MacDon PW7 Pick-Up Header User Manual

Page 31

SECTION 4 - ADJUSTMENTS

Form 169149

Revision E

25

6. Tighten the clamping bolt to lock into

place

7. Repeat steps 4 to 6 for the other side.

Match the LH and RH wheel height using

the cogs on the wheel plates.

8. Adjust suspension.

NOTE: When wheel height is changed,

suspension should be adjusted as well.

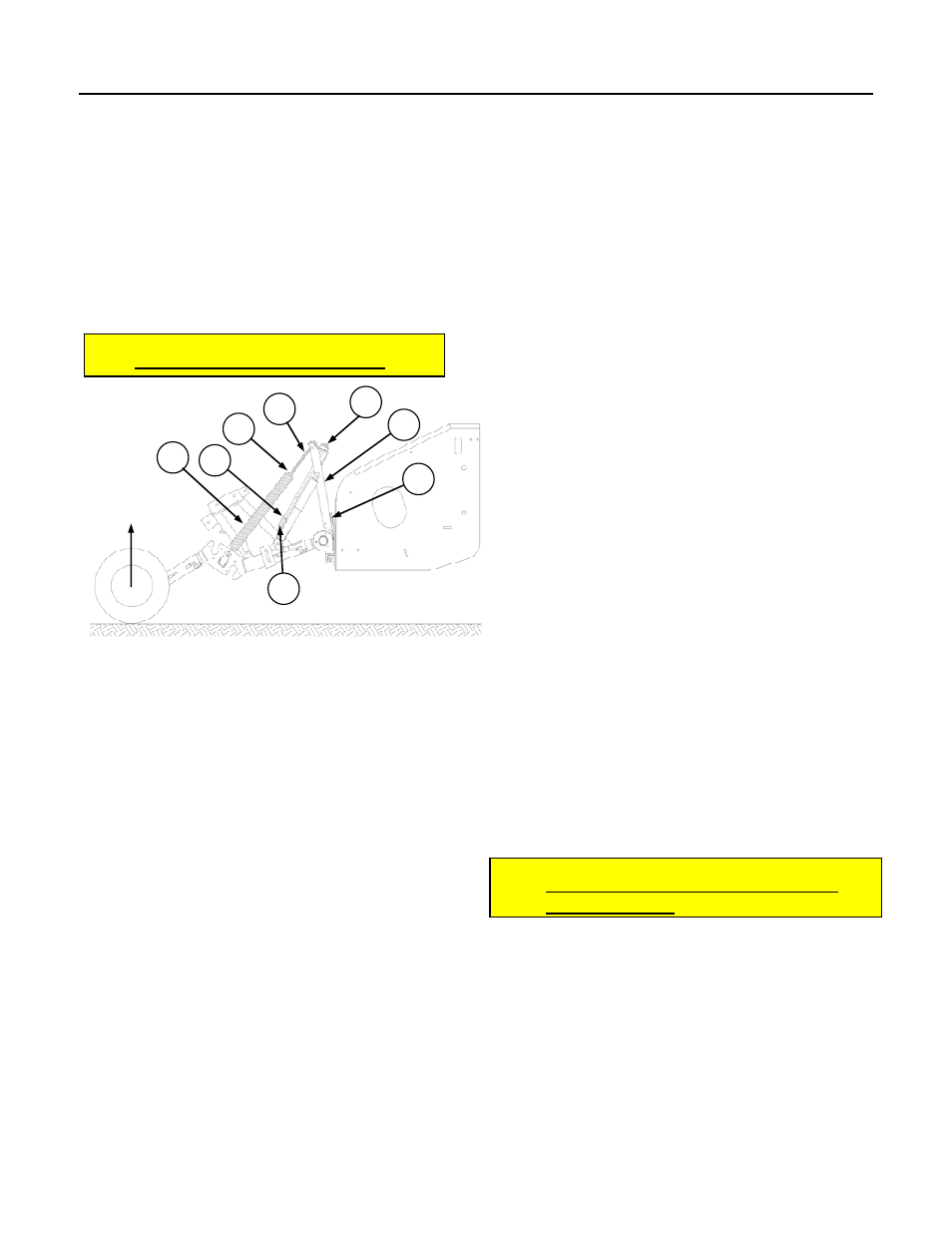

4.3 SUSPENSION ADJUSTMENT

Suspension System Assembly and Parts List

(Illustration May Differ)

1. Lifter Adjustment Bolt (w/rubber stoppers)

2. Spring Bolt

3. Spring Bolt Locking Nut

4. Lifter Adjustment Bolt Locking Nut

5. Spring

6. Lifter Bracket

7. Mounting Bracket Plate

8. Channel Upright

a) Adjust tooth/wheel height. See previous

page.

b) Lower header until wheels just touch the

ground. [Rear roller approximately 20

inches (508 mm) above the ground.]

c) Tighten the spring bolt (2) evenly on both

sides until the wheels begin to lift off the

ground. Turn the spring bolt clockwise to

lift the wheels and counter clockwise to

lower the wheels.

NOTE: The friction in the gas shock

absorbers must be compensated for by lifting

the wheels during tightening and allowing

them to fall to their normal resting position.

The height of the wheels should be checked in

this manner after every 1/2 inch (12mm) of

spring adjustment.

d) Tighten the spring bolt-locking nut (3)

against the spring casting to prevent

loosening.

e) Raise header so wheels are approximately 6

inches (150 mm) off the ground.

f) Lower storage brace into engaged (float

lockout) position and insert clevis pin (see

Section 3.4). If pin does not go in, adjust

lifter adjustment bolt (1) so clevis pin can be

easily installed and removed.

g) Jam the lifter adjustment bolt-locking nut (4)

against the lifter bracket (6).

Note: If ground speed is above 7 mph

(11 km/h) it may be necessary to back off the

float to prevent the header from bouncing

excessively.

Note: During field operation, the rear roller

shaft should be at 14 inches (350 mm) above

the ground.

4.4 SPRINGWIRE/FIBREGLASS

ROD

ADJUSTMENT

The spring wires and the fiberglass rods must be

set properly for different crop and conditions.

a) Remove the clevis and hitch pins and adjust

the spring wire tube so that the spring wires

protrude up through the fiberglass rods as

illustrated. This will protect the fiberglass

rods from becoming damaged by the spring

wire edges.

1

2

4

3

5

6

7

8

Wheels start

to lift off

ground