Power wiring, Power wiring -10 – Rockwell Automation 20L-LL PowerFlex 700L Liquid-to-Liquid Heat Exchanger User Manual

Page 20

1-10

Installation

PowerFlex 700L Liquid-to-Liquid Heat Exchanger User Manual

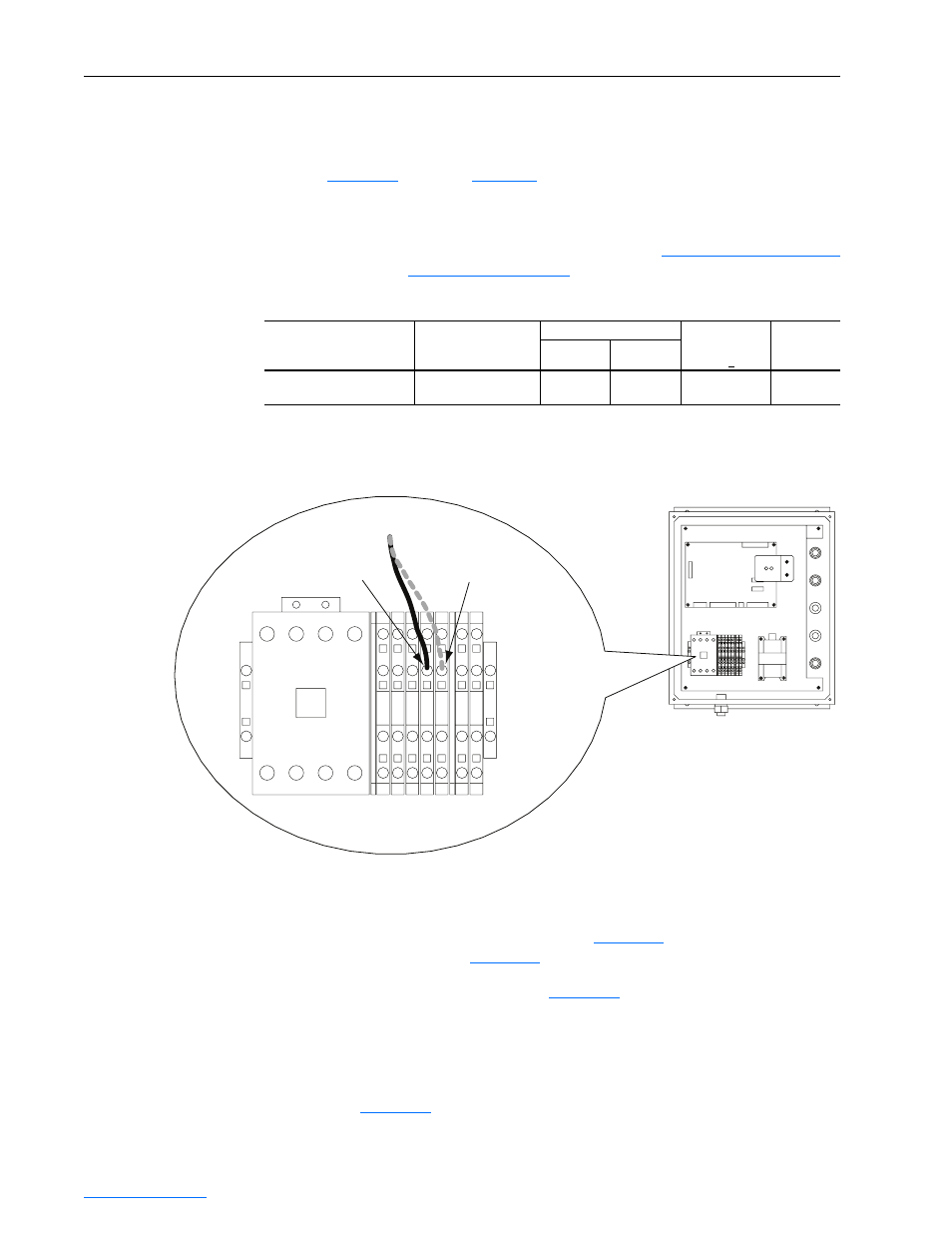

Power Wiring

Connect line power to the power terminal block’s L1, N, and PE terminals

(

Figure 1.6

). Refer to

Table 1.E

for power terminal specifications.

Important: The heat exchanger is configured and shipped for 120 VAC

operation. However, its configuration can be changed to

operate on 230 VAC. For details, see

.

Table 1.E Power Terminal Specifications

Figure 1.6 Power Terminal Block Electrical Connections

Configuring for 230 VAC Operation

1. Open the cover of the electrical box (

Figure 1.1

) and set the J2 jumper on

the control board (

Figure 1.7

) to the 230 VAC position (terminals 1-7).

2. On the power terminal block (

Figure 1.6

), disconnect wire #3 from

terminal H2 and reconnect it to terminal H4 for 230 VAC operation.

3. Remove the heat exchanger’s top panel first and then its left side panel to

access the pump motor conduit box. Remove the conduit box cover and

change the motor winding connections for 230 VAC operation as shown

in

Name

Description

Wire Size Range

(1)

Recommended

Tightening

Torque (+10%)

Wire Strip

Length

Maximum

Minimum

Input Power Terminals —

PE, N, and L1

Input AC line power

3.3 mm

2

(#12 AWG)

0.05 mm

2

(#30 AWG)

N/A

(Spring-Loaded)

10 mm

(0.4 in.)

(1)

Maximum/minimum sizes that the terminals will accept - these are not recommendations.

J2

J1

J5

J6

J7

J8

L1

N

H1

H2

H4

PE

PE

Wire #3

(115 VAC Line

Power Connection)

Wire #3

(230 VAC Line

Power Connection)