Maintenance – Multiquip WRS5200DFPU (KUBOTA WG972-GL-E3 DUAL FUEL) User Manual

Page 54

page 54 — wrs5200dfpu hYdrauLIC roLLer sCreed • operatIon manuaL — rev. #0 (08/18/14)

maintenance

General maintenance practices are crucial to the

performance and longevity of your screed. This equipment

requires routine cleaning, truss sections inspection,

lubrication and V-belt inspection for wear and damage.

Reference (Table 4) and (Table 5) for scheduled engine

and screed maintenance.

The following procedures, devoted to maintenance, can

prevent serious screed damage or malfunctioning.

warnIng

Accidental starts can cause severe injury

or death.

ALWAYS place the ignition switch in the

OFF position before performing any

maintenance.

Disconnect negative battery cable from

battery before servicing.

ALWAYS allow the engine to cool

before servicing.

never attempt any

maintenance work on a hot (muffler,

radiator, etc.) power unit.

warnIng

Certain maintenance operations or machine

adjustments require specialized knowledge and skill.

Attempting to perform maintenance operations or

adjustments without the proper knowledge, skills or

training could result in equipment damage or injury to

personnel. If in doubt, consult your dealer.

warnIng

Some maintenance operations may

require the engine to be run. Ensure

that the maintenance area is well

ventilated. Gasoline engine exhaust

contains poisonous carbon monoxide

gas that can cause unconsciousness

and may result in

death

aIr fILter (daILY)

The gasoline/propane engine used with this screed is

equipped with a replaceable, high-density paper air filter

element.

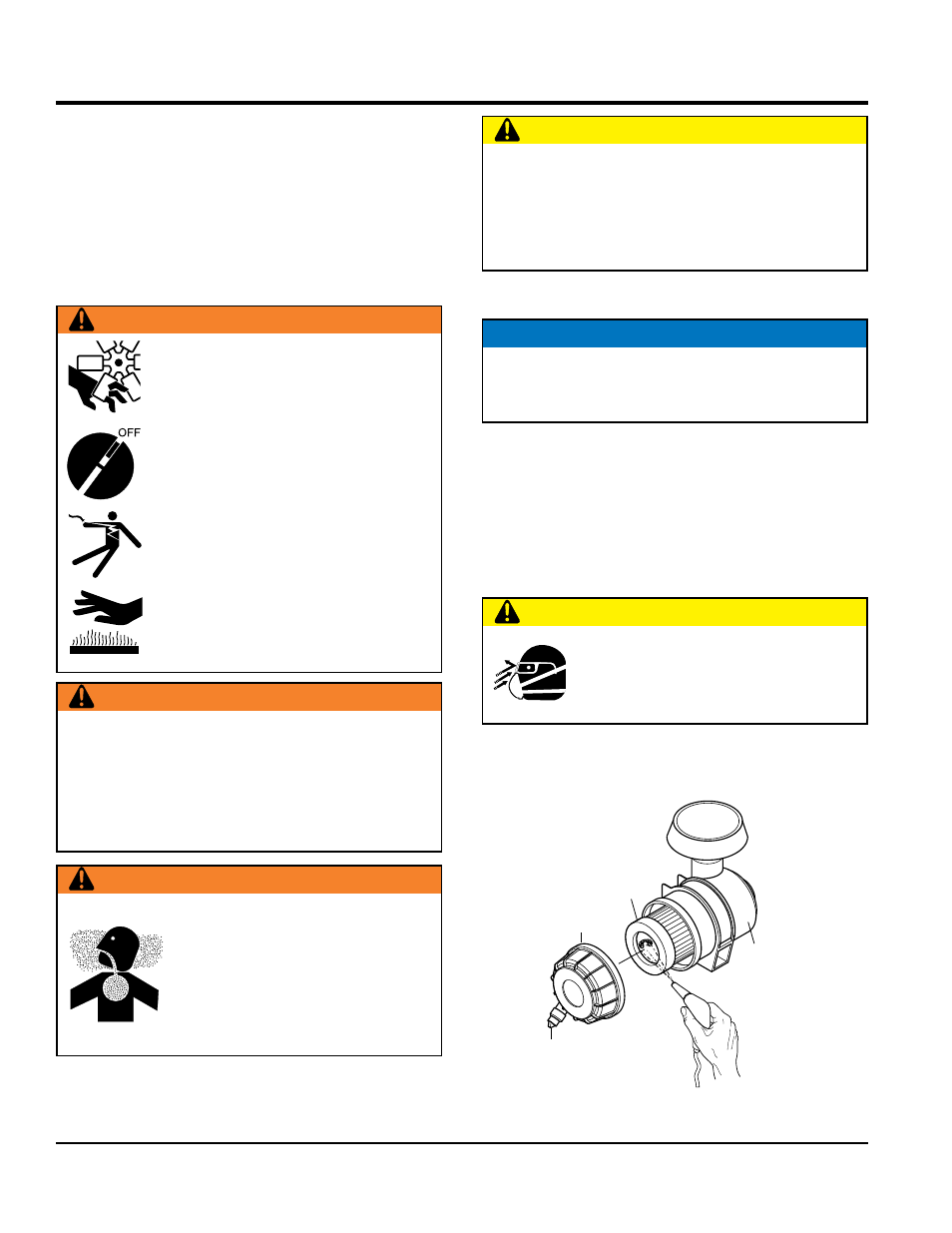

Check the air filter (Figure 51) daily or before starting the

engine. Check for and remove any heavy buildup of dirt and

debris along with loose or damaged components.

1. Unlock/release the clamps that secure the dust pan

cover to the body.

Figure 51. Air Filter Components

CautIon

ALWAYS disconnect the spark plug wire from the spark

plug and secure away from the engine before performing

maintenance or adjustments on the machine.

ALWAYS disconnect battery cables before attempting

any service or maintenance on screed.

NOTICE

Operating the engine with loose or damaged air filter

components could allow unfiltered air into the engine

causing premature wear and failure.

CautIon

Wear protective equipment such as

approved safety glasses or face shields

and dust masks or respirators when

cleaning air filters with compressed air.

PRIMARY

AIR FILTER

ELEMENT

BLOW COMPRESSED

AIR FROM THE

INSIDE OUT

DUST PAN

EVACUATOR

VALVE

BODY