Caution – MacDon PW7 Pick-Up Header User Manual

Page 63

SECTION 7 – SERVICE

Form 169149

Revision E

57

Installing the 1/16-inch diameter hole

orifice will likely prevent the master

cylinder from lagging.

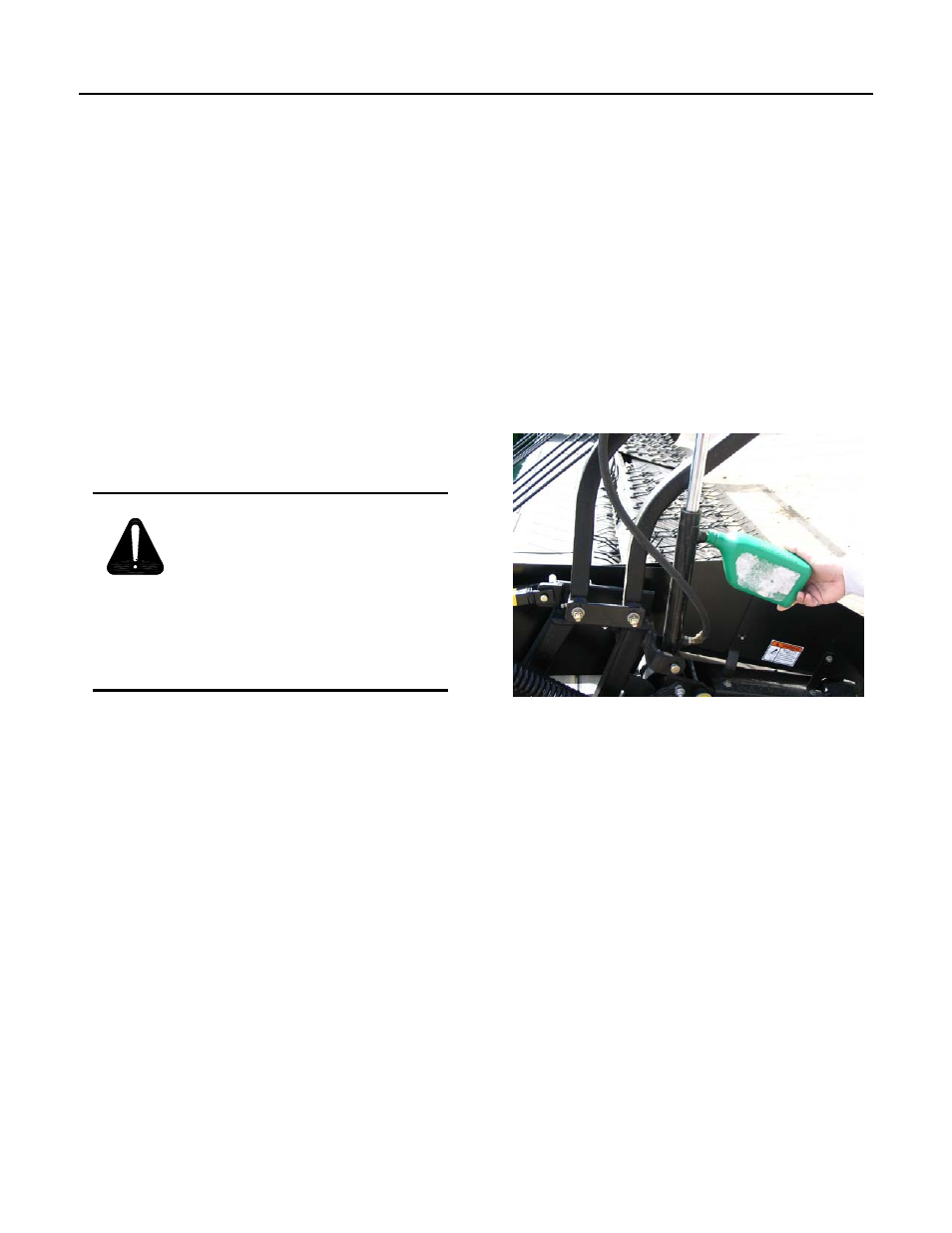

F) Bleeding the Hydraulics

In order for the hydraulics to perform

properly, all or most of the air must be

removed from the system. The following

procedure provides the easiest method of

bleeding the hydraulics. The hydraulics

should be bled after initial installation, if the

unit has sat for a significant period of time,

and if adjustments are needed to the

hydraulics.

CAUTION

: High-pressure

hydraulic oil can cause serious

injuries such as burns, cuts, and

tissue damage! Always take

precautions when working with hydraulic

oil. Wear safety goggles, gloves and thick

clothing. Seek immediate medical

attention if cut or burnt.

a) The hold down is controlled using the

reel lift control located in the combine

cab. Fully raise the hold down.

b) Engage the hold down safety locks.

Ensure that the lock is fully rotated over

center so that it will not slip forward.

c) Lower the hold down so that it comes to

rest on the safety locks. (This serves to

relieve the hydraulic pressure in the

lines).

d) Hold the plastic pail so the lip of the pail

is underneath the bleed plug and so that a

stream of oil shooting out of the plug will

go into the pail.

e) Loosen the small bleed screw on the end

of the bleed plug with a 1/4-inch wrench.

f) Have someone activate the hydraulics. The

hold down may lift slightly and a stream of

oil will come from the bleed screw.

g) Run oil from the bleed screw until it is a

steady clear stream. Have the operator stop

activating the hydraulics and tighten the

1/4inch bleed screw.

h) Fully raise the hold down again.

i) Disengage the safety locks.

j) Lower the hold down.

Bleeding of Hydraulics

P00696

P00696