Control and signal wiring – Rockwell Automation 23C PowerFlex 400 AC Drive Packages for Fan & Pump Apps User Manual

Page 15

Rockwell Automation Publication 23C-IN001B-EN-P - June 2013

15

Main Input Disconnect Package (Style A/M)

Chapter 1

Control and Signal Wiring

Refer to the PowerFlex 400 User Manual for additional detailed information

about control and signal wiring.

The Control I/O Terminal Block (TB1) and Relay Terminal Block (TB2)

located on the drive Main Control Board provide terminals for interfacing

customer supplied control inputs and outputs. All analog and discrete control

wiring will be made at these terminals. Typical customer control and signal wiring

is shown on the Interconnect Drawings

on page

and

on page

To connect control and signal wiring to the drive package:

❏

1. Wire the control and signal leads by routing them according to the drive

option type. Note that you must punch openings in the option cabinet of

the desired conduit size, following NEC and all applicable local codes and

standards. I/O terminal block specifications are listed in

.

Control and signal wires should be separated from power wires by at least

0.3 meters (1 foot).

❏

2. Connect the control and signal wiring to the I/O terminals located on the

drive.

❏

3. Tighten the I/O terminals to the proper torque according to drive type as

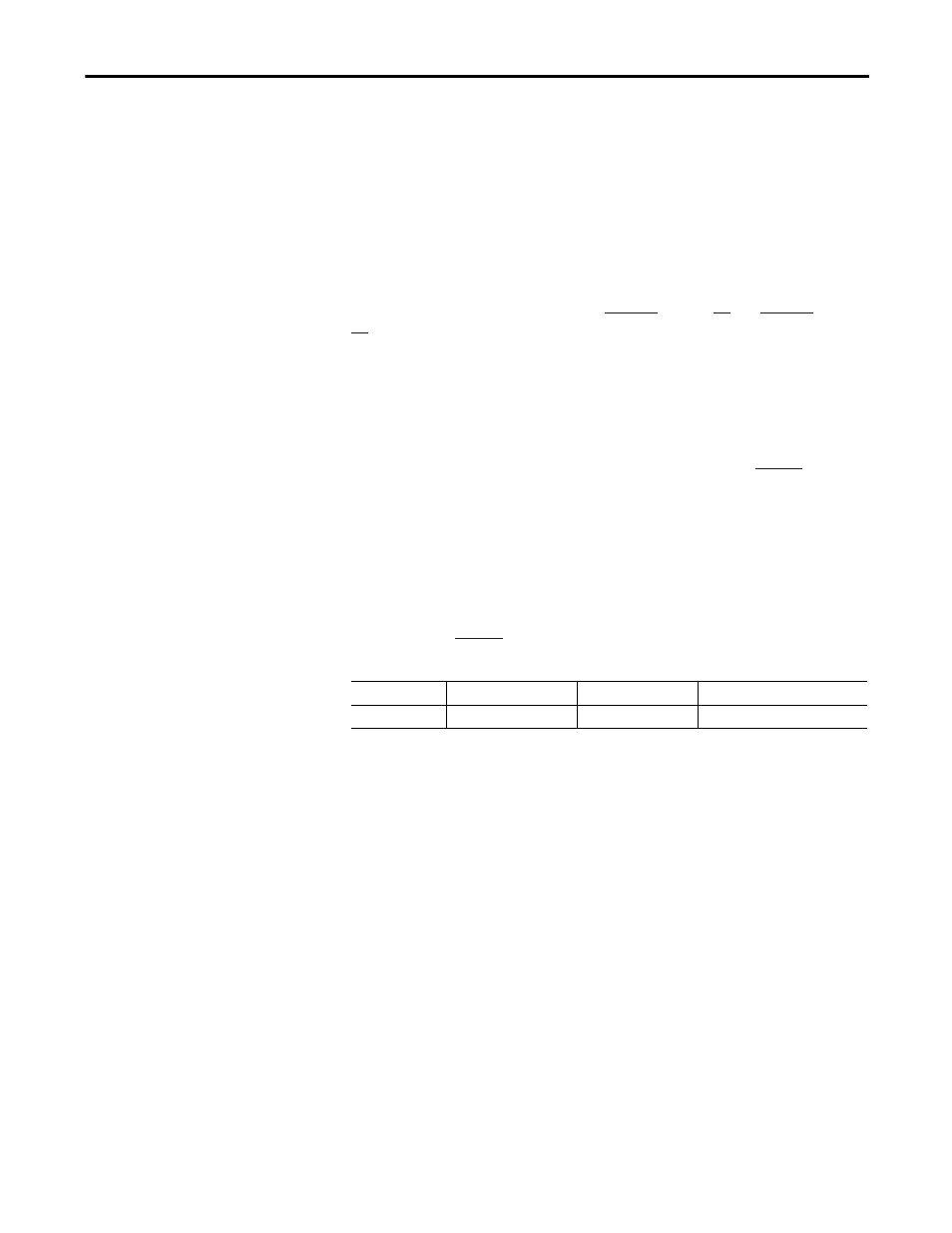

Table 4 - I/O Terminal Block Specifications

Voltage Rating

Maximum Wire Size

(1)

(1) Maximum/minimum sizes that the terminal block will accept - these are not recommendations.

Minimum Wire Size

Torque

208…460V AC

1.3 mm

2

(16 AWG)

0.13 mm

2

(26 AWG)

0.5…0.8 N•m (4.4…7 lb•in)