Lifting instructions, Lifting instructions -2 – Rockwell Automation 20L-LL PowerFlex 700L Liquid-to-Liquid Heat Exchanger User Manual

Page 12

1-2

Installation

PowerFlex 700L Liquid-to-Liquid Heat Exchanger User Manual

Lifting Instructions

The heat exchanger can be lifted off the shipping skid by removing the

packing material from the unit and unscrewing the mounting brackets lag

screws from the skid.

Using a Lift Truck

Forks a can be inserted between the exchanger legs from the front or sides

as long as the forks extend beyond the opposite surface. Note: Bottom

sections of the exchanger are open.

Using Rigging Straps

Rigging straps should be placed under the unit and along the sides to lift

from the top. These straps should be long enough to provide fill tube

clearance on the top.

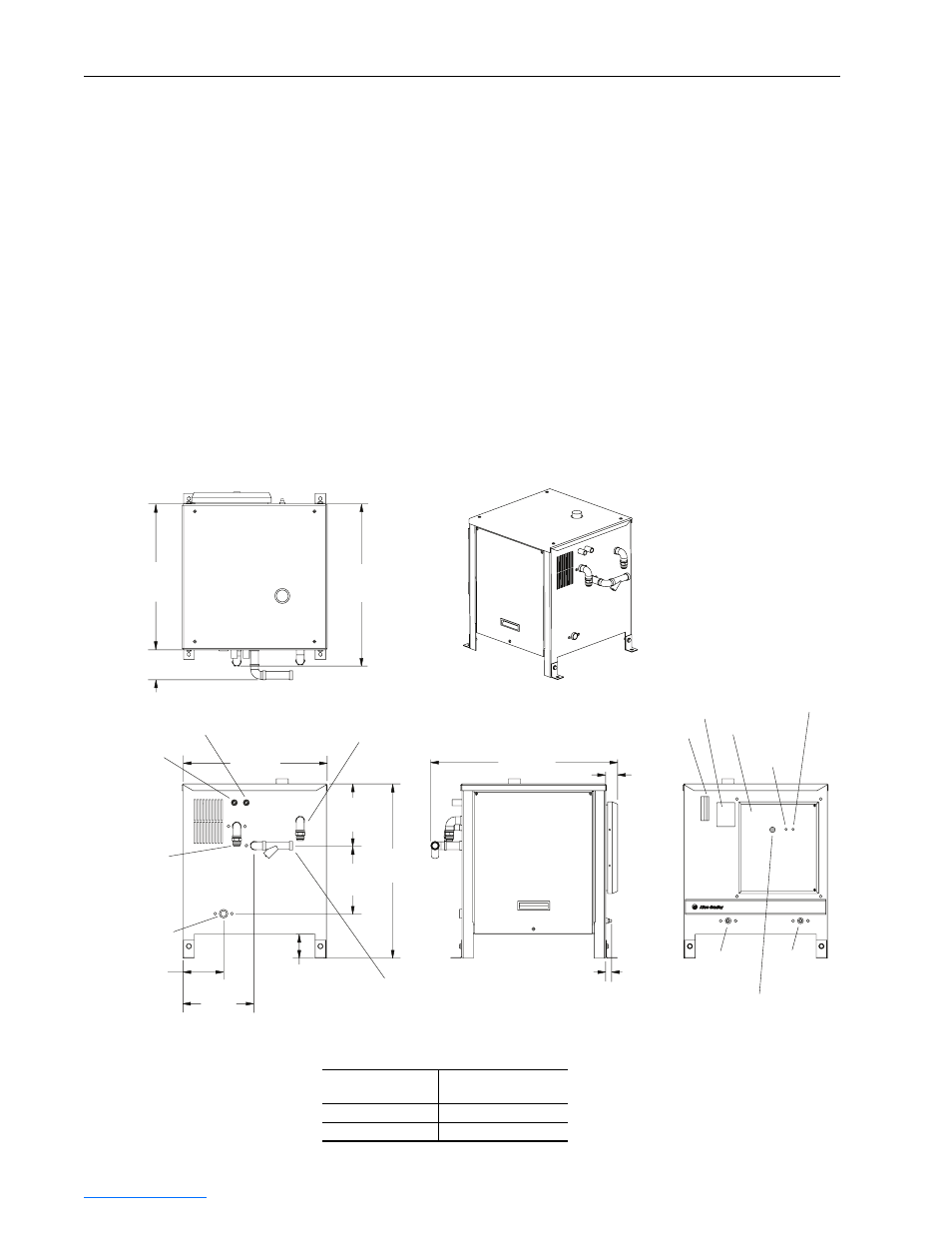

Figure 1.1 Heat Exchanger Dimensions and Coolant Connections

619 Max.

(24.4)

127 Max.

(5.0)

616 Max.

(24.3)

TOP

REAR

FRONT

688 Max.

(27.1)

FILL TUBE

CONTROL

WIRING

POWER

TO DRIVE

INLET

RETURN TO

SUPPLY

102 Min.

(4.0)

172

(6.8)

304

(12.0)

258

(10.18)

289

(11.38)

740 Max.

(29.1)

31 Max.

(1.25)

38

+0.25/

-0.00

(1.5)

781 Max.

(30.77)

INLET FROM SUPPLY

(Strainer shipped loose)

SUPPLY

DRAIN

DRIVE

DRAIN

FROM DRIVE OUTLET

Fluid Level

Data

Nameplate

Electrical

Box

STATUS

Indicator

POWER

Indicator

PRIME SWITCH

Dimensions are in

millimeters and (inches).

Heat Exchanger

Approximate Weight

Empty (no coolant)

20L-LL13K-P75A

113 kg (250 lbs.)

20L-LL24K-1P0A

113 kg (250 lbs.)