Maintenance – Multiquip WRS5200DFPU (KUBOTA WG972-GL-E3 DUAL FUEL) User Manual

Page 58

page 58 — wrs5200dfpu hYdrauLIC roLLer sCreed • operatIon manuaL — rev. #0 (08/18/14)

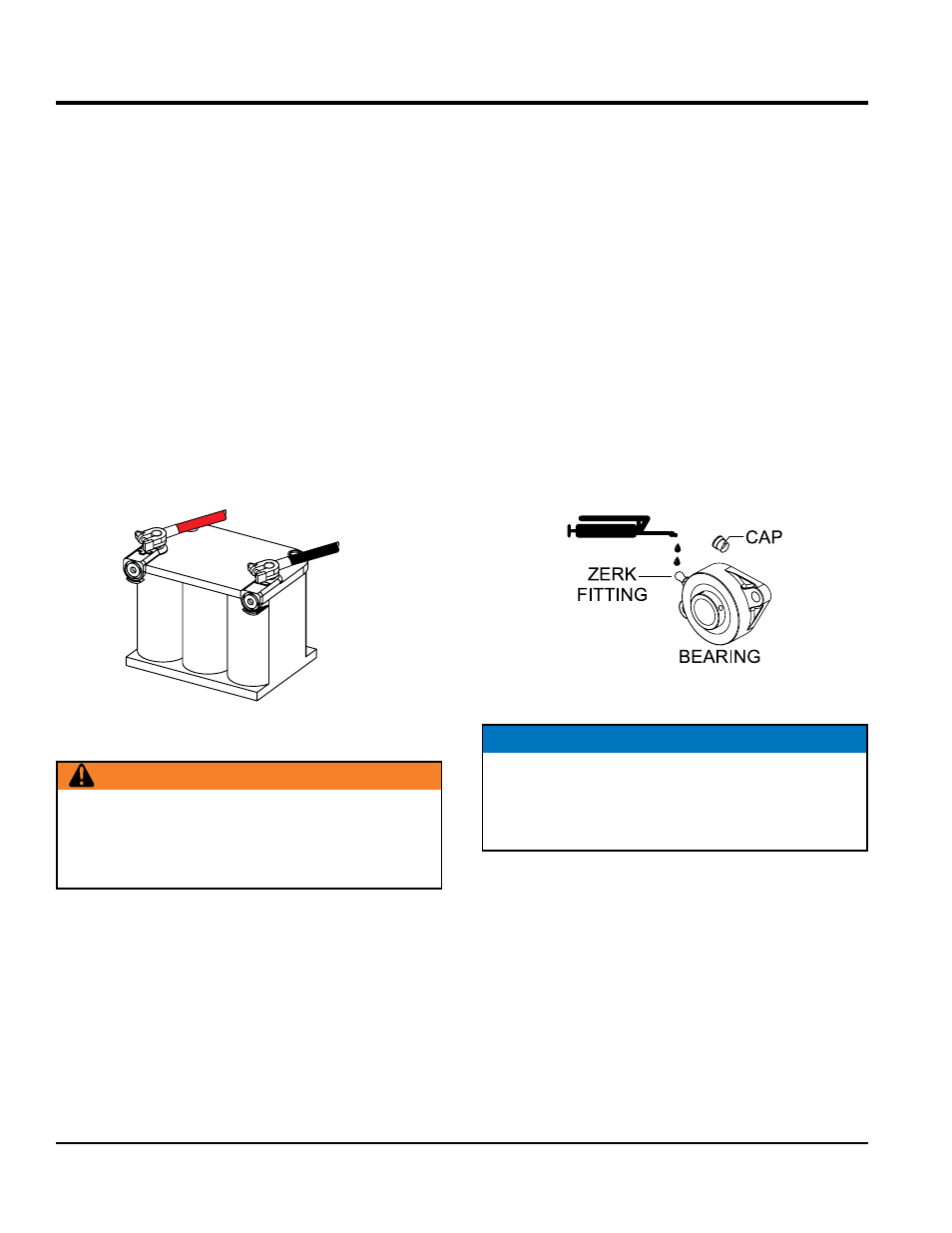

Mishandling of the battery shortens its service life and adds

to maintenance cost.

1. Check and clean battery terminals for corrosion.

2. The battery (Figure 59) used in the power unit is an

Absorbed Glass Mat. (AGM) type and is maintenance

free.

3. Never attempt to charge a battery that is frozen. The

battery can explode unless first allowed to thaw.

4.

ALWAYS be sure that the battery cables are properly

connected to the battery terminals as shown below.

Generally the

RED cable will be connected to the

positive terminal of the battery, and the

BLaCK cable

will be connected to the negative terminal of the battery.

See Figure 59.

Figure 59. Battery

5. Disconnect the negative terminal ( - ) of the battery

during storage. If unit will be stored where ambient

temperature will drop to -15° C or less, remove and

store battery in a warm, dry place.

NEGATIVE

(BLACK)

POSITIVE

(RED)

warnIng

If the battery cables are connected incorrectly, electrical

damage will occur causing damage to the roller's

electrical circuits. Pay close attention to the polarity of

the battery when connecting the battery.

maintenance

LPG System

Run the engine at idle speed and use a soap solution

or its equivalent to check all LPG connections for leaks

between the fuel tank and the dual fuel carburetor.

Bubbles will indicate a loose connection.

Always check that the fill up valve and liquid withdraw

valve on the LPG fuel tank can be opened and closed

easily.

Check that the hot water lines are not leaking

Check that the vacuum lock pipe is not damaged.

BearIng LuBrICatIon

Strike tube and drive tube bearings (Figure 60) require

lubrication daily. Lubricate all bearing zerk grease fittings

with EP3 grease or equivalent.

Figure 60. Zerk Fittings

NOTICE

Failure to lubricate bearing grease fittings daily will

cause rotation of drive and strike tubes to stiffen. To

prevent contamination of the bearing, always insert

cap onto zerk fitting.