6 profinet, Profinet, 4system description – Lenze Controller-based Automation User Manual

Page 43

Lenze · Controller-based Automation - Visualisation · System Manual · DMS 1.5 EN · 04/2014 · TD17

43

4

System description

4.3

Network topologies

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

4.3.6

PROFINET®

Visualisation applications with PROFINET are available for the following Lenze devices:

• HMI series EL 100

• Industrial PCs: EL 1800-9800, CS 5800-9800 and CPC 2800

The Industrial PCs use an OPC server for communication.

• Cabinet Controller 3231 C/3241 C (with an external monitor panel/display)

• Panel Controller p300/p500

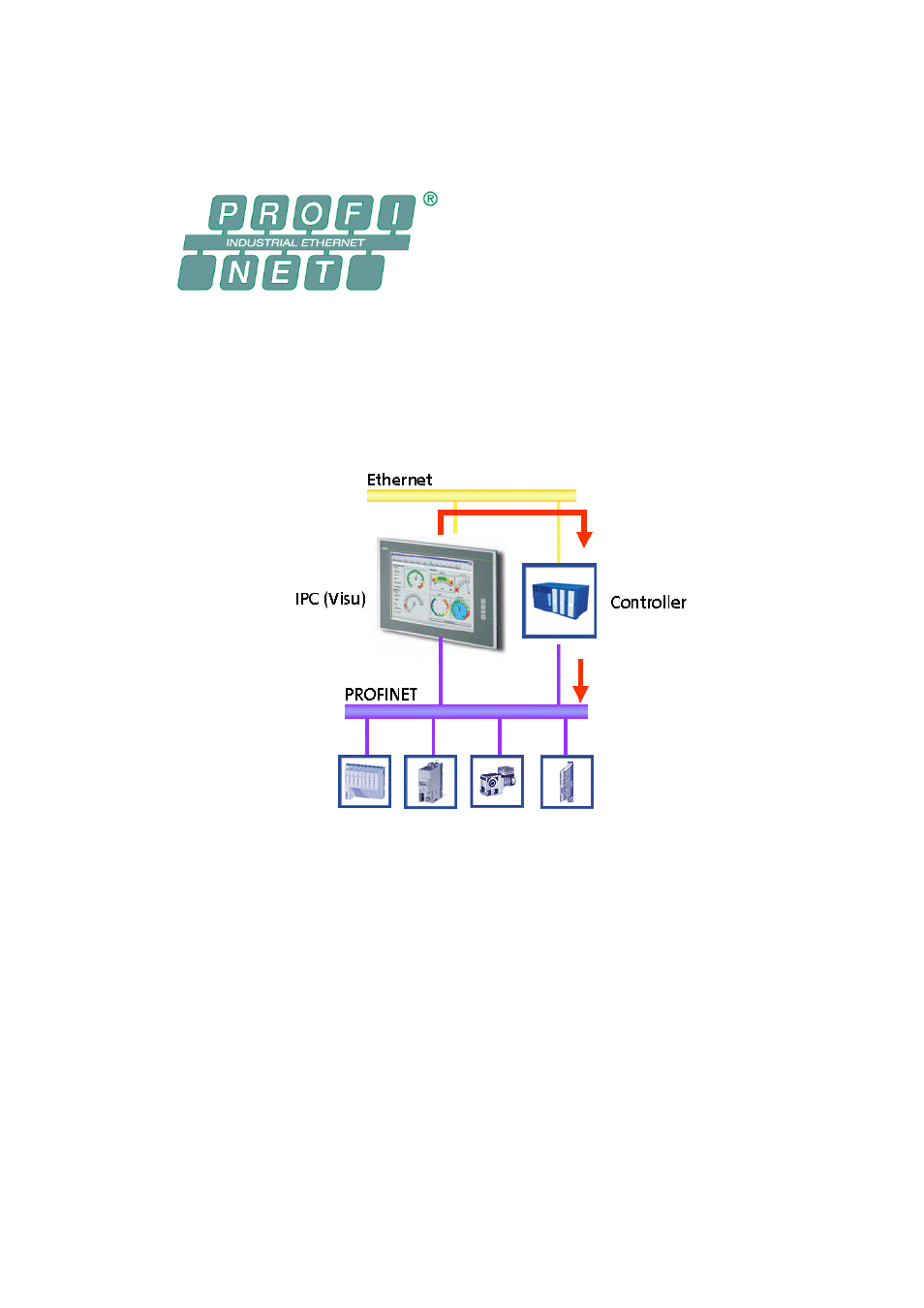

[4-2]

Basic structure of a visualisation system with PROFINET

Here, the PROFINET property is used, that each PROFINET switch allows for the connection of

standard Ethernet devices to PROFINET and real time on the bus is nevertheless ensured. This

provides the possibility of using the RFC1006 protocol (MPI via TCP/IP). The advantages of this

solution are that no special PROFINET interface is required and the visualisation does not need to be

logged on explicitly as PROFINET node in the control configuration.

The Lenze Industrial PCs, the controllers, and the EL100 HMI series are provided with an "on board"

Ethernet interface suitable for connection to a PROFINET switch.

To facilitate the creation of applications in »VisiWinNET®«, all variables can be imported from an S7-

PLC program. Communication drivers are available for all runtime systems.