Roller screed assembly – Multiquip WRS5200DFPU (KUBOTA WG972-GL-E3 DUAL FUEL) User Manual

Page 38

page 38 — wrs5200dfpu hYdrauLIC roLLer sCreed • operatIon manuaL — rev. #0 (08/18/14)

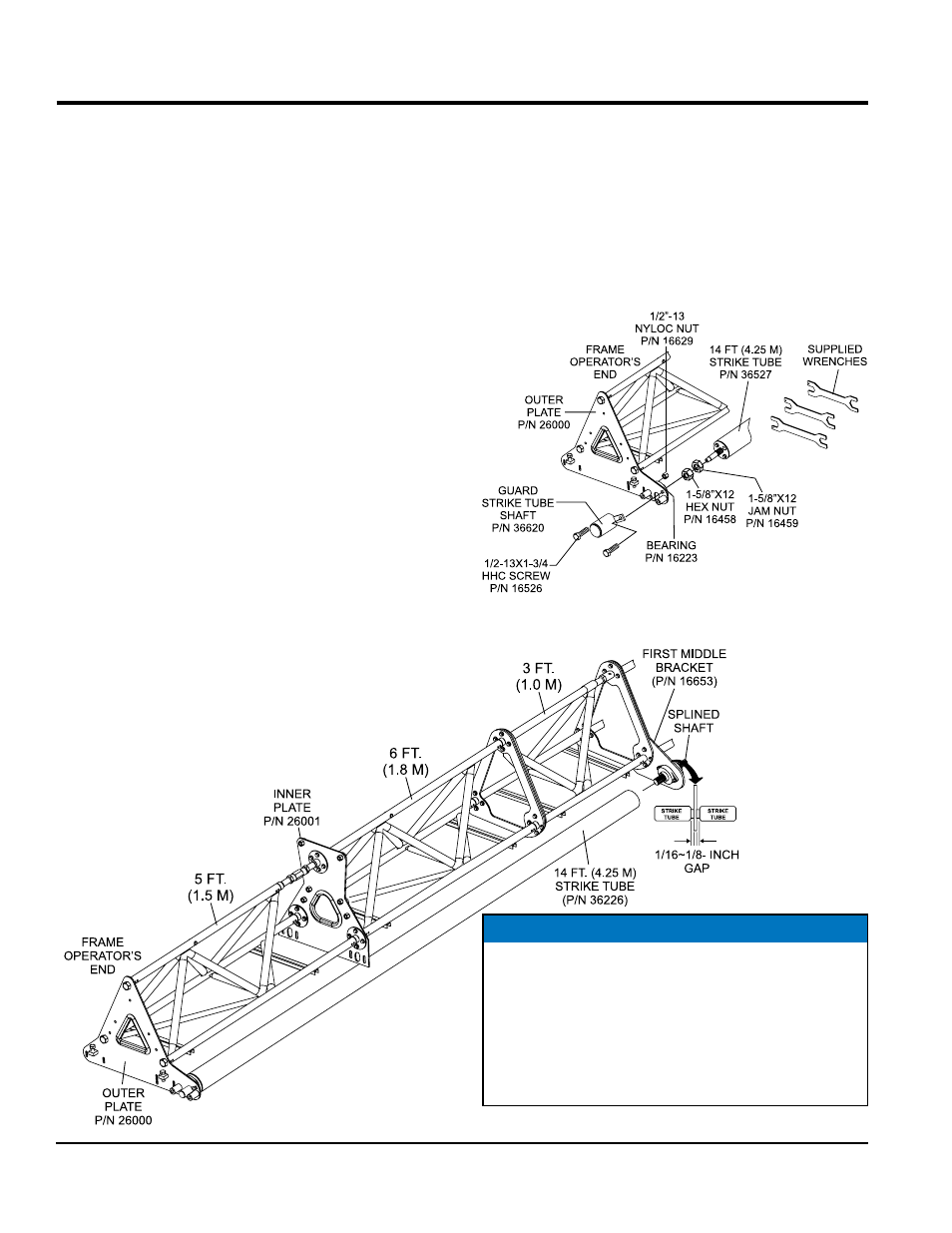

roller screeD assembly

task 7: strike tube assembly

The roller screed used in this example will require different

lengths of strike tubes. Two separate 14 ft. (4.25 meters)

sections and one 16 ft.(4.87 meters) section will be

required, yielding a combined length of 44 ft. (13.41 meters).

This following instructions will illustrate the installation of

the strike tubes onto the screed. The installation will begin

on the operator's side of the screed and will finish on the

engine side of the screed.

Strike Tube Installation (Operator's End)

1. Verify that bearing and strike tube guard (Figure 18)

have been mounted on the outer plate at operator's end

of screed. If either item is not installed please install.

2. Also, if installed remove the four 3/8-16X2 HHC screws

that secure the scraper bar assembly to the five foot

section of frame. Set scaper bar assembly aside.

3. Insert one end of the 14 ft. (4.25 meters) strike tube

shaft into the 1-3/8" bearing. Using the supplied

wrenches turn the 1-5/8" nut and jam nut until they

butt up against the strike tube hub. Tighten security.

Figure 18. Strike Tube Middle Bracket (Operator's End)

Strike Tube Installation (Middle Bracket)

1. Locate middle bracket, P/N 16653 (Figure 18) plate

on operator's end of screed. Make sure bearings (2)

and splined shaft has been mounted. If bearings and

shaft have not been installed, install as referenced in

Figure 17 (See task 4).

2. Insert other end of the 14 ft. (4.25 meters) strike tube

shaft into the splined shaft as shown in Figure 17.

Figure 17. Strike Tube (Operator's End)

NOTICE

The strike tube adjustment nut should be adjusted so

that the inner edge of the strike tube next to the middle

bracket is spaced between 1/16 to 1/8 inch. Please note

the strike tube will bottom out on the splined shaft when

a gap of less than 1/16 of an inch between the strike

tube and middle bracket remains. Further adjustment

will bend the outer plate.