Memmert IFP 400 - 800 Incubators (Generation 2003) User Manual

Page 42

PERFECT

page 42

21 Sterilisers

21.1 Purpose definition for MEMMERT hot air sterilisers

The oven SFP is intended for the sterilisation of medical materials by dry heat using hot air at atmospheric

pressure.

21.2 Notes in accordance with Medical Products Guidelines

For sterilisers in the context of the Law on Medical Products (MPG), the „Celsius“ software may only be

used for logging purposes, but not for the remote control (remote operation) of devices.

The product lifetime specified by the manufacturer is 8 years.

21.3 Guidelines for sterilisation in MEMMERT hot air sterilisers

For hot air sterilisation there are different regulations covering the temperature settings and the sterilisation

times, as well as the packaging of the products to be sterilised. The values to be selected depend on the

type and condition of the load to be sterilised and on the type of bacteria which have to be de-activated.

Please make yourself familiar with the sterilisation method laid down for your application before carrying

out sterilisation using your MEMMERT cabinet.

The operation of the MEMMERT hot air steriliser is also subject to the Standard DIN 58 947 Part 6.

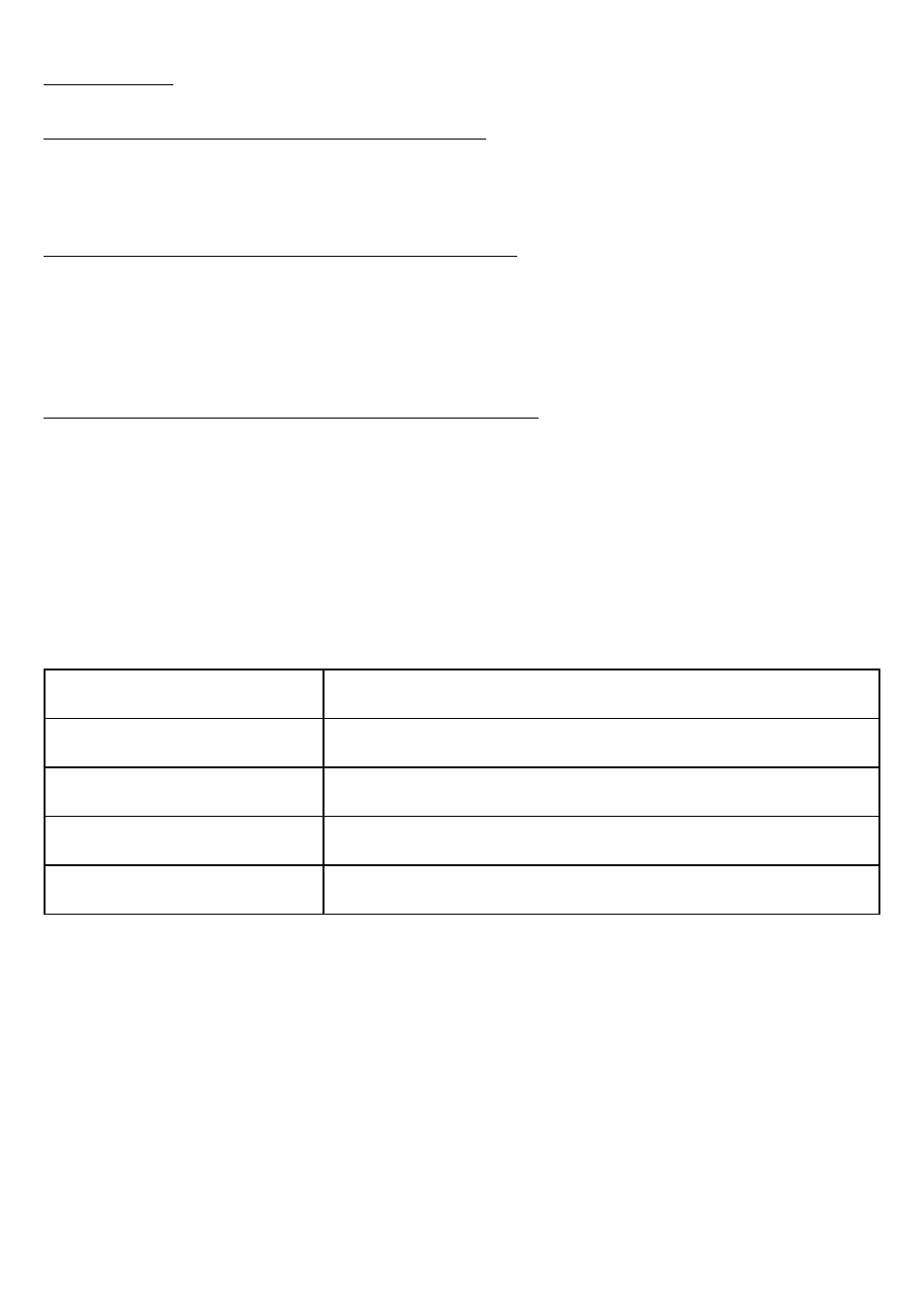

A few examples of the correct preparation for different medical products are summarised in the following

table:

Load

Preparation

Instruments (no soft solder)

load cleaned instruments, wrapped twice in aluminium foil or in

steriliser foil suitable for hot air (recommended)

Cutting instruments

load cleaned instruments, wrapped twice in aluminium foil or in

steriliser foil suitable for hot air (recommended)

Syringes (no plastics)

load plunger and cylinder separately, wrapped twice in aluminium

foil or in steriliser foil suitable for hot air (recommended)

Glass and glass instruments

dismantle cleaned glass vessels and all-glass syringes and place into

dishes, cool down slowly

FBottles, vessels and similar items must be sterilised without closure and with the opening downwards,

in order to avoid the formation of cold air pockets. The recommended sterilisation temperature is usually

180°C (German Pharmacopoeia DAB 10).

Sterlisation should in all cases be carried out as setpoint-dependent operation, according to the following

example. The holding time to be selected consists of the stabilisation time (i.e. the time until the desired

temperature has been established within the entire steriliser chamber), the actual sterilisation time, and a

safety margin.