Rockwell Automation 442L SC300 Safety Sensor User Manual User Manual

Page 19

Rockwell Automation Publication 10000202762 Ver 00 - January 2012

17

Chapter 4

Mounting

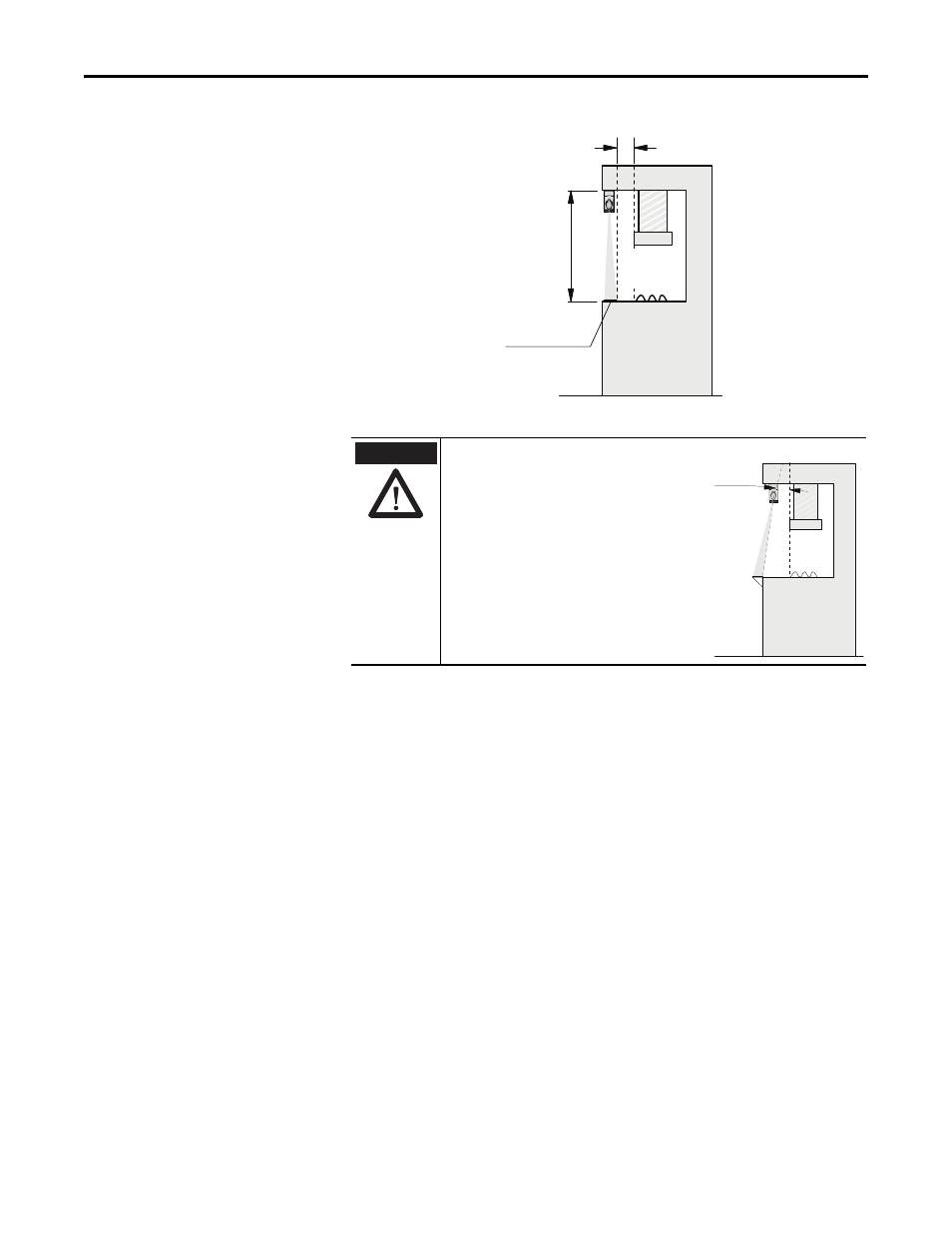

Figure 9 - Safety distance from the hazardous point

Safety distance according to prEN ISO 13

855 and EN ISO 13 857

The safety distance as defined in prEN ISO 13 855 and EN ISO 13 857 depends on:

•

Stopping/run-down time of the machine or system

(The stopping/run-down time is shown in the machine documentation or must be

determined by taking a measurement.)

•

Response time of the entire protective device (SC300: 20 ms)

•

Reach or approach speed

•

Other parameters that are stipulated by the standard depending on the application

How to calculate the minimum safety distance S according to prEN ISO 13 855 and

EN ISO 13 857:

Note

The following calculation shows an example calculation of the safety distance. The

calculation is based on the assumption that the approach is perpendicular to the

protective field.

Depending on the application and the ambient conditions, a different calculation may be

necessary.

Initial formula: S = K × T + 8 × (d – 14)

Where …

S =

Safety distance in [mm]

Hazardous

point

Safety distance S (D

s

)

Protective field

height

All-round

reflective tape

S (D s)

Ensure the necessary safety distance

between the access point and the

hazardous point is met at all parts of the

protective field at an angle.

Note that different rules may apply to

the calculation of the safety distance

for protective fields at an angle.

Your Rockwell Automation

distributor/sales office will be pleased

to assist you with the implementation

of special applications.

If the protective field is at an angle, pay special attention to the

safety distance.

ATTENTION