4

TCO

12

11

AUX

CCO

5

6

L1

G

+ -

V

V

STOP

D

START

D

V

D

D

RUN

OFF

MAIN

CONTACTOR (M)

37

K M L

36

33

H

M

32

G

35

34

1

I

J

M

31

M F

30

E

1

OL

4

M-IV

15

16

CONTACTOR

STATUS

3

2

1A

14

M-IV

9

10

CLOSE

12

14A

F7

2.0A

17

13

15

20

A

B

M

M-IV

M

M

N

C

1

12

(1)

(2)

(3)

(4)

NORMAL

OFF

TEST

X

X

47

46

44

42

OL

49

TS

F3

__E

F2

__E

F2

____

120

500

CPT1

M

(6)

(5)

(7)

(8)

12

ISa

5

IS

T2

T1

CT2

CT1

T3

CT3

11

6

10

F1

F1

F1

7

8

9

ISb

50/60Hz

120V