3 runtime software, 1 "logic" and "motion" runtime software, Runtime software – Lenze Controller-based Automation User Manual

Page 20: Logic" and "motion" runtime software, 4system description

4

System description

4.2

System components

20

Lenze · Controller-based Automation - Visualisation · System Manual · DMS 1.5 EN · 04/2014 · TD17

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

4.2.3

Runtime software

The Industrial PC is the core of the visualisation system. To perform the tasks required, the Industrial

PC requires the so-called "runtime software".

The runtime software for instance comprises the operating system (Windows® CE). Moreover,

further software components are required which, for example, execute the control tasks of the IPC

or the visualisation application of the different applications.

These software versions are available:

• "Logic": Sequence control in the controller, motion control in the inverter

• "Motion": Sequence control and motion control in the controller, inverter as actuating drive

• "Visu": visualisation of the automation system, can be used separately or in addition to "Logic"

or "Motion"

An external monitor panel/display can be connected to the Cabinet Controller 3231 C/3241 C.

• Without software: controller as single component with operating system only

The runtime software and the licence required for using the software are usually ordered together

with the Industrial PC.

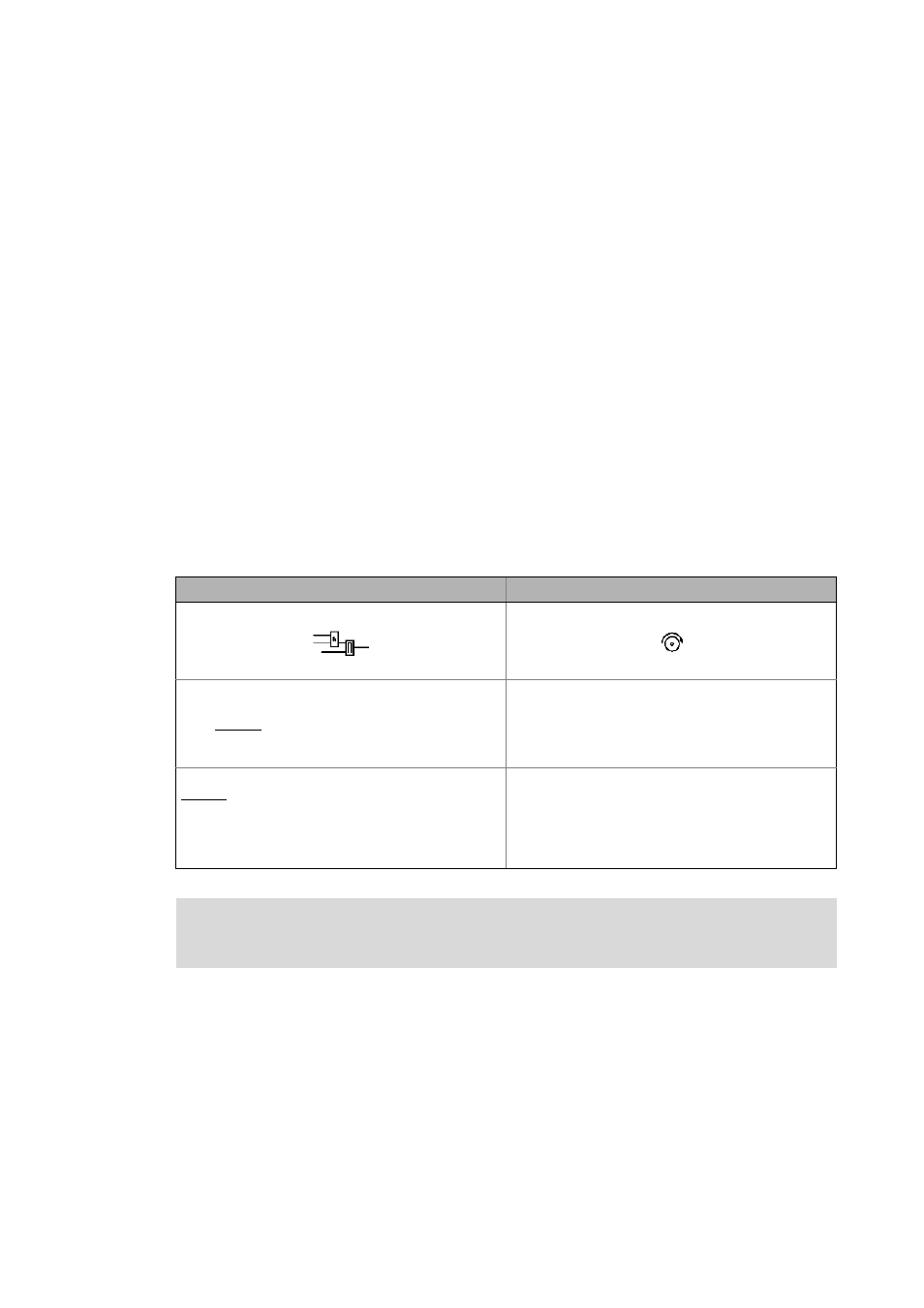

4.2.3.1

"Logic" and "Motion" runtime software

Logic

Motion

The controller controls...

• simple motion sequences;

• by logically combined control signals.

The controller controls extensive motion sequences.

The runtime software "Motion" ...

• contains the PLCopen library;

• contains the "Logic" mode;

• supports "SoftMotion".

Logic applications are suitable for the control of inverters

without a Motion functionality which ...

• execute simple motion sequences;

• can only be controlled via PLC functionality.

Motion applications are suitable...

• for the control of inverters executing complex motion

sequences of multi-axes in several dimensions;

• ...for the control of devices that are to traverse

synchronously;

• for the transfer of setpoints.

"Controller-based Automation" system manual

Here you'll find more information relating to the "Logic" and "Motion" runtime software.