Contactor interlock rod adjustment – Rockwell Automation 1512A MV Controllers, 400A One-High Cabinet, Standard and Arc-Resistant Enclosure User Manual

Page 57

Rockwell Automation Publication 1512A-UM100F-EN-P - May 2013

49

Maintenance

Chapter 5

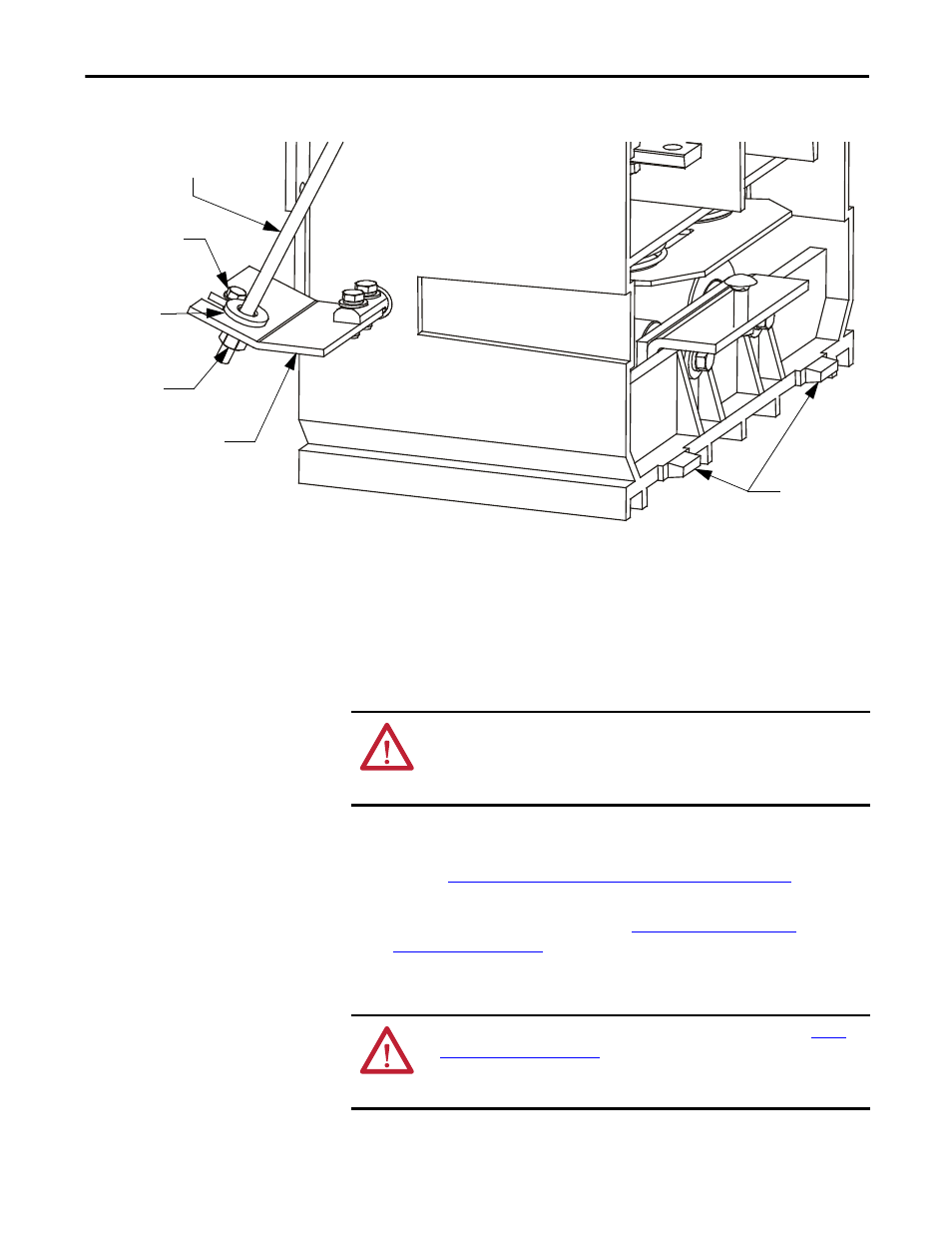

Figure 48 - Removing the Contactor

8. Remove the two contactor mounting bolts at the front of the contactor.

9. Slide the contactor forward slightly to disengage the retaining tabs at the

rear of the contactor from the mounting bracket inside the cabinet.

10. Carefully remove the contactor from the cabinet.

11. If the contactor is being replaced with a new one, move the contactor

interlock lever to the new contactor.

12. Reverse the procedure to reinstall the contactor. Ensure the mounting

bolts, power cable hardware and bus bar hardware is properly torqued.

Refer to

Recommended Torque Values on page 2 of Chapter 1

13. Adjust the contactor interlock rod according to the Contactor Interlock

Rod Adjustment procedure. Refer to

.

Contactor Interlock Rod

Adjustment

Contactor Interlock Rod

Nylon Contactor

Bushing

Retaining Screw

Nylon

Contactor

Bushing

Nyloc Nut

Contactor Operating Lever

Contactor

Remaining Tabs

ATTENTION: The contactor weighs approximately 22 kg (50 lb) and assistance

may be required to safely remove it from the cabinet and transport it. Failure to

use caution when moving the contactor may result in equipment damage

and/or personal injury.

ATTENTION: To avoid shock hazards, lock out incoming power (refer to

) before working on the equipment. Verify with a

hot stick or appropriate voltage measuring device that all circuits are voltage

free. Failure to do so may result in severe burns, injury or death.