Procedure (cont.) – Rockwell Automation 1336VT AC DRIVE 5-300AMP (2-160KW) PROGRAMMING MANUAL User Manual

Page 86

Start and Run Boost Settings

Appendix A

A-4

Procedure (cont.)

4. Stop the drive and set drive frequency to the highest operating point

required by the application (typically 60 Hz).

5. Construct a custom start and run DC boost curve by setting Parameter 9

to 12.

•

Set start boost (Parameter 48) to a value that will be 3 volts greater

than the DC boost set in step 3.

•

Set run boost (Parameter 83) to

2

/

3

of the value of Parameter 48.

6. Start the drive.

The motor should accelerate smoothly to the maximum frequency. If

not, starting torque may be optimized by increasing start boost

(Parameter 48) in 1 volt increments.

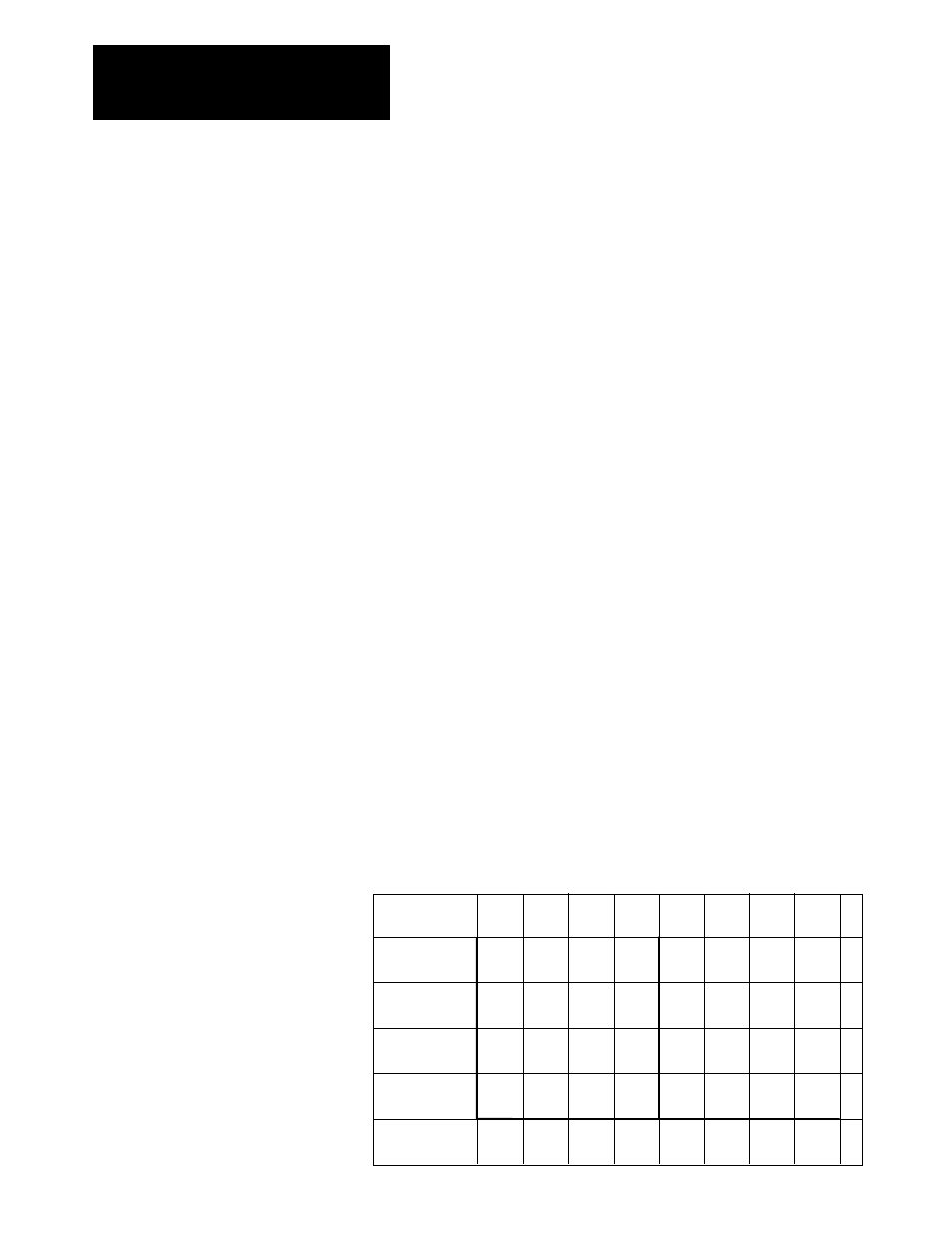

7. Run the drive at the lowest speed required for the application. Monitor

drive output current (Parameter 2 ) and record its value along the zero

axis on the graph below.

•

Decrease then increase the run boost value set in Step 5 from –4 to

+4V in 1V increments.

•

Monitor and record drive output current (Parameter 2) at each setting

in the graph below.

•

To allow the motor to run cooler, set the final run boost value

(Parameter 83) to the value that produces the lowest current.

75%

Drive Output Current

25%

Drive Output Current

50%

Drive Output Current

100%

Drive Output Current

-4V

-3V

-2V

-1V

Run Boost

Value

from

Step 5

+1V

+2V

+3V

+4V

0 Axis