Control wiring, Control wiring -12 – Rockwell Automation 20L-LL PowerFlex 700L Liquid-to-Liquid Heat Exchanger User Manual

Page 22

1-12

Installation

PowerFlex 700L Liquid-to-Liquid Heat Exchanger User Manual

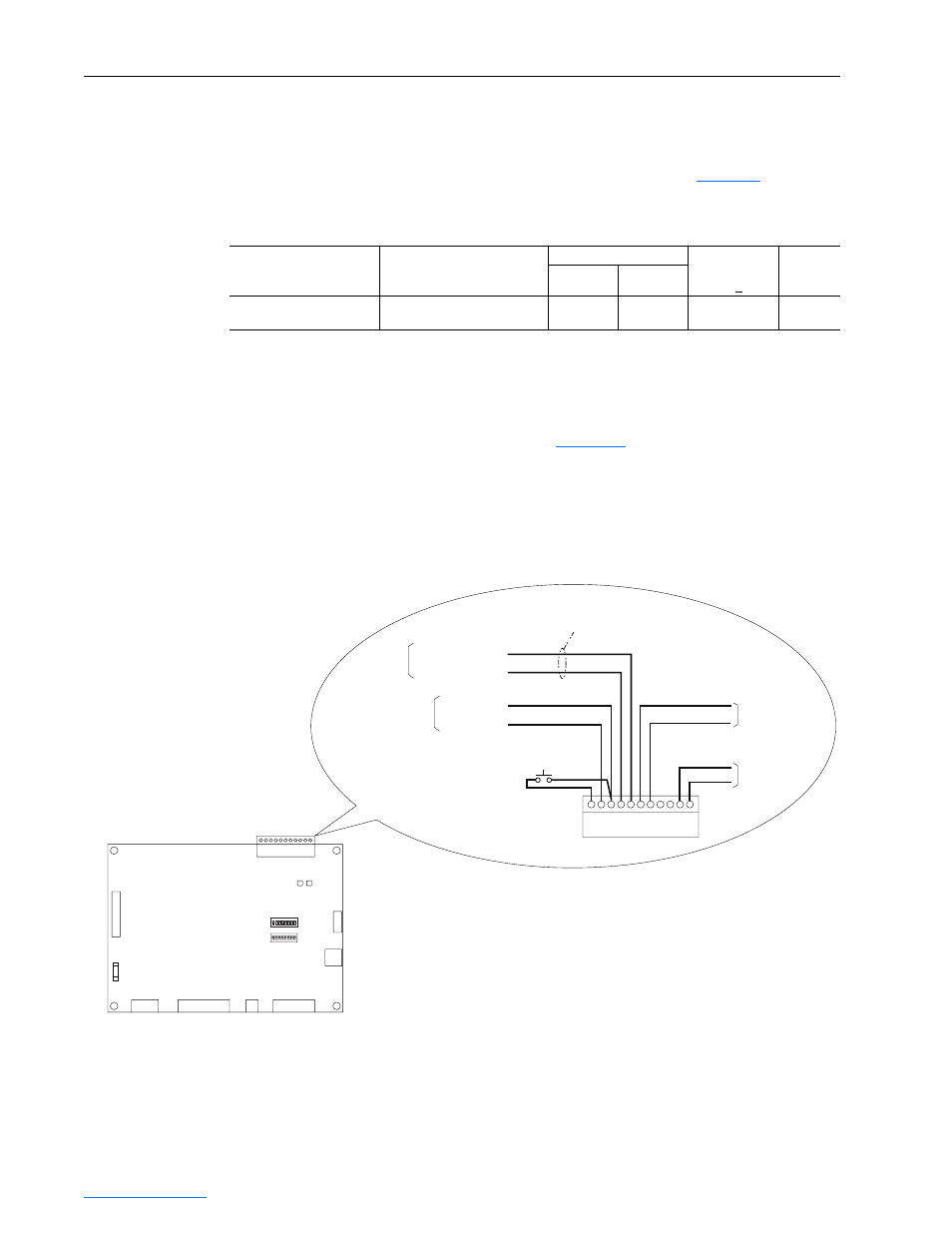

Control Wiring

Connect “run” and “interlock” control wiring from the PowerFlex 700L

drive to the J1 connector on the control board. Refer to

terminal specifications.

Table 1.F Control Board Terminal Specifications

Run Wiring

The run output signal from the PowerFlex 700L drive must be connected to

the heat exchanger control board (

) so that the heat exchanger

automatically starts when the drive is started.

The heat exchanger J1 connector provides fault and alarm contact outputs to

monitor the operating state of the heat exchanger if desired.

Figure 1.9 Control Run Wiring

Name

Description

Wire Size Range

(1)

Recommended

Tightening

Torque (+10%)

Wire Strip

Length

Maximum

Minimum

Coolant Controller Control

Wiring Terminal Block — J1

Control wiring for run, fault and

alarm (optional), and interlock

3.3 mm

2

(#12 AWG)

0.2 mm

2

(#24 AWG)

0.55 N-m

(5 lb.-in.)

7 mm

(0.3 in.)

(1)

Maximum/minimum sizes that the terminals will accept - these are not recommendations.

J2

J1

J3

S1

Heat Exchanger

Control Board

S2

J4

J8

J7

J6

J5

FU1

1

9

1

5

1

2

3

4

5

6

7

8

9

10

1

10

1

8

11

1

2

3

4

5

6

7

8

9

10

11

12V Common

120 VAC

PRIME SWITCH

(on electrical box cover)

+12 VDC

Run

Neutral

To Converter TB5-1

To Converter TB5-3

Frame

3A/3B

Drive

To TB1 (1b-5)

To TB1 (1b-6)

Frame 2

Drive

N.O.

Com

Alarm Contact

(30 VDC @

10A Max.)

N.C.

Com

Fault Contact

(30 VDC @

10A Max.)

J1