Component details, General precautions – Rockwell Automation 20L-LL PowerFlex 700L Liquid-to-Liquid Heat Exchanger User Manual

Page 9

Overview

P-3

PowerFlex 700L Liquid-to-Liquid Heat Exchanger User Manual

Component Details

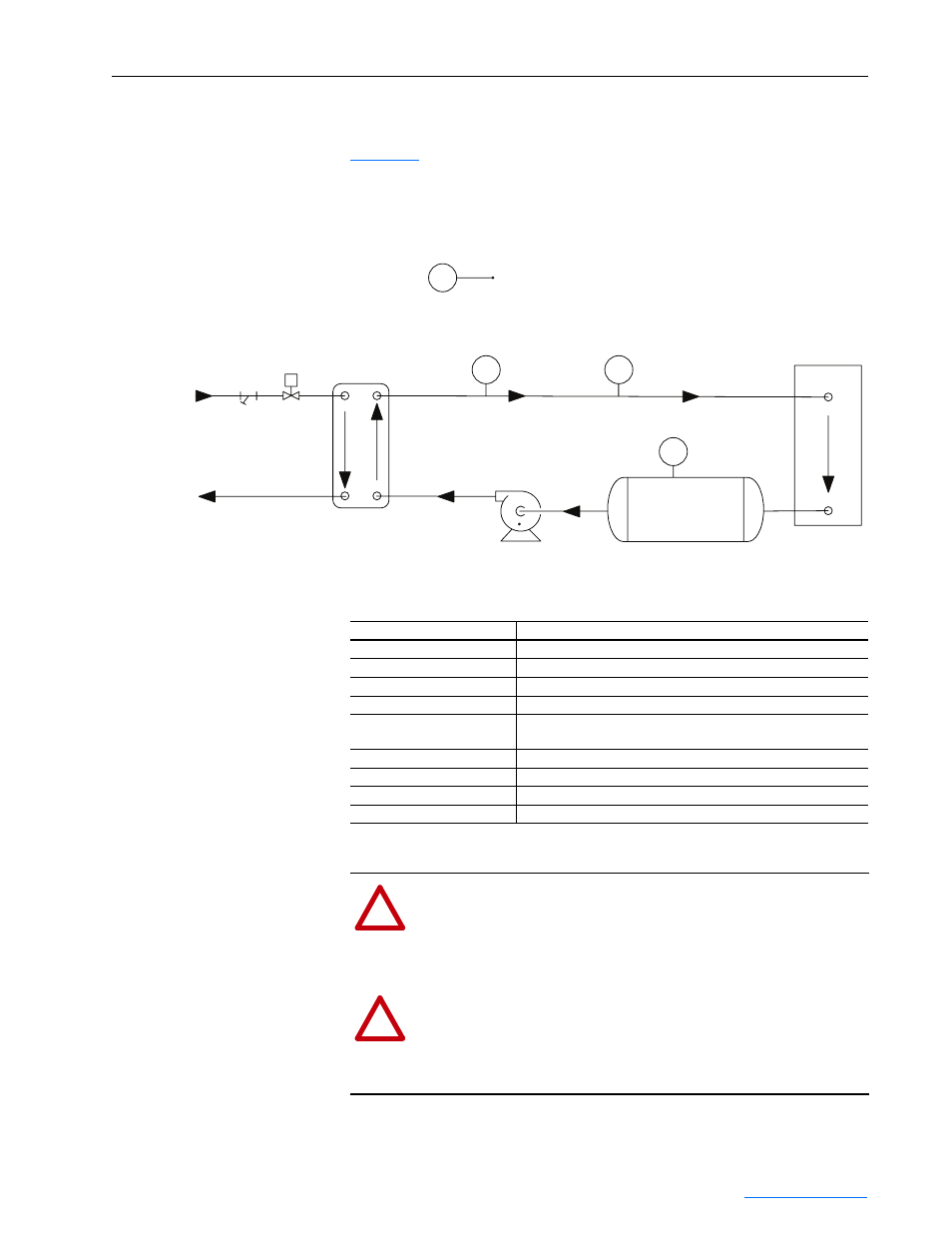

shows a cooling loop diagram for a typical liquid-to-liquid heat

exchanger.

Figure P.3 Liquid-to-Liquid Heat Exchanger Plumbing Diagram

The main components of the cooling loop include:

General Precautions

Ambient Sensor

Heat Exchanger

Pump

Reservoir

Drive

IN

OUT

IN

OUT

OUT

IN

Drive Coolant Temp.

Control

Valve

Strainer

Supply

Process

Water

Flow Switch

Level Switch

TE

TE

FS

LS

Part Description

Strainer

Filters particles from the supply water.

Control Valve

Controls the supply loop water flow.

Heat Exchanger Plate

Transfers heat from the drive loop to the supply loop.

Ambient Sensor

Senses the ambient temperature used for the dew point control.

Drive Coolant Temperature

Sensor

Senses the drive coolant temperature used for the dew point control.

Drive Coolant Flow Switch

Measures the drive coolant flow rate.

Level Switch

Senses the level of coolant in the reservoir.

Reservoir

Stores drive coolant.

Pump and Motor

Circulates drive coolant.

!

ATTENTION: An incorrectly applied or installed heat exchanger

can result in component damage or a reduction in product life.

Wiring or application errors, such as, undersizing the heat

exchanger, incorrect or inadequate AC supply, or excessive

ambient temperatures may result in malfunction of the system.

!

ATTENTION: Only qualified personnel familiar with adjustable

frequency AC drives and associated machinery should plan or

implement the installation, start-up, and subsequent maintenance

of the system. Failure to comply may result in personal injury and/

or equipment damage.