Attention – MacDon PW7 Pick-Up Header User Manual

Page 44

SECTION 5 – OPERATING INSTRUCTIONS

Form 169149

Revision E

38

5.4

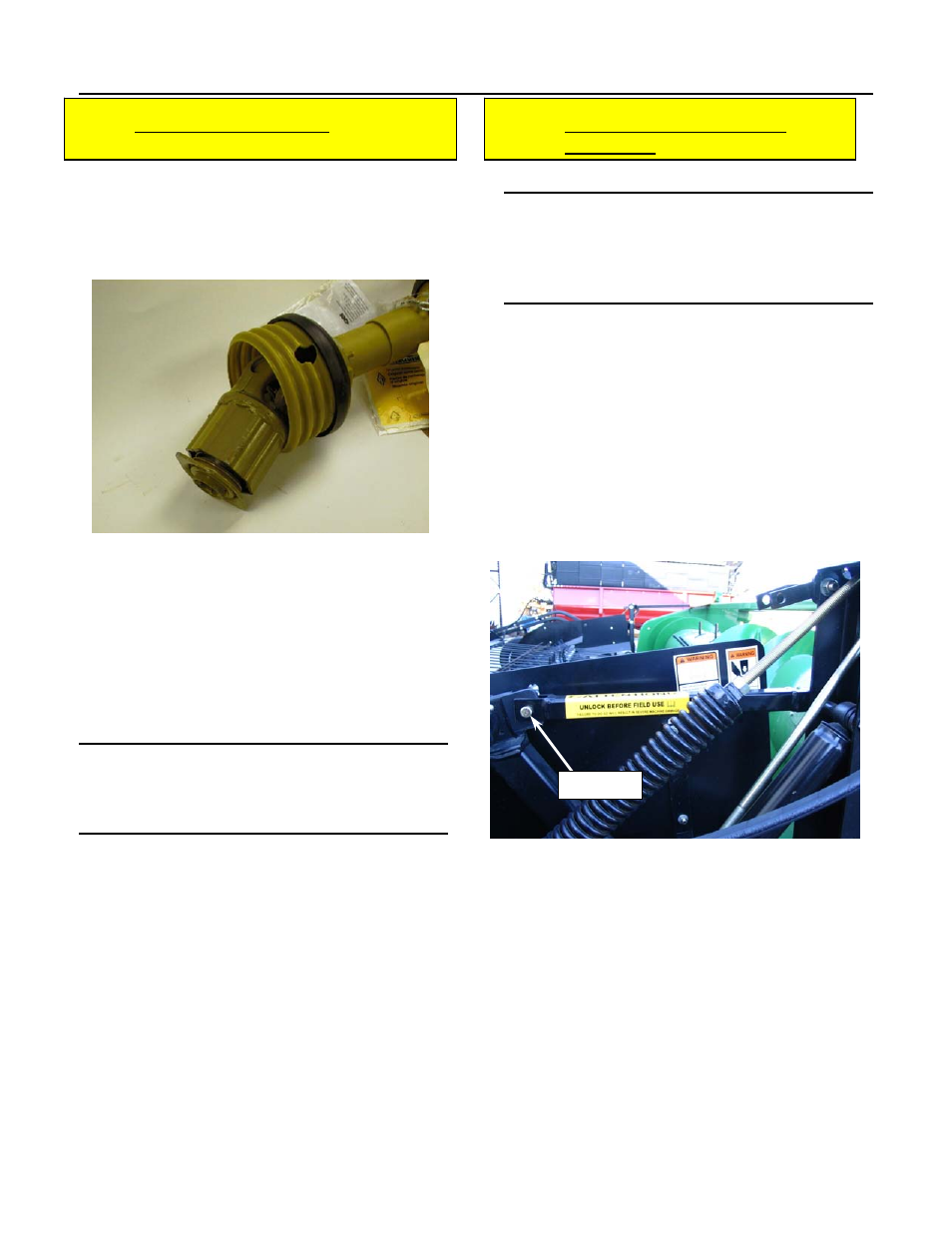

RADIAL PIN CLUTCH

(On all header drive shafts)

Every header is equipped with a driveshaft,

which contains a radial pin clutch. This clutch

emits a rattling sound and pulsating motion when

slippage occurs.

Radial Pin Clutch

The purpose of this clutch is to provide

protection against overload. When an obstruction

encounters the auger and creates an overload, the

clutch will slip notifying the operator of a

problem. Frequent slippage for more than two or

three seconds may result in clutch damage.

ATTENTION

: Prolonged operation of the

header with the clutch slipping will cause

damage to the header and/or clutch.

5.5

DISCONNECTING FROM

COMBINE

ATTENTION

: Always lock the storage

brace prior to disconnection. Failure to

lock storage braces will result in difficulty

reconnecting the header to the combine.

TIP: Engaged braces for long trips from

field to field on rough terrain will prevent

the pickup from bouncing.

a) Remove the clevis pins from storage

clevis.

b) Pull storage braces downward out of

storage brace holders and place in locking

position.

Storage Brace - Engaged

c) Reinstall the clevis pins in storage braces.

To ease pin installation it may be

necessary to slightly raise or push down

on pickup wheel.

d) Move unit to storage location.

e) Disconnect all hydraulics and wiring

between the header and combine. Some

combine models use a multi function

coupler that disconnects the hydraulics,

P00174

P00677

Clevis Pin