MacDon PW7 Pick-Up Header User Manual

Page 72

SECTION 7 – SERVICE

Form 169149

Revision E

66

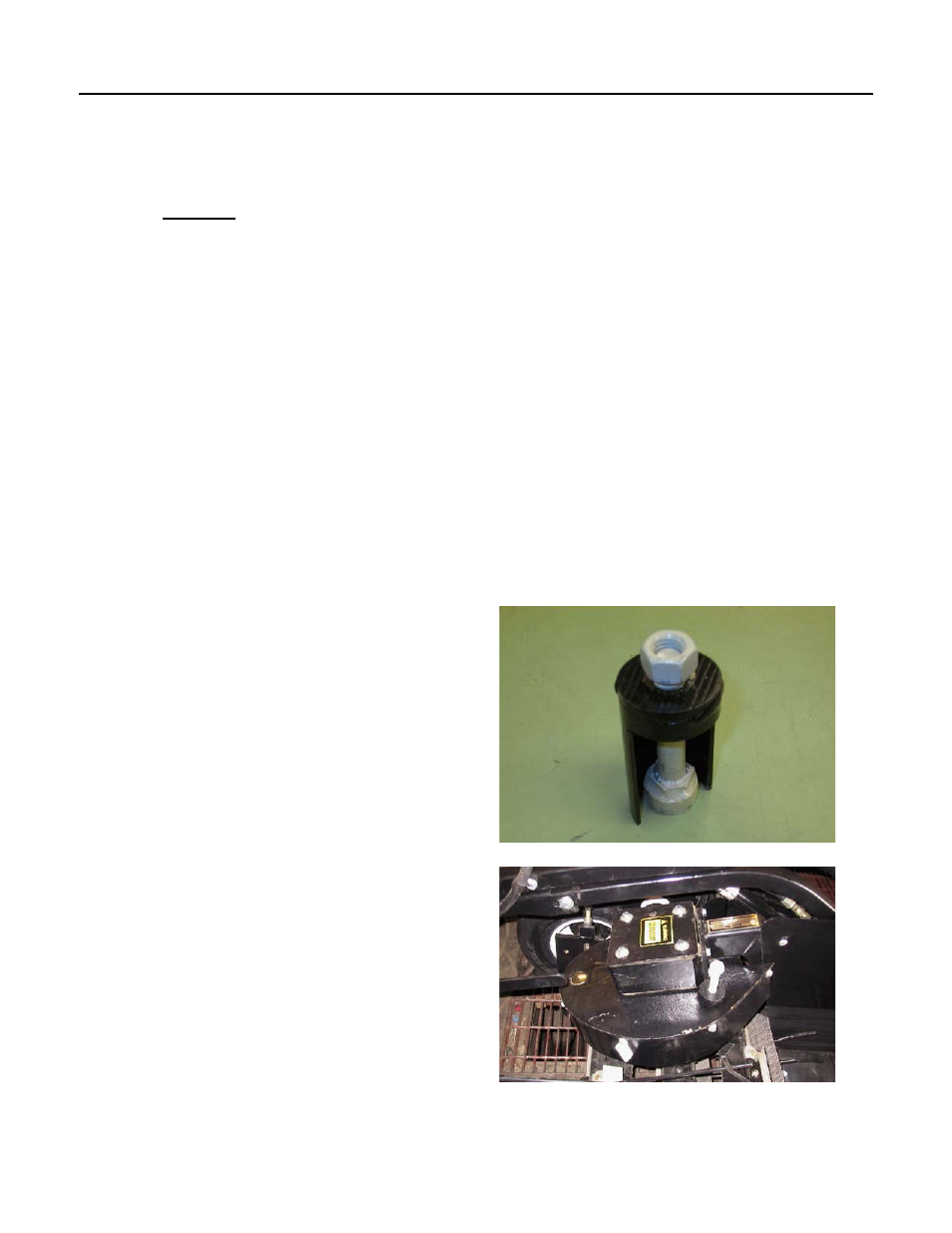

e) Place the longer shaft of the gearbox through

the drive end rotor and attach the special

gearbox puller to the shaft.

NOTE:

DO NOT pull the shaft through

completely or the follower arm will not be

able to be installed. Follow step (f).

Attempting to drive the gearbox out for arm

installation may result in gearbox damage.

f) Pull the shaft approximately 1 inch in.

Remove the puller.

g) Install the follower arm and key onto the

shaft of the small gearbox. Orient the

follower arm offset toward the scroll plate.

h) Apply permanent thread locking compound

and tighten the 7/8-inch jam nut. The 7/8-

inch jam nut will pull the gearbox into its

permanent position.

i) Install and tighten the 3/8-inch x 1 1/2 inch

bolt, and lock nut on the follower arm.

j) Rotate the drive end rotor until the follower

arm on the new gearbox is centered in the

small hole in the scroll plate.

k) Install the flat washer, two bearings, shoulder

bolt, spring lock washer and nut to the

follower arm. See drawing for proper

orientation.

l) Install the scroll plate plug.

m) Install the finger bar and apply permanent

thread locking compound to the 5/16-inch x

1-inch bolts that are used to secure the finger

bar to the finger bar idler arm. Snug the bolts

to the finger bar arms.

n) Rotate by hand the drive end rotor one

complete revolution. This is to ensure that

the finger bars are seated properly.

o) Tighten the four remaining finger arm

bolts.

p) Install the scroll plate guard.

q) Install the drive belt.

r) Install the drive belt guard.

s) Check gearbox lubrication level. Add

NLGI Grade 000 extreme pressure,

semi-fluid lithium grease, such as

Mobilux EP 023, Petro-Can Precision

XL EP000, or Chevron Dura-Lith EP000

as required.

Follow steps (g-o) in removal procedure and

(a-p) in installation procedure for each

gearbox to be replaced.

NOTE: Occasionally during installation

of the gearboxes, the gears may bind.

However, after the 7/8-inch jam nuts have

been tightened, the gearbox will operate

correctly.

Special Tool Gearbox Puller - Part # 180784

Puller on Gearbox

P00081

P00082