Upply loop for maintenance, see, Draining supply – Rockwell Automation 20L-LL PowerFlex 700L Liquid-to-Liquid Heat Exchanger User Manual

Page 30

2-4

Operation

PowerFlex 700L Liquid-to-Liquid Heat Exchanger User Manual

9. Entrapped air must be removed for the heat exchanger to function

properly. Remove the fill tube cap and depress the PRIME SWITCH for

2-3 minutes.

10. Replace and tighten the fill tube cap on the tank.

11. Reinstall the top and side covers on the heat exchanger. The

recommended tightening torque is 0.9 N-m (8 in-lbs.).

Draining Supply Side

Cooling Loop for Periodic

Maintenance

1. Shut off flow to the “IN FROM SUPPLY” connection of the cooling

loop.

2. Place a 5 gallon container under the pipe marked “SUPPLY DRAIN”

on the front of the heat exchanger (

3. Use a 9/16 inch or adjustable wrench to remove the plug from the

“SUPPLY DRAIN” pipe. (There is no need to use a backup wrench on

the pipe nipple.)

4. Allow the fluid to drain.

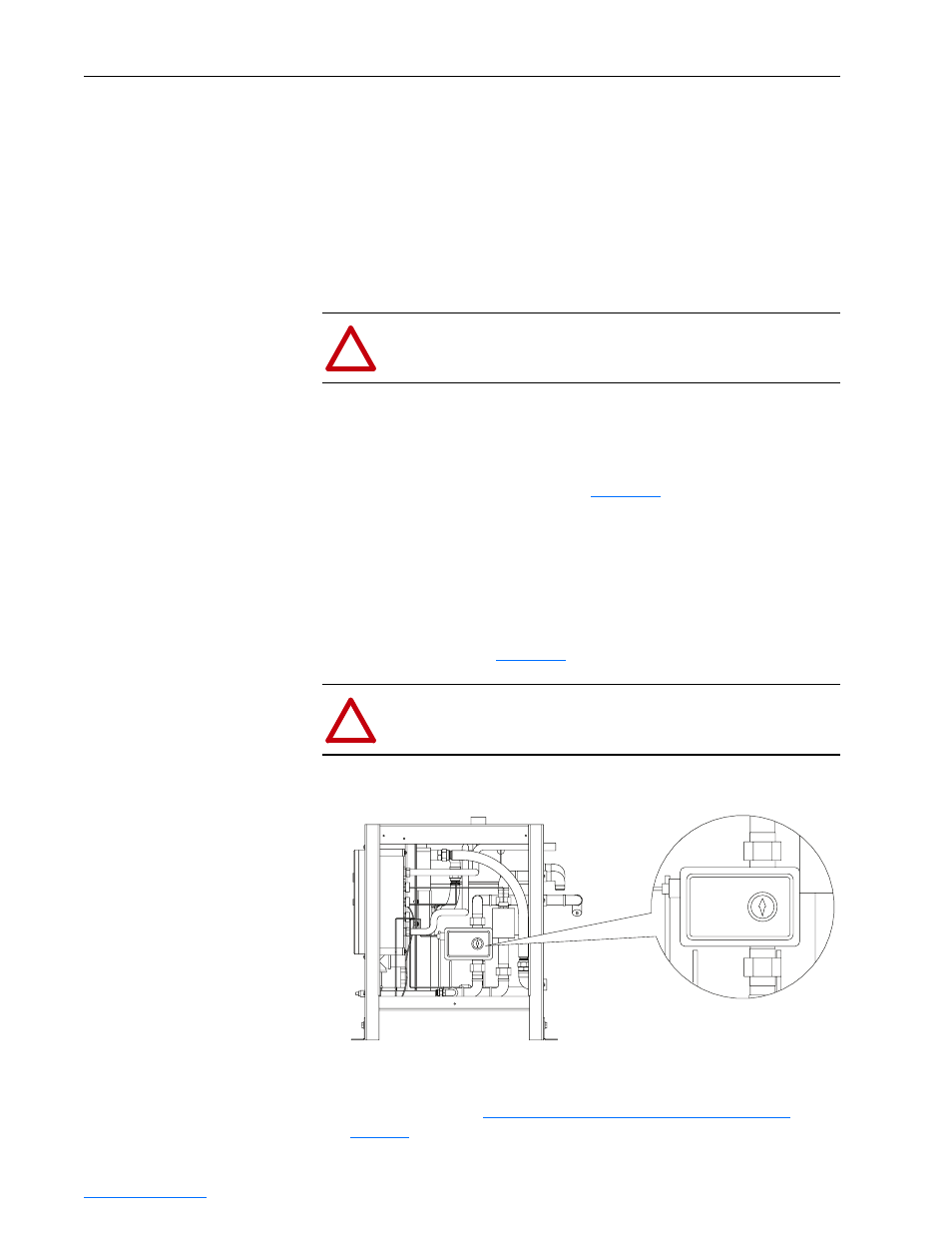

5. After flow stops, push the PRIME SWITCH for 8 seconds to open the

motorized valve (see

Figure 2.2

).

Figure 2.2 Supply Loop Motorized Valve Open Indication

6. Disconnect the hoses on the rear of the heat exchanger marked “IN

FROM SUPPLY” and “RETURN TO SUPPLY” using the tools and

method outlined in

Connecting Hoses to the Heat Exchanger on

. Place the ends of the hoses in a container to drain.

!

ATTENTION: Risk of equipment damage exists. It is

recommended to drain the supply side before draining the drive

side to avoid any possible damage to the pump.

!

ATTENTION: Risk of equipment damage exists. Pressing the

PRIME SWITCH longer than 20 seconds may damage the pump

if the drive loop is already drained.