Removing top and side panels, Removing top and side panels -8 – Rockwell Automation 20L-LL PowerFlex 700L Liquid-to-Liquid Heat Exchanger User Manual

Page 18

1-8

Installation

PowerFlex 700L Liquid-to-Liquid Heat Exchanger User Manual

pressure drop of 5.00 to 6.00 PSI on the supply side, and flow must be

provided per

Table 1.D

.

Connect the two supply loop hoses from the heat exchanger to the supply

source.

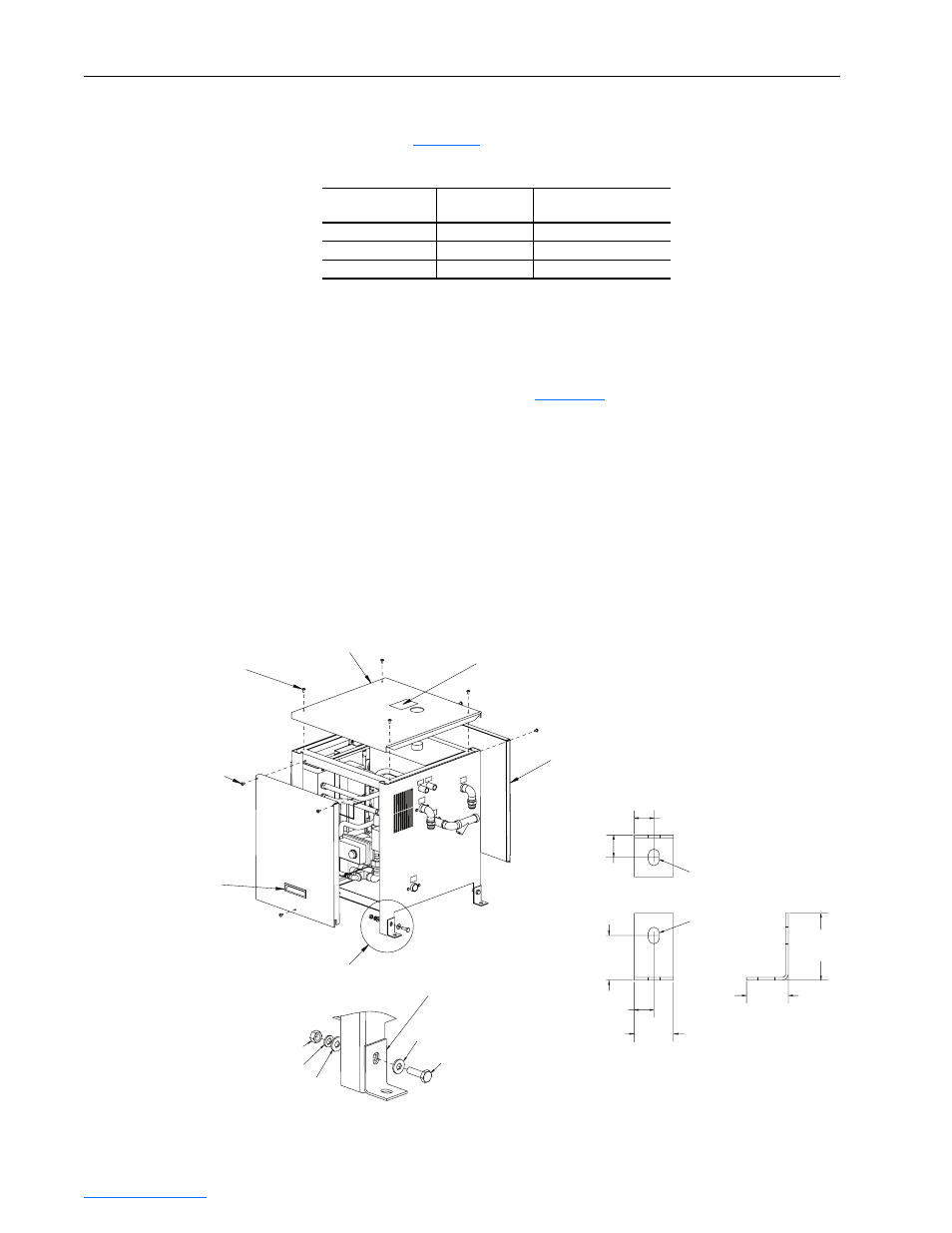

Removing Top and Side

Panels

The top panel and side panels (

Figure 1.5

) can be removed from the heat

exchanger to access internal components. To do so, proceed in this order:

1. Remove the fill tube cap from the top of the tank.

2. Remove the top panel by loosening four captive hardware screws.

3. Remove each side panel by unfastening/removing two sheet metal

screws and loosening one captive hardware screw. Then use the flush

handle to lift the side panel up and out.

Figure 1.5 Top and Side Panel Removal

Table 1.D Supply Loop Minimum Flow Rates

Heat Exchanger

Drive Size

Minimum Supply Loop

Flow Rate

20L-LL13K-P75A

Frame 2

15.1 LPM (4 GPM)

20L-LL13K-P75A

Frame 3A

22.7 LPM (6 GPM)

20L-LL24K-1P0A

Frame 3B

56.8 LPM (15 GPM)

FILL TUBE WARNING:

Fill with approved fluid or

equipment damage may result.

See Instruction Manual.

M10 x 1.5 x 35

Hexagonal Head Screw

M10 x 1.5 Nut

See DETAIL A

Top Panel

Flush Handle

(2 places)

Sheet Metal Screw

(4 places)

Side Panel

(2 places)

25.4

(1.0)

50.8

(2.0)

22.2

(0.88)

44.5

(1.75)

47.6

(1.88)

76.2

(3.0)

22.2

(0.88)

22.2 x 12.7

(0.875 x 0.5) Slot

22.2 x 12.7

(0.875 x 0.5) Slot

M10 Lock Washer

M10 Flat Washer

M10 Flat Washer

Shipping/Field Installation

Mounting Angle (4 places)

DETAIL A

Captive Hardware

(6 Places)

Dimensions are in

millimeters and (inches).