Adding coolant to the drive loop for start-up, Adding coolant to the drive loop for start-up -3, Adding coolant to the drive loop for – Rockwell Automation 20L-LL PowerFlex 700L Liquid-to-Liquid Heat Exchanger User Manual

Page 29: Figure 2.1

Operation

2-3

PowerFlex 700L Liquid-to-Liquid Heat Exchanger User Manual

Adding Coolant to the Drive

Loop for Start-Up

1. Make sure all hose connections are completed as described in

Loop (from Heat Exchanger to Drive) on page 1-6

.

2. With the top and side covers removed from the heat exchanger, make

sure all wiring to the heat exchanger is completed as described in

and

, respectively.

3. Make sure both pipe plugs are tightened on the drains in front of the

heat exchanger.

4. Remove the fill tube cap from the top of the tank.

5. Fill the heat exchanger until the sight glass reaches the fill line with

approved coolant (see

Drive Coolant Requirements on page 1-3

).

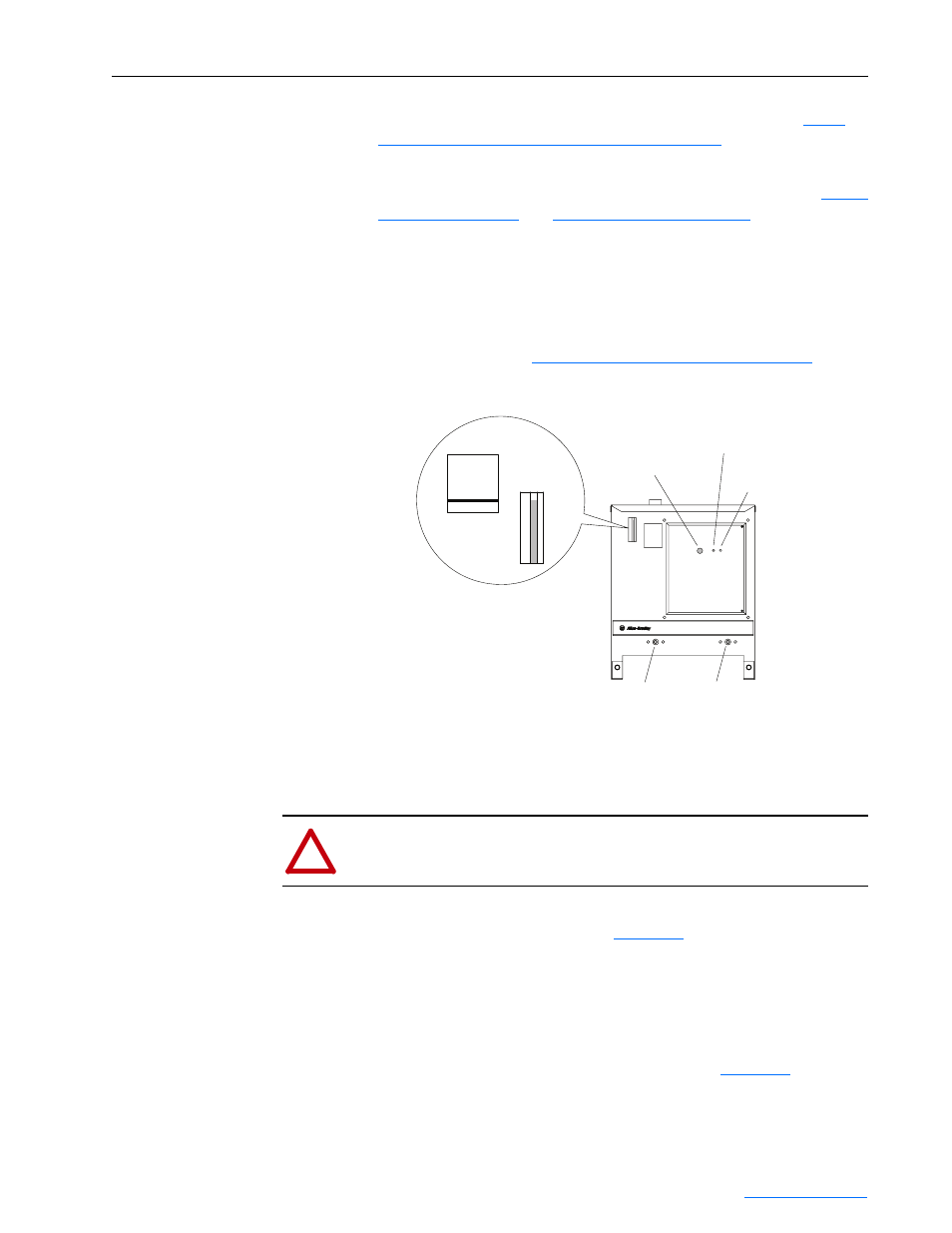

Figure 2.1 Fill Line, PRIME SWITCH, and Indicators

6. Loosely install the fill tube cap back on the tank to allow air to escape

the system while priming. Use caution as some coolant may splash out

of the tank.

7. While viewing the fluid level gauge on the front of the heat exchanger,

turn on the PRIME SWITCH (see

). Fluid level will decrease

rapidly. When the tank level lowers to about ¼ full, turn off the PRIME

SWITCH.

8. Repeat steps 5 through 8 until the tank remains at the fill line. (The

drive loop system typically holds up to 5 gallons, depending on length

of hoses.) If the tank is not filled to the fill line, an alarm may occur —

indicated by a flashing amber STATUS indicator (

).

FLUID

LEVEL

PRIME

SWITCH

STATUS

Indicator

POWER

Indicator

SUPPLY

DRAIN

DRIVE

DRAIN

!

ATTENTION: In Step 8 the fluid level in the tank will decrease rapidly. It

is important to not let the tank empty. Running the heat exchanger without

enough coolant may damage the unit and void the warranty.