Appendix d – Rockwell Automation 1305 AC Drive, Series A and B, Firmware 4.xx-5.xx User Manual

Page 167

Appendix D –

CE Conformity

D-1

EMC DIRECTIVE

This apparatus is tested to meet Council Directive 89/336

Electromagnetic Compatibility (EMC) using a technical

construction file and the following standards, in whole or in

part:

D EN 50081-1, -2 – General Emission Standard

D EN 50082-1, -2 – General Immunity Standard

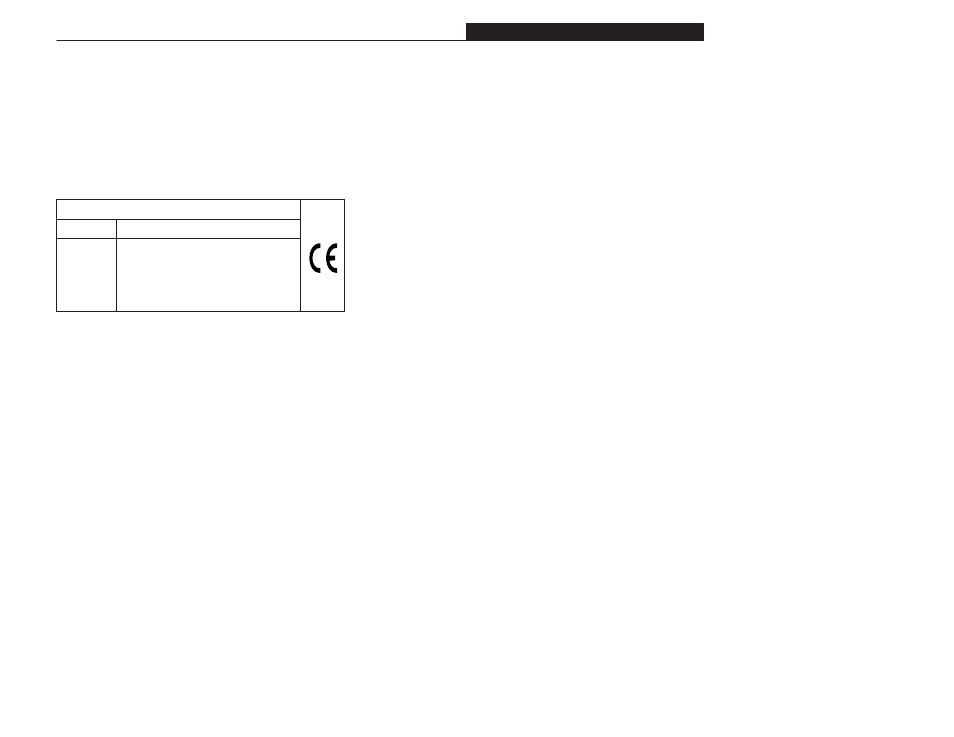

Table D.1 EMC Directives

Marked for all applicable directives

Emissions

EN55 011/CISPR 11 Level B

Immunity

EN50 082-1:1992

(IEC 801-2, IEC 801-3, IEC 801-4)

EN50 082-2:1995

(EN 61000-4-2, ENV 50140/50204,

EN 61000-4-4, ENV 50141, EN 61000-4-8,

IEC 801-6)

IMPORTANT: The conformity of the drive and filter to any

standard does not guarantee that the entire installation will

conform. Many other factors can influence the total installation

and only direct measurements can verify total conformity.

REQUIREMENTS FOR CONFORMING INSTALLATION

The following six items are required for CE conformance:

1.

CE marked product in NEMA Type 1 (IP30) configuration.

2.

Filter and Metal Plate Kit catalog numbers are listed in Table

D.2 on the following page. One Filter and one Metal Plate Kit

are required. The metal bonding plate MUST be inserted and

bonded to the drive heatsink.

3.

Grounding as shown on page D-3. The Green & Yellow ground

wire connects to the TB1 GRD terminals and the shield

terminates at the compact strain relief connector with double

saddle clamp (see item 5).

4.

Maximum cable length (drive to motor) of 75 meters

(250 feet). For applications greater than 9 meters (30 feet), refer

to recommendations tabulated in ”Motor Lead Lengths” (see

Chapter 2).

5.

Input power (source to filter) and output power (drive to motor)

wiring must be in braided shielded cable with a coverage of 75%

or better, metal conduit or other with equivalent or better

attenuation, mounted with appropriate connectors. For shielded

cable it is recommended to use a compact strain relief connector

with a double saddle clamp for filter and drive input and a

compact strain relief connector with EMI protection for motor

output.

6.

Control (I/O) and signal wiring must be in shielded cable

connected to the drive with a compact strain relief connector

with EMI protection.