Heavy duty dynamic braking 34 – Rockwell Automation 1336_F_E_T_S SERIES A CHOPPER BRAKE MODULE User Manual

Page 34

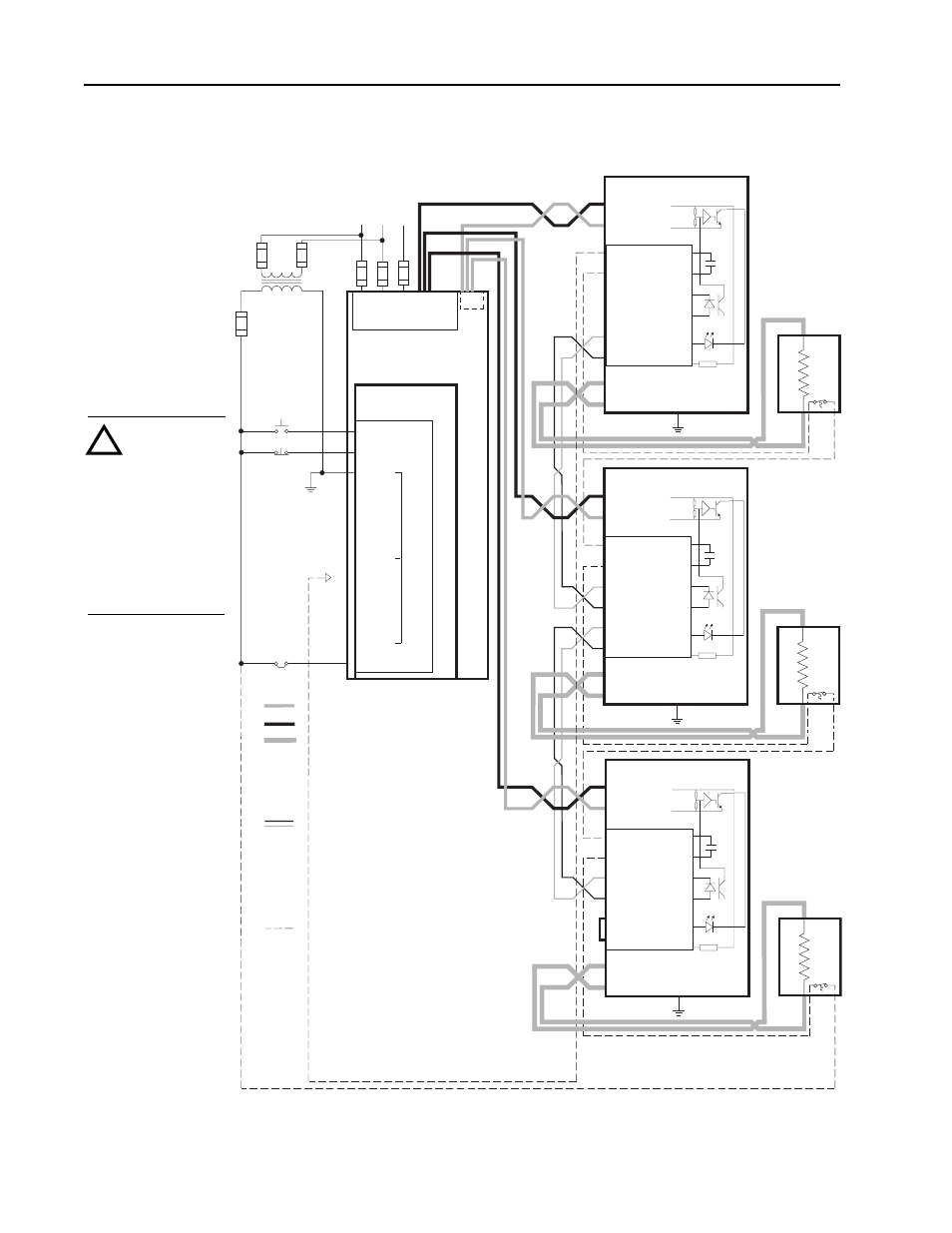

Heavy Duty Dynamic Braking

34

1336-5.65 — March, 2007

L1

L2

L3 +DC -DC

TB1

Drive

TB3

20

STOP

19

START

START

115V AC

21

COM

22

23

24

25

COM

26

27

28

29

COM

30

ENABLE

STOP

CUSTOMER

ENABLE

➊

E12

EXT RESISTORS

E11

EXT RESISTORS

4

(+) SLAVE IN

3

(–) SLAVE IN

5

(–) MASTER OUT

6

(+) MASTER OUT

1

AUX CONT

2

AUX CONT

➌

TB1

E10

(–) DC BUS

E9

(+) DC BUS

Master Brake

➍

➋

E12

EXT RESISTORS

E11

EXT RESISTORS

4

(+) SLAVE IN

3

(–) SLAVE IN

5

(–) MASTER OUT

6

(+) MASTER OUT

1

AUX CONT

2

AUX CONT

➌

TB1

E10

(–) DC BUS

E9

(+) DC BUS

Slave Brake

➍

➋

E12

EXT RESISTORS

E11

EXT RESISTORS

4

(+) SLAVE IN

3

(–) SLAVE IN

5

(–) MASTER OUT

6

(+) MASTER OUT

1

AUX CONT

2

AUX CONT

➌

TB1

E10

(–) DC BUS

E9

(+) DC BUS

Slave Brake

➍

➎

MOD-L6 or MOD-L3

Option

➎

➎

-DC Brake Power Wiring

+DC Brake Power Wiring

Brake Resistor Wiring

All Brake Power and Brake Resistor

Wiring must be twisted wire run in conduit

separate from Control Wiring. Size wire

according to NEC and local guidelines.

Control Wiring

All Control Wiring must be twisted wire run in

conduit separate from DC Brake Power Wiring.

Interconnection Control Wiring between the brake

terminals must be twisted pair, 1

mm

2

(18

AWG)

minimum.

Typical Brake Fault Contact Wiring

Connect to AUX at TB3 — Terminal 24 for

L6 Option — Terminal 28 for L3 Option.

MASTER OUT terminals are factory jumpered and

must remain jumpered for single brake applications.

For multiple brake applications, remove the jumpers

in all but the last enclosure.

Contact is shown in a de-energized state. Contact is closed

when power is applied and relay is energized. Loss of power or

a brake malfunction will open contact.

➊

➋

➌

Connect the brake frame to earth ground. Refer to the connected drive's User Manual for grounding instructions.

Optional overtemperature switch.

➍

➎

➋

-BRK

WA070, WB035 and WC035

WA115, WB110 and WC085

Multiple Brake

Wiring Scheme

For Drive Catalog

Numbers:

1336F –

BRF150

BRF200

ATTENTION:

Damage to drives

can result from

improper wiring.

Read drive

nameplate to

confirm catalog

number and rating

code to determine

correct wiring

diagram.

!